Disposable lunchbox extrusion forming device

An extrusion molding, one-time technology, which is applied in the direction of household components, household appliances, and other household appliances, can solve the problems of prolonging the waiting time of workers, reducing the production efficiency of lunch boxes, and the inability to cool lunch boxes, so as to achieve good cooling, The effect of safe and convenient use and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the examples.

[0020] The following examples are used to illustrate the present invention, but cannot be used to limit the protection scope of the present invention. The conditions in the embodiment can be further adjusted according to the specific conditions, and the simple improvement of the method of the present invention under the premise of the concept of the present invention belongs to the protection scope of the present invention.

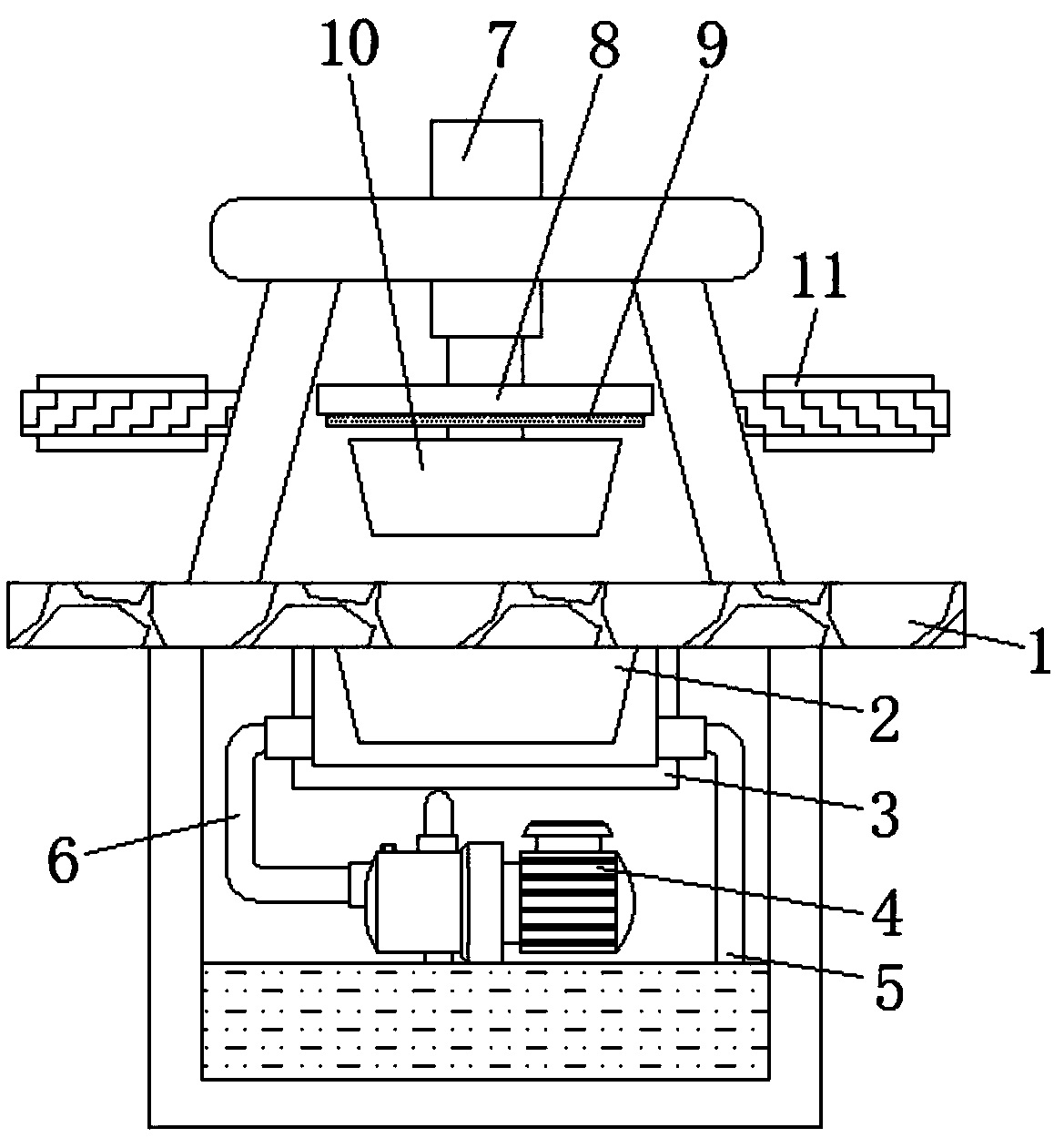

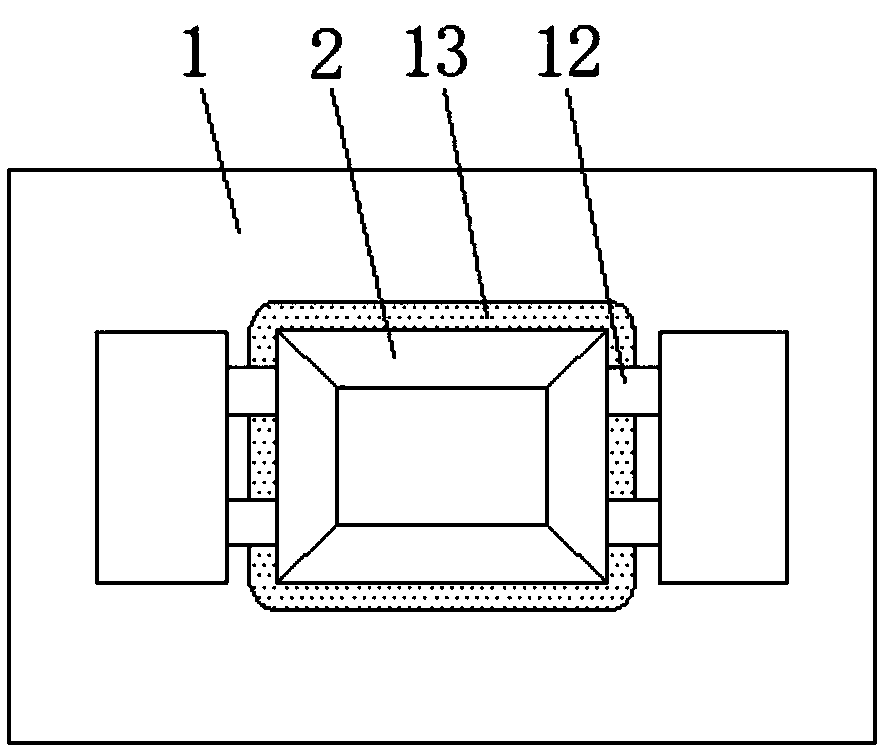

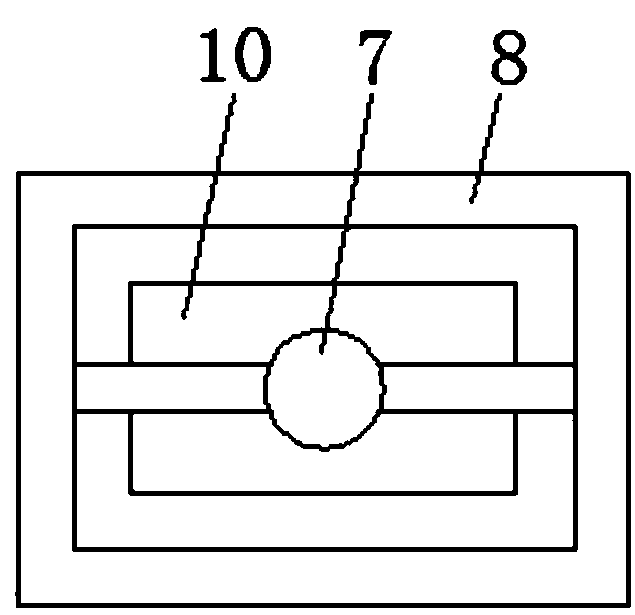

[0021] see Figure 1-3 , the present invention provides a technical solution: a disposable lunch box extrusion molding device, including a support plate 1, the upper surface of the support plate 1 is clamped with a mold box 2, and the bottom end of the mold box 2 passes through the support plate 1 And be positioned at the bottom of base plate, the upper surface of support plate 1 is provided with groove 13, and the shape of groove 13 is square, and groove 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com