Gas turbine pressurizing air supply system

A technology for sealing air and gas turbines, which is applied in the direction of gas turbine devices, cooling of engines, cooling of turbines/propulsion devices, etc., and can solve problems such as power loss of gas turbines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

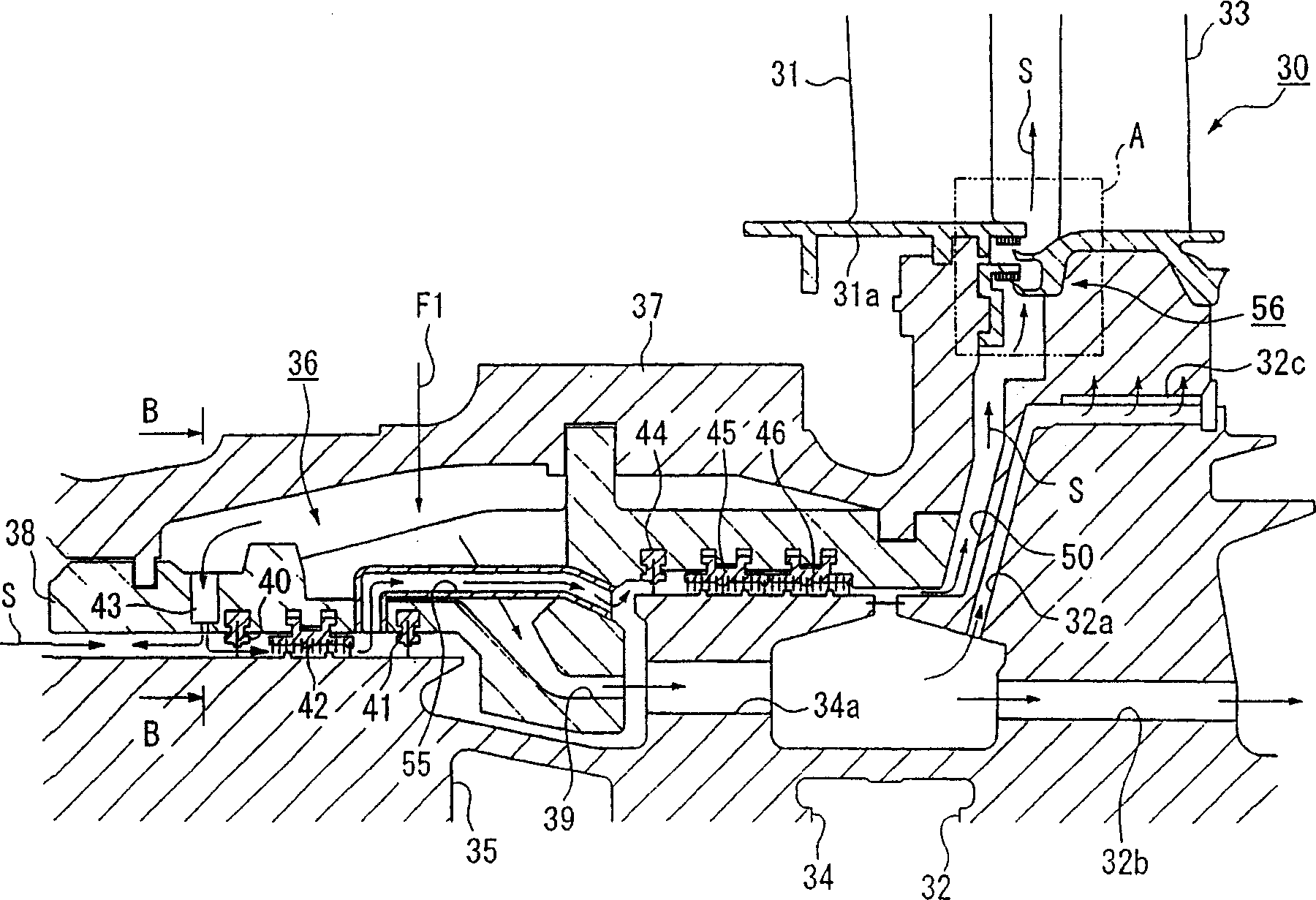

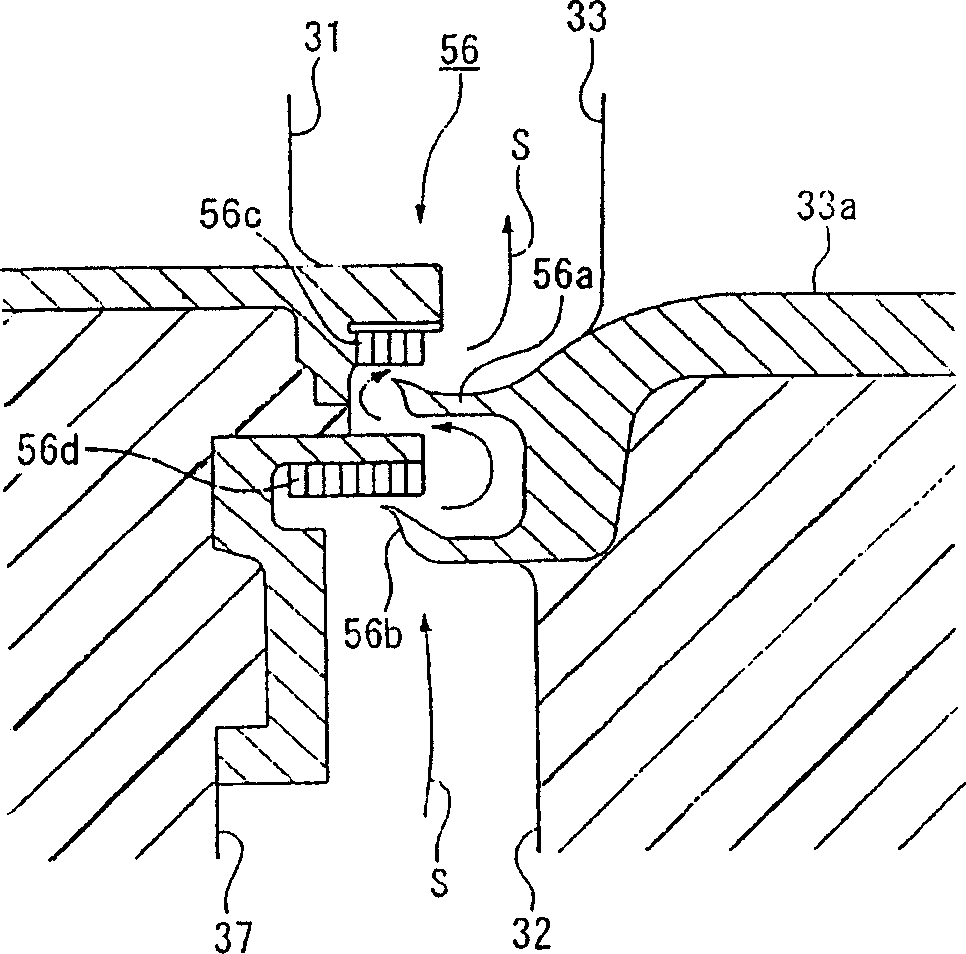

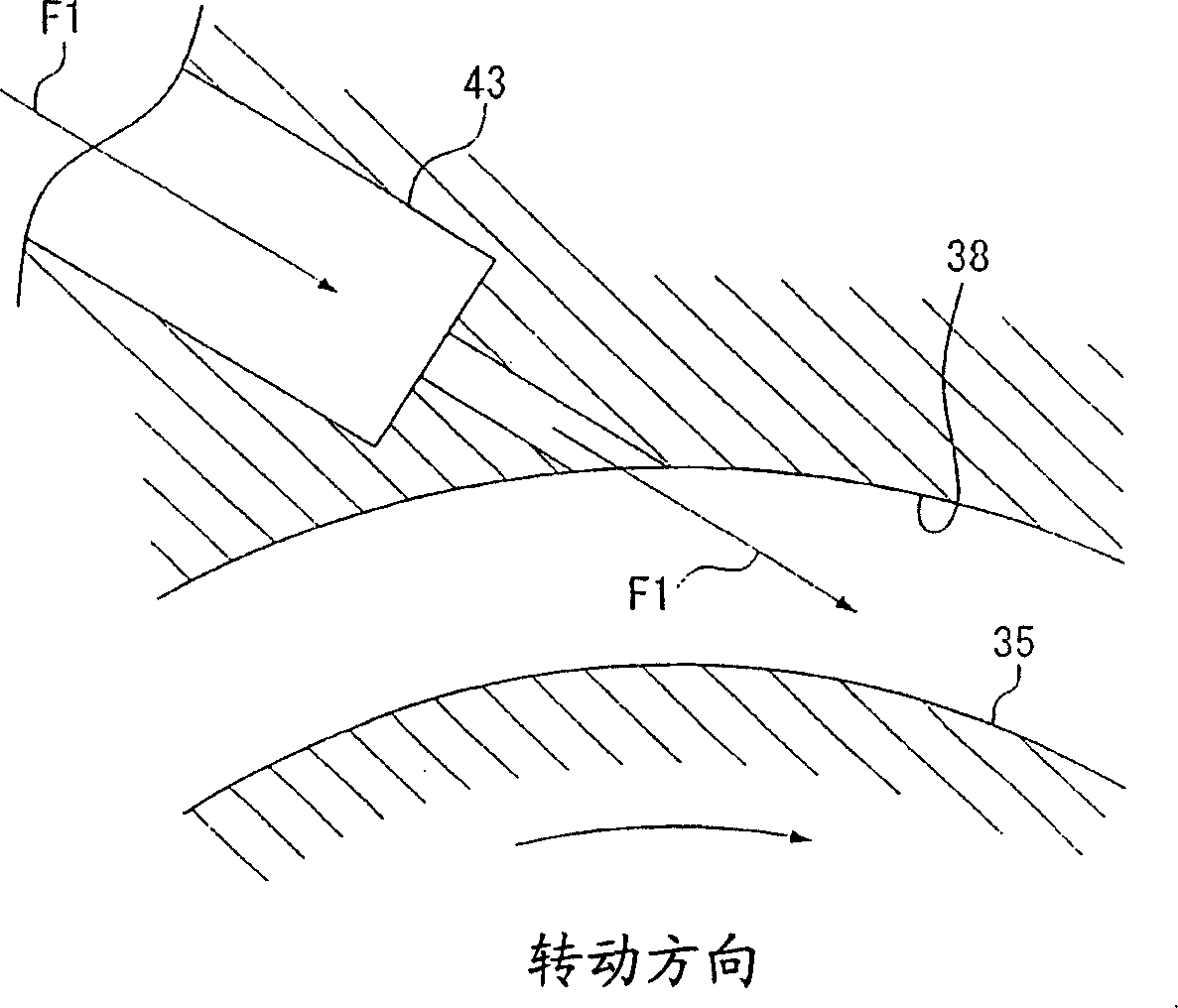

[0023] refer to Figure 1-3 Embodiments of the gas turbine of the present invention will be explained. Of course, the present invention is not limited thereto.

[0024] Note that in the following discussion, the upstream side (i.e. figure 1 The flow direction of the sealing air S and the discharge air F1 on the left side of the paper) is located on the downstream side (ie figure 1 The flow directions of the seal air S and the discharge air F1 on the right side of the paper) are referred to as "upstream side" and "downstream side", respectively. In addition, the direction of the axis of rotation of the rotating member including the sealing disk 34 and the first set of rotor disks 32 ( figure 1 Left and right in ) are referred to as "axial" in the following discussion.

[0025] like figure 1 As shown, the gas turbine of the present invention is provided with a first-stage device 30, which has: first-stage stationary blades 31 (stationary blades), which are arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com