Preparation method of dry process strontium ferrite magnetformed through dry process

A strontium ferrite and dry forming technology is applied in the field of preparation of dry forming strontium ferrite magnets, which can solve the problems of low remanence, high residual non-magnetic substances and high addition amount, and achieves high production efficiency, The effect of improving strength and orientation, and adding less amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

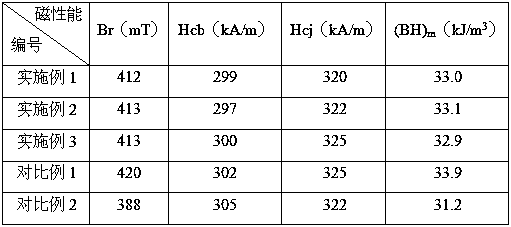

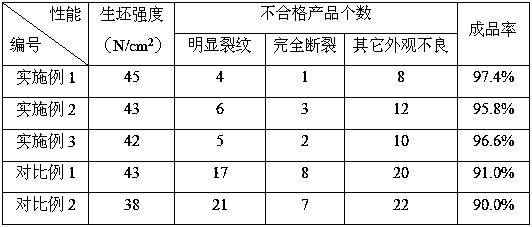

Examples

Embodiment 1

[0039] (1) Add 35kg of water to 65kg of strontium ferrite pre-fired material, and then add 3.25kg of CaCO 3 , 1.95kgAl 2 o 3 and 1.95kgH 3 BO 3 , and carried out wet ball milling for 15 hours to obtain strontium ferrite slurry;

[0040] (2) The strontium ferrite slurry obtained in step (1) was wet-pressed to a density of 2.8 g / cm in a magnetic field of 8000 Oe at a pressure of 16 MPa 3 , to obtain a cylindrical strontium ferrite green body with a diameter of 40mm and a thickness of 20mm;

[0041] (3) drying the strontium ferrite green body obtained in step (2) at 100° C. for 10 h, and then crushing to obtain oriented magnetic blocks;

[0042] (4) Add 0.2 kg of stearic acid amide with a particle size of 325 mesh and 0.2 kg of oleic acid amide with a particle size of 325 mesh to the magnetic block with orientation obtained in step (3), disperse, pulverize, and sieve to the particle size Diameter ≤ 60 mesh, get anisotropic powder;

[0043] (5) Dry press the anisotropic pow...

Embodiment 2

[0045] (1) Add 38kg of water to 62kg of strontium ferrite pre-fired material, and then add 3.50kg of CaCO 3 and 2.00kg SiO 2 , perform wet ball milling for 13 hours to obtain strontium ferrite slurry;

[0046] (2) The strontium ferrite slurry obtained in step (1) was wet-pressed to a density of 3.0 g / cm in a 10,000 Oe magnetic field at a pressure of 20 MPa 3 , to obtain a cylindrical strontium ferrite green body with a diameter of 40mm and a thickness of 18mm;

[0047] (3) drying the strontium ferrite green body obtained in step (2) at 120°C for 8 hours, and then crushing to obtain oriented magnetic blocks;

[0048] (4) Add 0.2 kg of stearic acid amide with a particle size of ≤325 mesh and 0.3 kg of oleic acid amide with a particle size of ≤325 mesh to the magnetic block with orientation obtained in step (3), disperse, pulverize, and sieve to the particle size Diameter ≤ 60 mesh, get anisotropic powder;

[0049] (5) Dry press the anisotropic powder obtained in step (4) to ...

Embodiment 3

[0051] (1) Add 38kg of water to 62kg of strontium ferrite pre-fired material, and then add 3.00kg of CaCO 3 and 1.85kg SiO 2 , perform wet ball milling for 12 hours to obtain strontium ferrite slurry;

[0052] (2) The strontium ferrite slurry obtained in step (1) was wet-pressed to a density of 2.9 g / cm in a magnetic field of 7000 Oe at a pressure of 18 MPa 3 , to obtain a cylindrical strontium ferrite green body with a diameter of 40mm and a thickness of 21mm;

[0053] (3) drying the strontium ferrite green body obtained in step (2) at 120° C. for 6 hours, and then crushing to obtain oriented magnetic blocks;

[0054] (4) Add 0.1 kg of stearic acid amide with a particle size of ≤300 mesh and 0.4 kg of oleic acid amide with a particle size of ≤300 mesh to the magnetic block with orientation obtained in step (3), and disperse, pulverize, and sieve to the particle size Diameter ≤ 40 mesh, get anisotropic powder;

[0055] (5) Dry press the anisotropic powder obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com