In-situ integrated additive manufacturing device for nano-metal circuit

A nano-metal, additive manufacturing technology, applied in additive processing, printed circuit components, three-dimensional rigid printed circuit boards, etc., can solve problems such as low efficiency, long preparation time, and inability to freely design and manufacture electronic circuits. To achieve the effect of improving flexibility, improving density and preventing oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

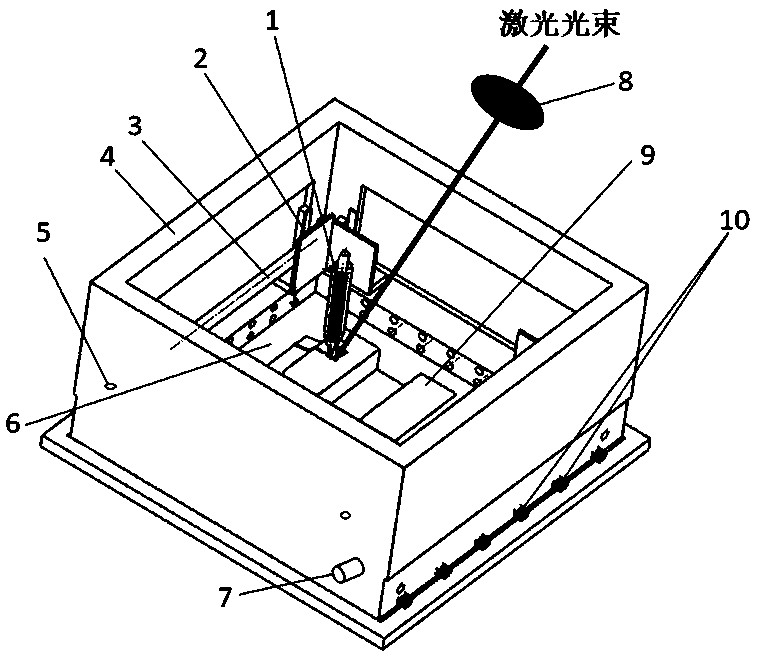

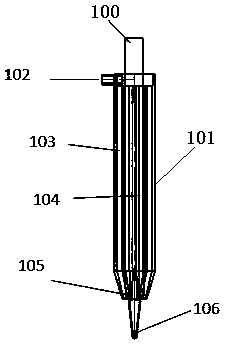

[0025] An in-situ integrated additive manufacturing device for nanometer metal circuits, comprising: a forming chamber 4, an additive feeding module 1, an in-situ irradiation reduction module, an in-situ sintering module, an in-situ heating module, and a gas protection module, wherein the forming chamber The bottom of 4 is provided with an in-situ heating module. The in-situ heating module includes a heating base plate 6 arranged at the bottom of the forming chamber. The heating base plate 6 is heated by a built-in resistance wire, and the temperature is displayed and controlled by a thermocouple, and the upper surface of the heating base plate 6 is heated. The processing platform used to place the parts to be processed, the heating bottom plate 6 described in this embodiment is fixed on the bottom of the forming chamber 4 by four adjustable spring screws, and can be le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com