A plane speaker

A flat-panel loudspeaker and loudspeaker technology, applied in the field of loudspeakers, can solve the problems of complex, enlarged rigid flat panel area, and high manufacturing cost of honeycomb panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

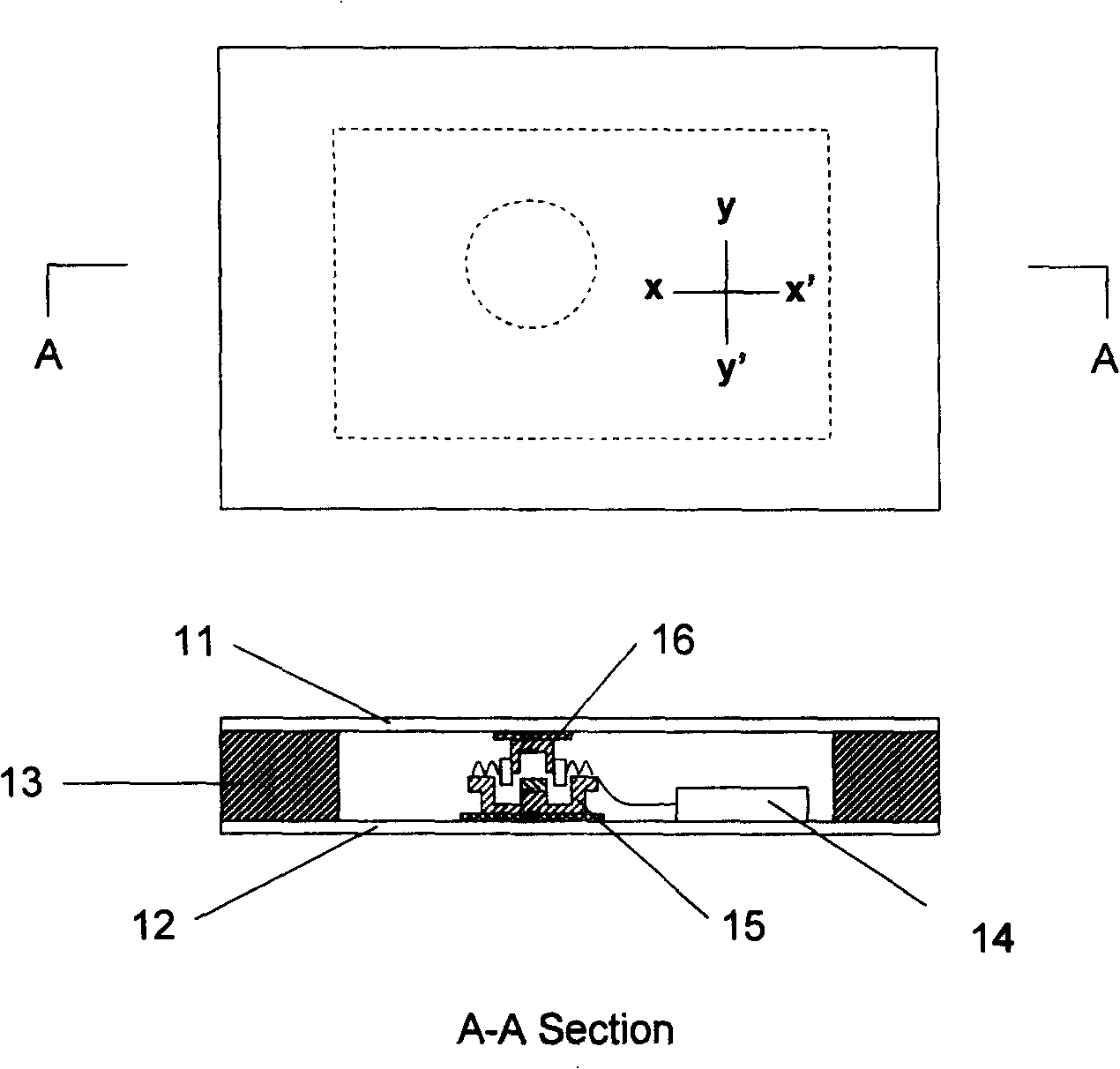

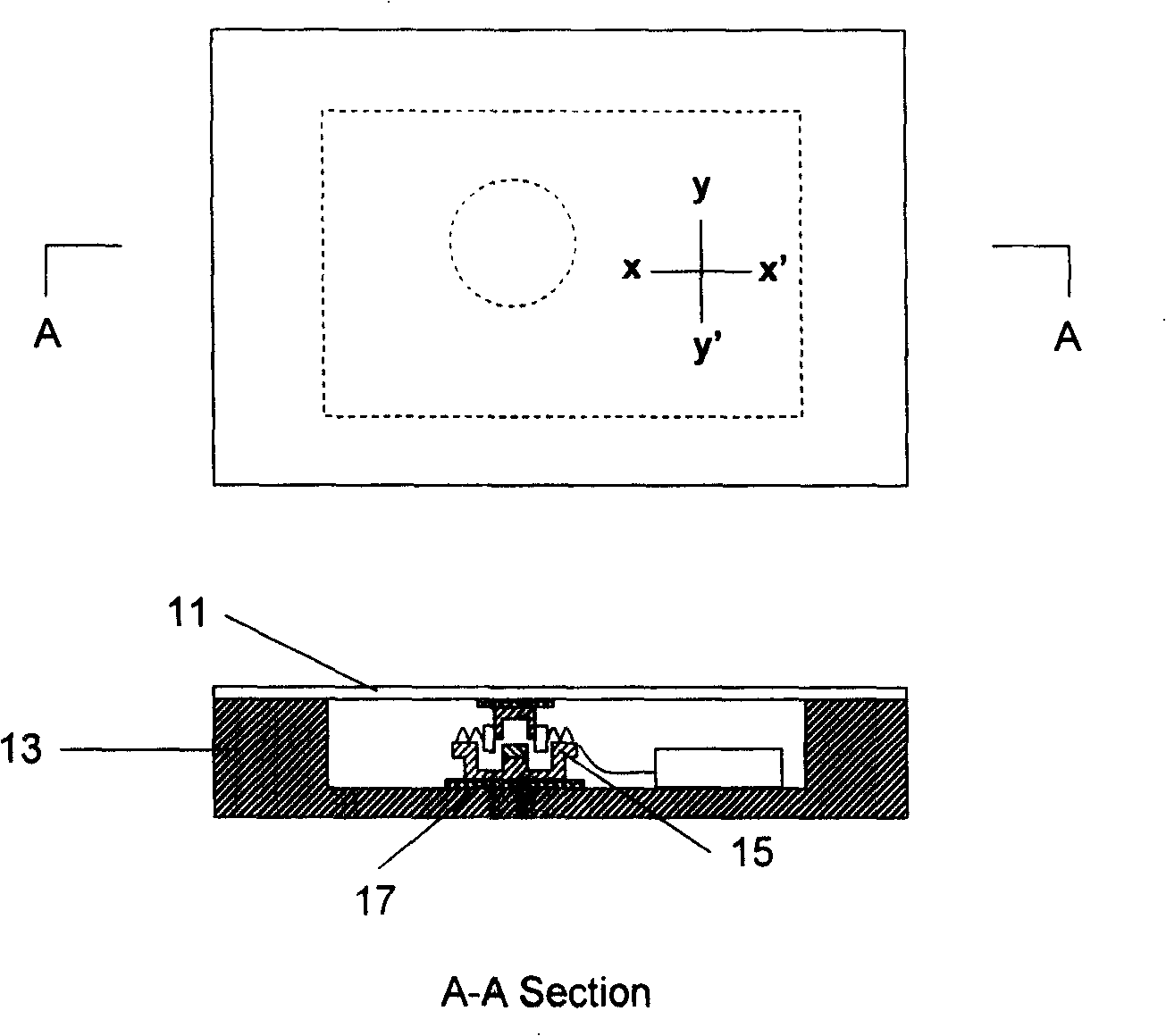

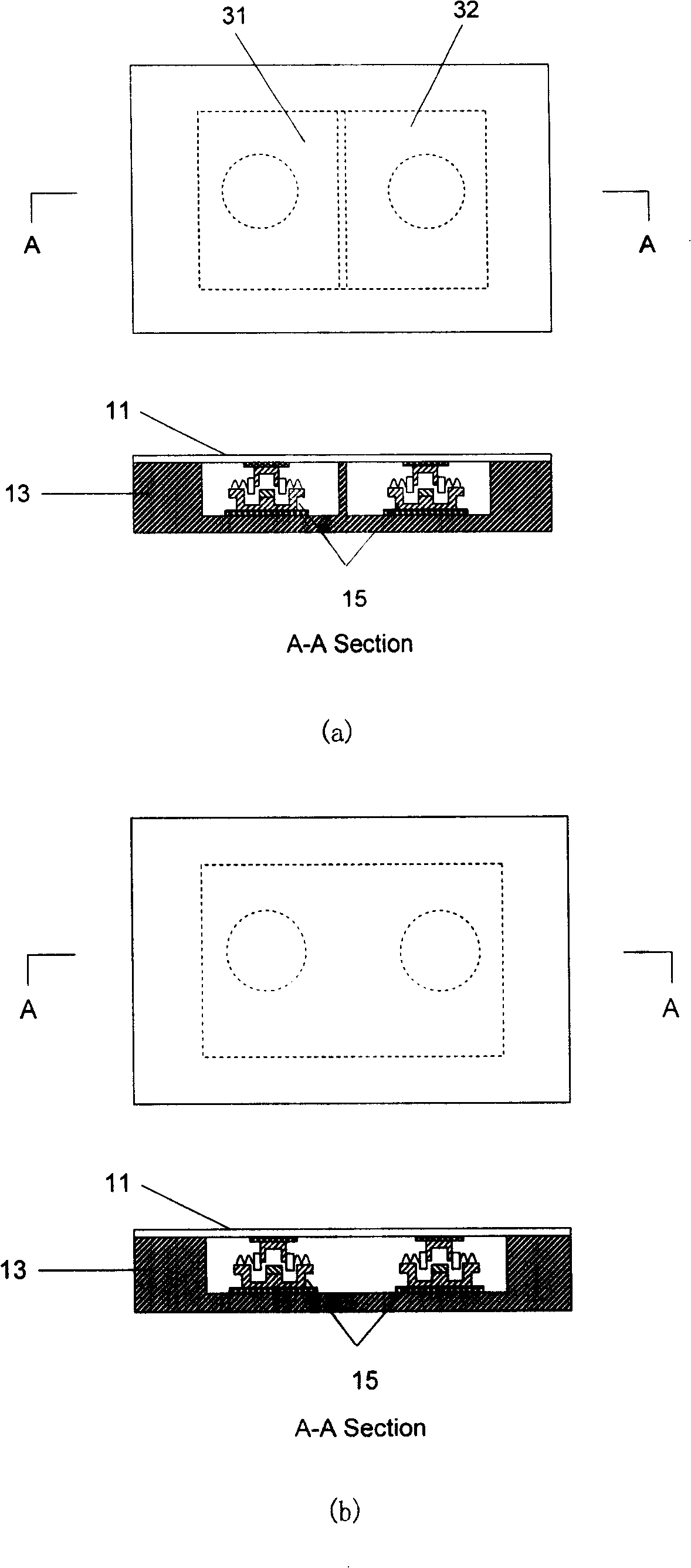

[0010] Such as figure 1 As shown, a planar loudspeaker includes a front surface diaphragm 11 and a rear surface diaphragm 12; the diaphragm has a flexible and bendable feature, and it can be various types of polymers, such as: polyimide (polyimide) film or Polyester film, or various thin cardboards, or various thin metal plates, such as aluminum foil or copper foil. The diaphragm is fixed to the frame 13 after being stretched by a pre-tightening force along at least one direction (x-x' or y-y' direction). As a result of the pre-tension stretching, a certain pre-stress is formed inside the film, and these tensile stresses can adjust the frequency response of the loudspeaker, especially the mid- and high-frequency responses. According to the current invention, the output sound pressure and frequency response of the loudspeaker can be adjusted by changing the diaphragm preload and surrounding constraints; increasing the diaphragm preload can enhance its mid- and high-frequency r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com