Functional gradient thermal barrier coating and preparation method thereof

A technology of thermal barrier coatings and functional gradients, which is applied in coatings, metal material coating processes, etc., can solve the problems of short thermal cycle life and achieve high crystallinity, good bonding strength, and controllable thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

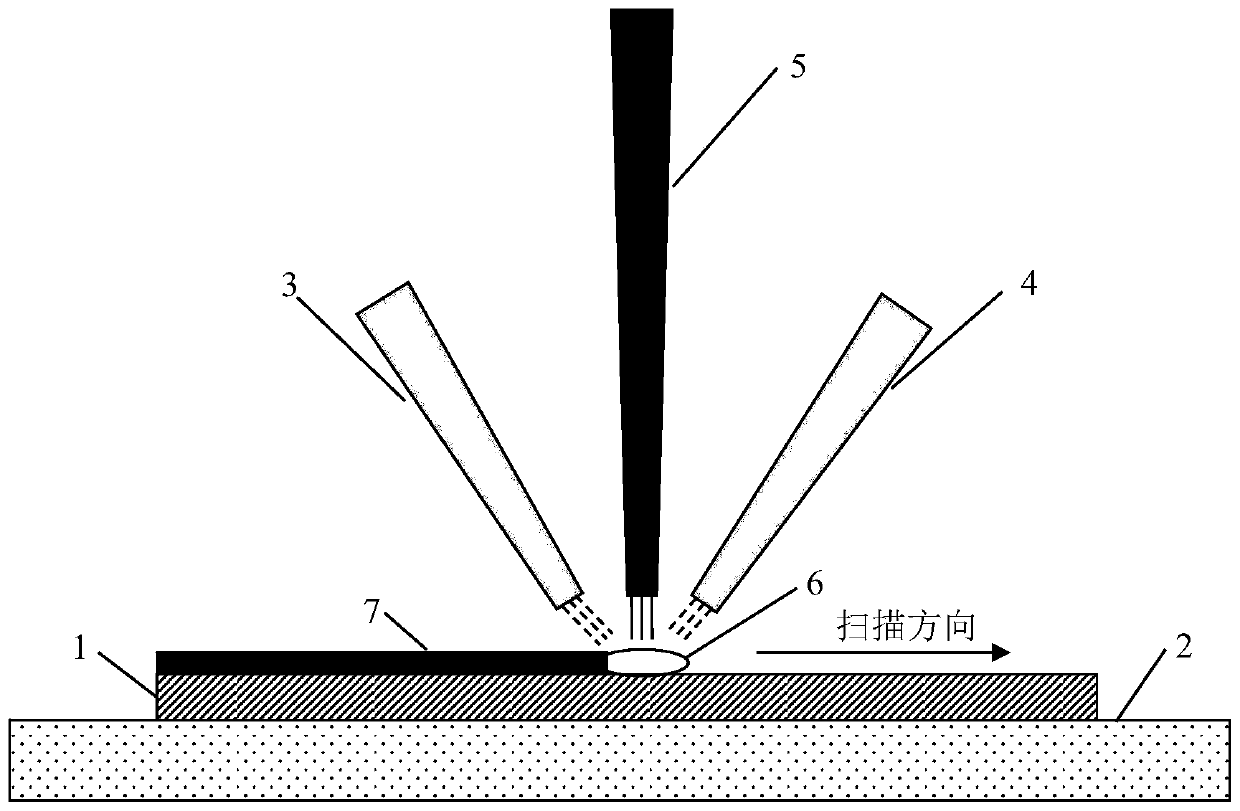

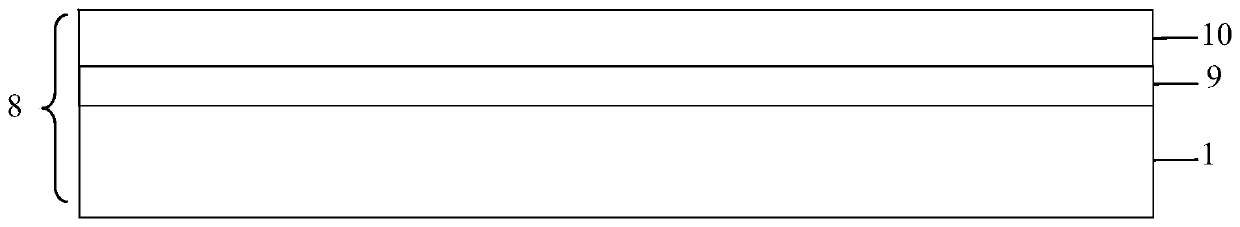

[0036] A method for preparing a functionally graded thermal barrier coating provided by the present invention comprises the following steps:

[0037] Step (1), purifying and roughening the surface of the nickel-based superalloy substrate;

[0038] Purification treatment is to remove oxides, oil stains and other pollutants on the surface of the substrate.

[0039] Further, the surface purification treatment can use 320-800 mesh sandpaper to remove surface oxides, and then use acetone and absolute ethanol solution to ultrasonically clean the oil stains and other pollutants on the surface of the substrate.

[0040] Further, the surface roughening treatment may use corundum sand pressurized wet sandblasting to roughen the surface of the substrate, and then sequentially use acetone and absolute ethanol solution to ultrasonically clean the residual corundum sand on the substrate surface, and dry the substrate for use.

[0041] Further, the corundum sand can be 80-360 mesh, the sand...

Embodiment 1

[0051] The 3D model of the thermal barrier coating is established in the computer, and the model is layered according to the composition gradient of the pre-prepared coating, and the scanning path is planned for each layer and converted into a numerical control program for mechanical operation.

[0052] Before preparing the coating: cut the DZ411 nickel-based superalloy wire into a substrate 1 with a size of 40mm×40mm×10mm, and round the corners of the sample. The surface of the coating to be processed on the substrate 1 was polished with 320-mesh and 800-mesh sandpaper in sequence, and then placed in acetone and absolute ethanol solutions for ultrasonic cleaning for 30 minutes to remove surface oil stains and other pollutants; use 120-mesh corundum sand at 0.3 After performing wet sandblasting on the above surface under MPa pressure, place it in acetone and absolute ethanol solution for 30 minutes for ultrasonic cleaning to remove residual corundum sand on the surface. After r...

Embodiment 2

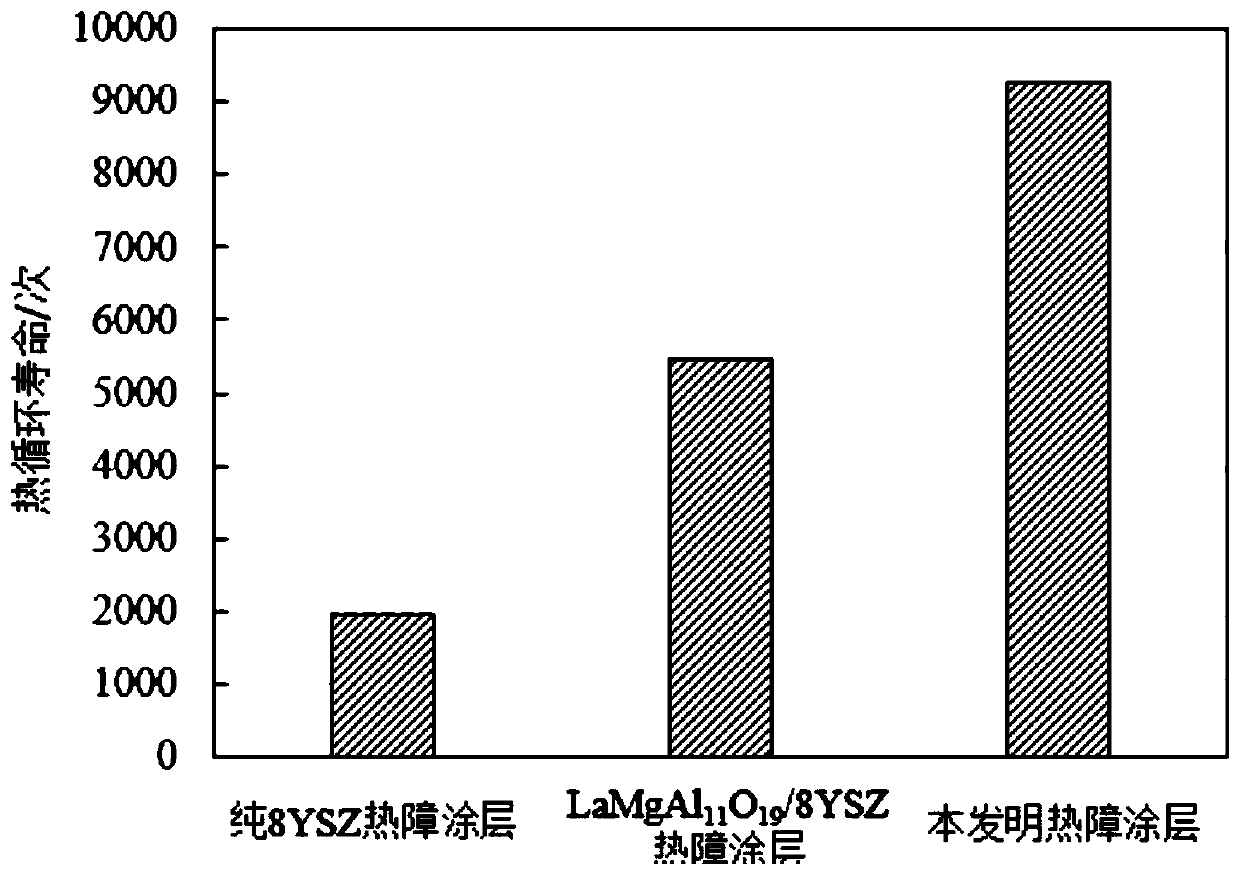

[0058] The bonding strength of functionally graded thermal barrier coatings prepared by laser near-net-shaping technology was further tested. According to the requirements of the ASTM633-01 standard, prepare the samples required for the tensile bond strength test: the sample diameter is 23-25 mm, the length is 38.1 mm, the coating thickness is > 380 μm, the number of samples is 5, and the tensile load 0.013~0.021mm·s -1 The loading rate is loaded until fracture occurs. When the tensile stress is 350 MPa, the fracture occurs in the coating. Therefore, the bonding strength of the functionally graded thermal barrier coating prepared by the laser near-net forming technology disclosed in the present invention is >350 MPa, which is much higher than that of the thermal barrier coating prepared by the traditional thermal spraying technology. The bonding strength of the barrier coating has reached the standard of metallurgical bonding.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com