Piezoelectric precision linear driving platform based on stick-slip inertia

A linear drive and inertial technology, applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., can solve the problems of short service life, short life, small movement stroke, etc. Achieve the effect of low cost, high speed and fast motion speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

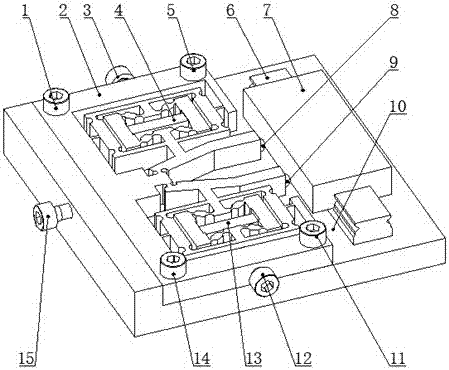

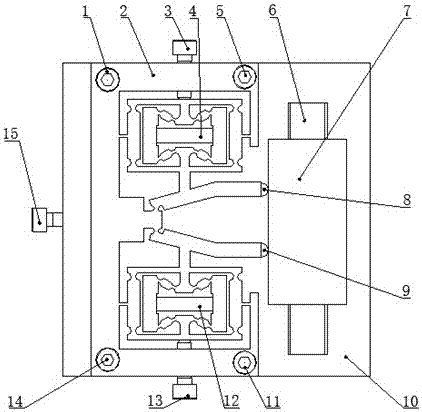

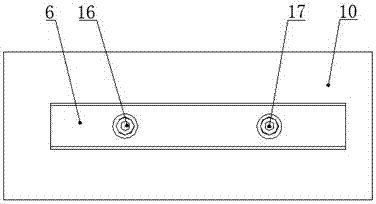

[0017] The detailed content of the present invention and its specific implementation will be further described below in conjunction with the accompanying drawings.

[0018] see Figure 1 to Figure 4 As shown, the piezoelectric precision linear drive platform based on the stick-slip inertia of the present invention can output displacement through the fast feed mode or the precision feed mode: in the early stage of motion, the fast feed mode is adopted because the mover slider is far away from the target position , that is, apply a sawtooth wave to the piezoelectric stack to achieve rapid displacement; in the later stage of the movement, because the mover slider is closer to the target position, a precision feeding method is adopted, that is, a continuous voltage is applied to the piezoelectric stack, and it can be combined with a displacement sensor Closed-loop feedback realizes precise micro-feeding motion. It includes a drive unit, a motion unit and a pretension unit, wherei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com