Veneer sticking equipment for wood processing

A technology of veneering and equipment, which is applied in the direction of wood processing appliances, manufacturing tools, and the joining of wooden veneers. The effect of consumption, guaranteed removal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

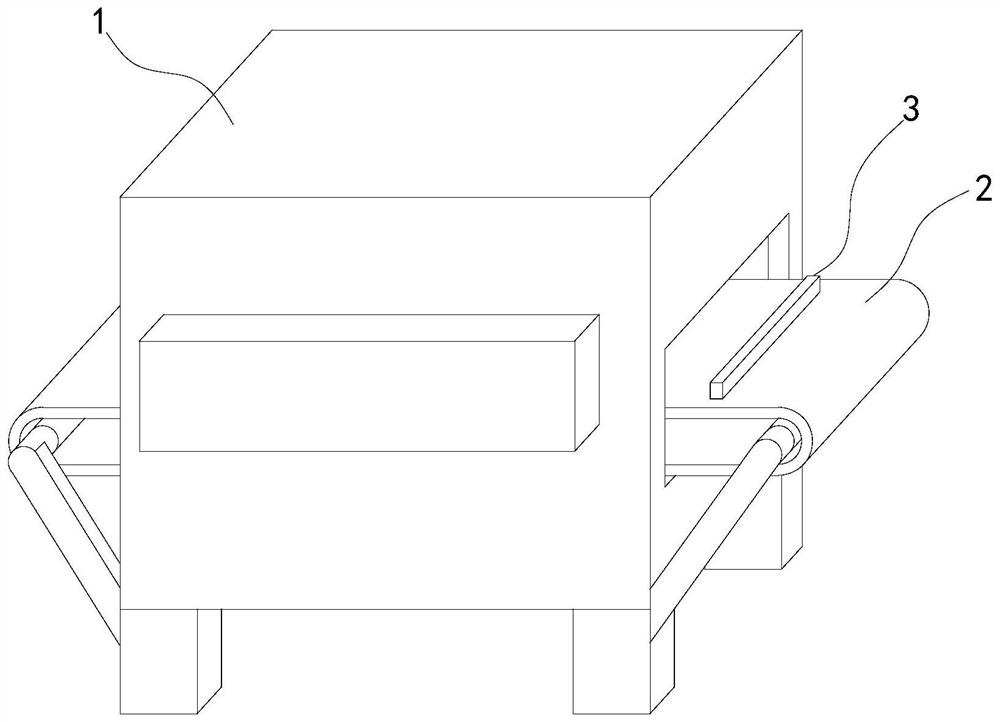

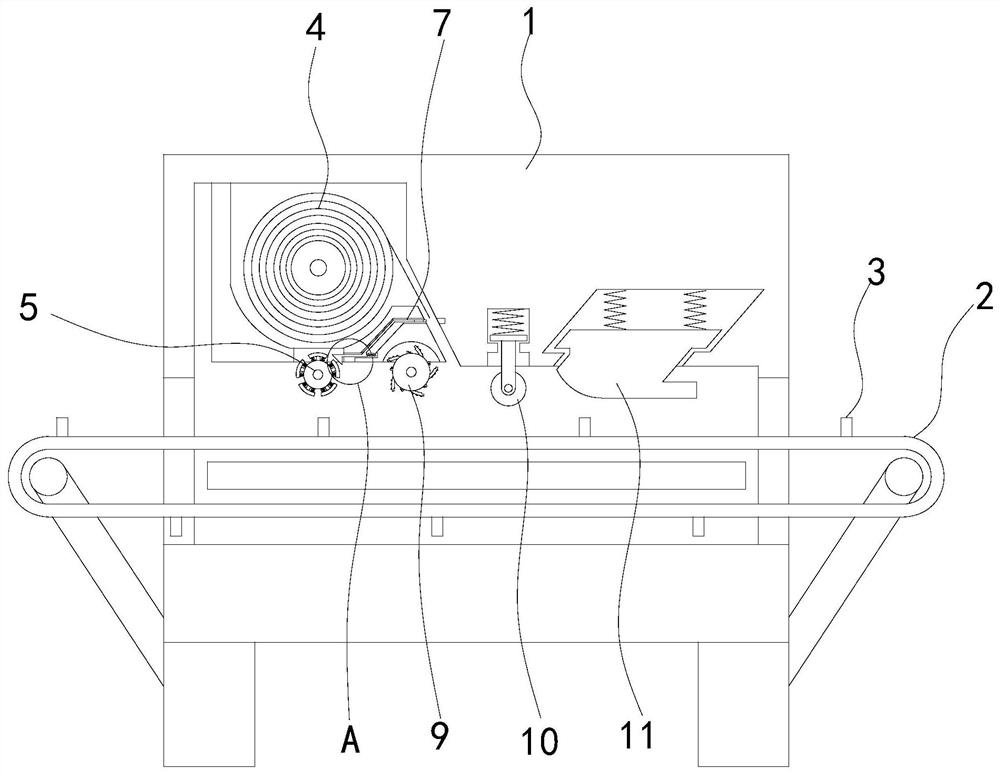

[0028] see Figures 1 to 8 , a schematic diagram of planar structure and schematic diagram of three-dimensional structure of a veneering equipment for wood processing.

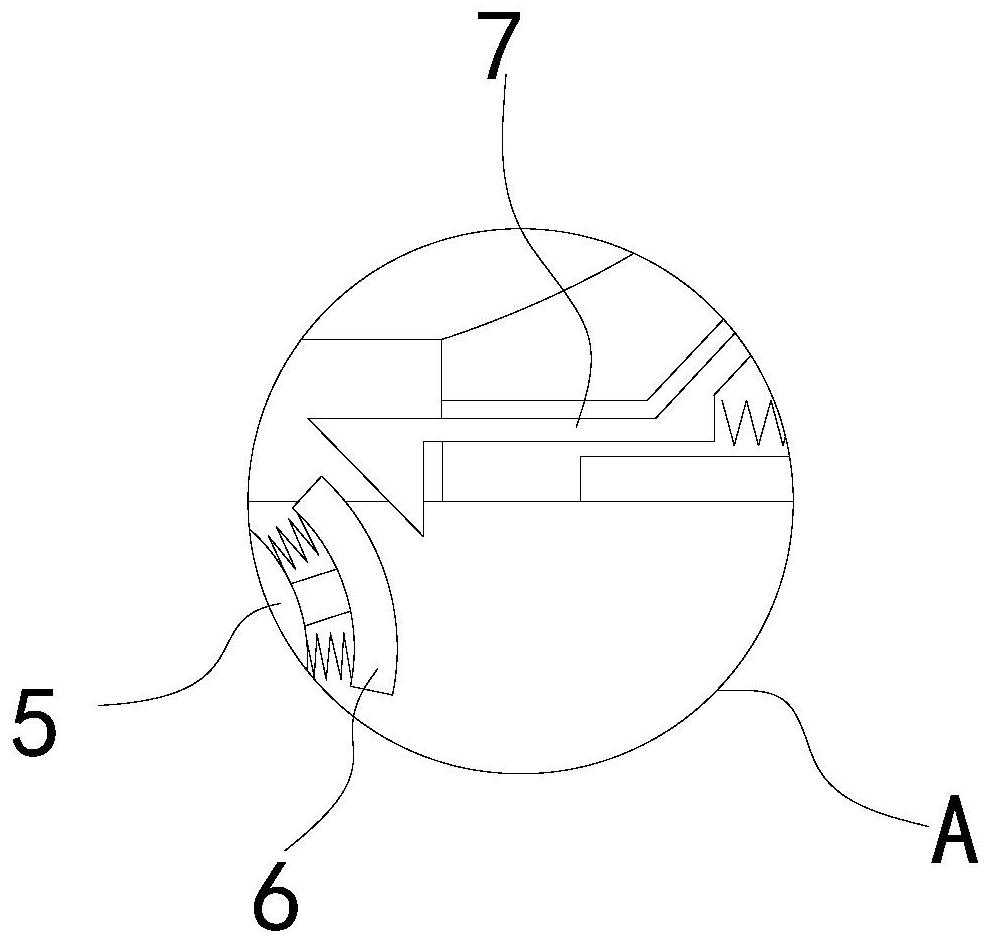

[0029] A kind of skinning equipment for wood processing, comprising a device main body 1, a conveyor belt 2 is movably installed at the lower end of the device main body 1, a touch runner 5 is movably installed inside the device main body 1 on the left side, and a lamination plate 6 is movably installed outside the touch runner 5 , The left side of the device main body 1 is fixedly equipped with a gluing runner 9, and a scraper 17 is movably installed on the outside of the gluing runner 9.

[0030] In a specific implementation, a veneer roll 4 is movably installed on the upper end of the device main body 1, the touch runner 5 is arranged directly below the veneer roll 4, and a rotating shaft 8 is movably installed at the middle end of the touch runner 5, so that when the wood is on the conveyor belt 2 When en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com