High-power and high-speed electric spindle

A high-speed electric spindle and high-power technology, applied in the direction of large-scale fixed members, clamping, support, etc., can solve the problems of limited effect, limited cooling effect, high performance requirements of lubricating grease, etc., to achieve enhanced lubrication effect, improve rotation efficiency, Avoid the effect of taking off the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

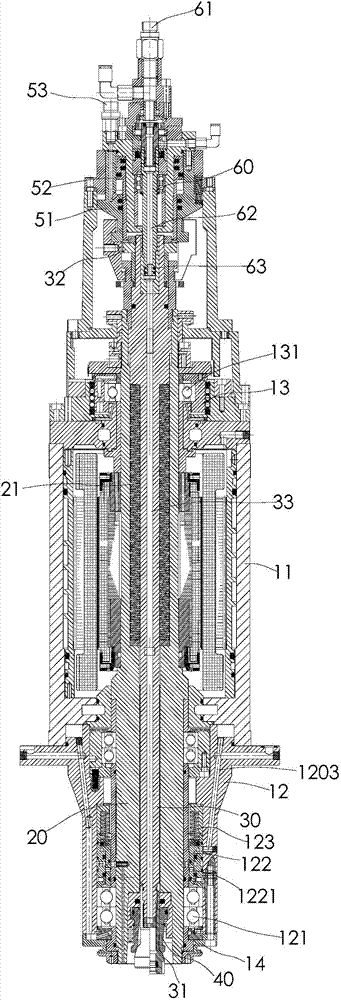

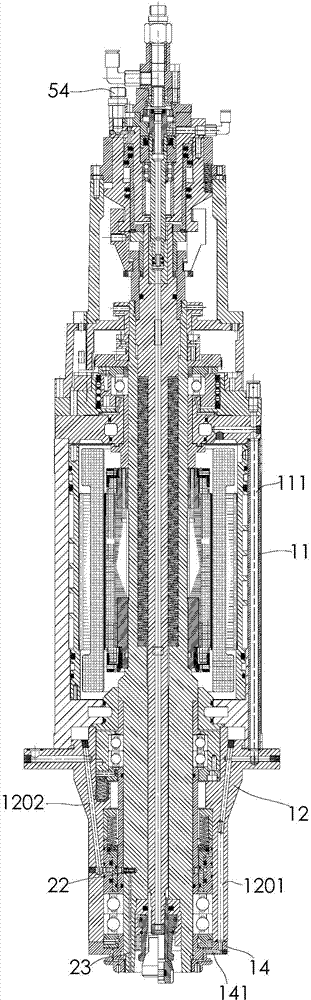

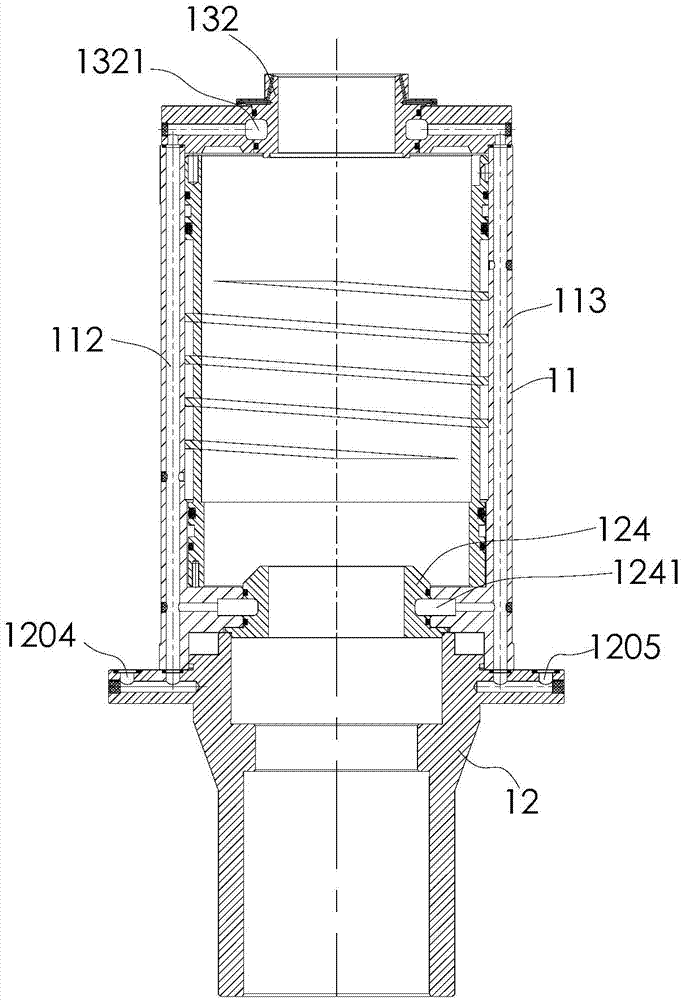

[0038] Such as figure 1 and figure 2As shown, the high-power high-speed electric spindle of the present invention includes a body assembly, a shaft core 20, a pull claw 40, a pull rod 30, a rotary joint assembly and an air blowing channel, and the body assembly includes a body 11 and an upper bearing installed on the top of the body 11 The seat assembly 13 , the lower bearing seat assembly 12 installed on the lower part of the machine body 11 and the end cover 14 connected to the lower end of the lower bearing seat assembly 12 . The shaft core 20 is connected to the inside of the machine body 11, its upper end is pivotally connected to the upper bearing seat assembly 13 through the upper bearing 131, and its lower end is pivotally connected to the lower bearing seat assembly 12 through the lower bearing 121, and the lower end of the shaft core 20 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com