Mold air and water combined cooling system and low-pressure wheel hub mold with same

A hybrid cooling and low-pressure wheel technology is applied in the field of automobile wheel hub molds, which can solve the problems of mechanical properties of product materials affecting product production efficiency, prolonged mold opening time, uneven cooling effect, etc. The effect of reducing the amount of voltage used and reducing the cost of electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

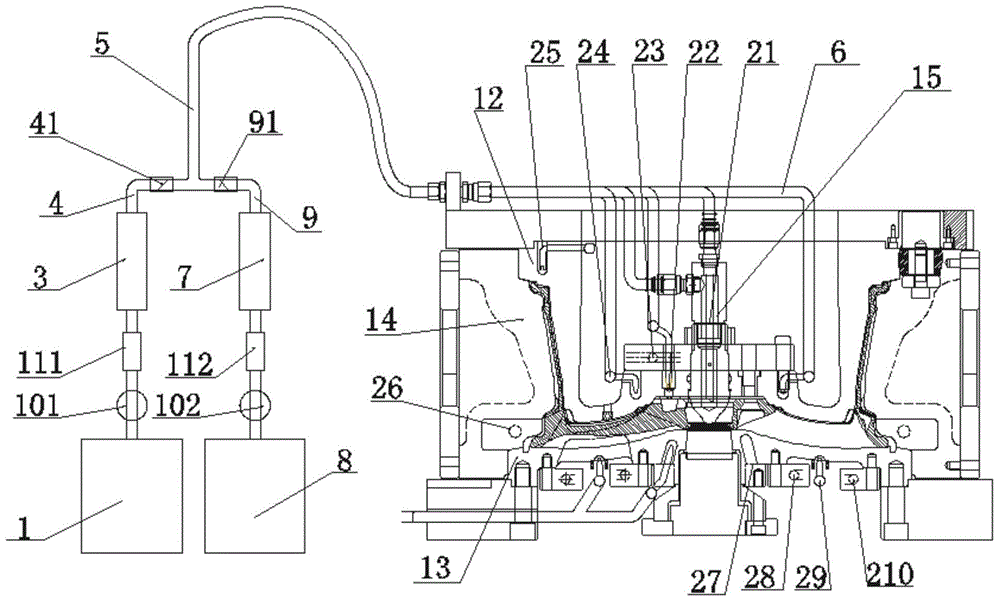

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

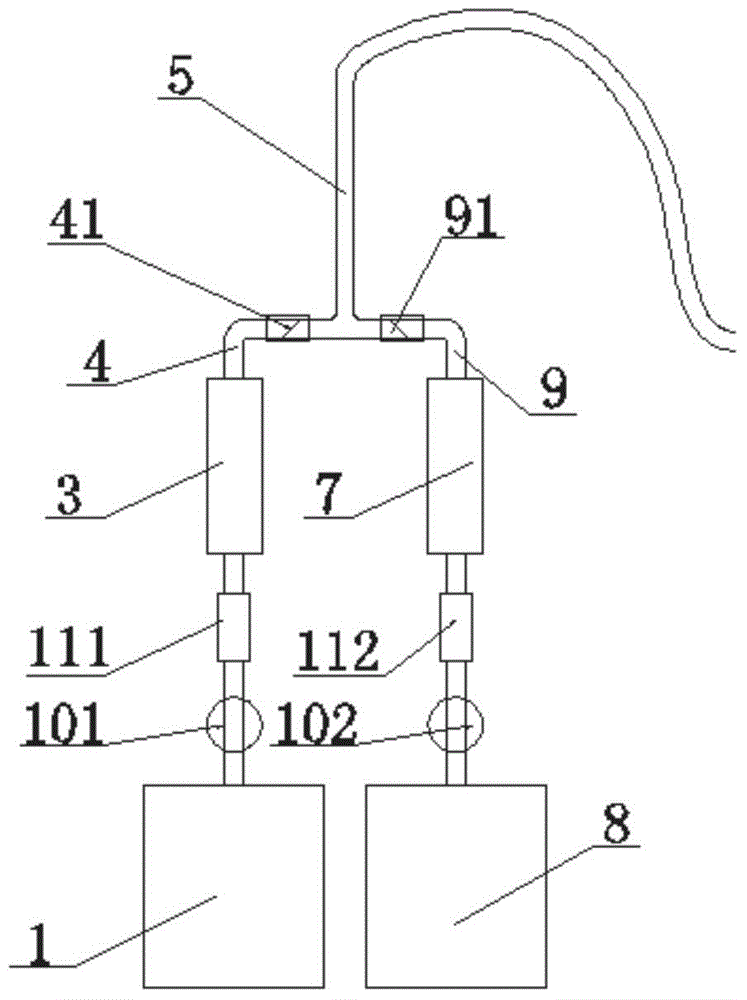

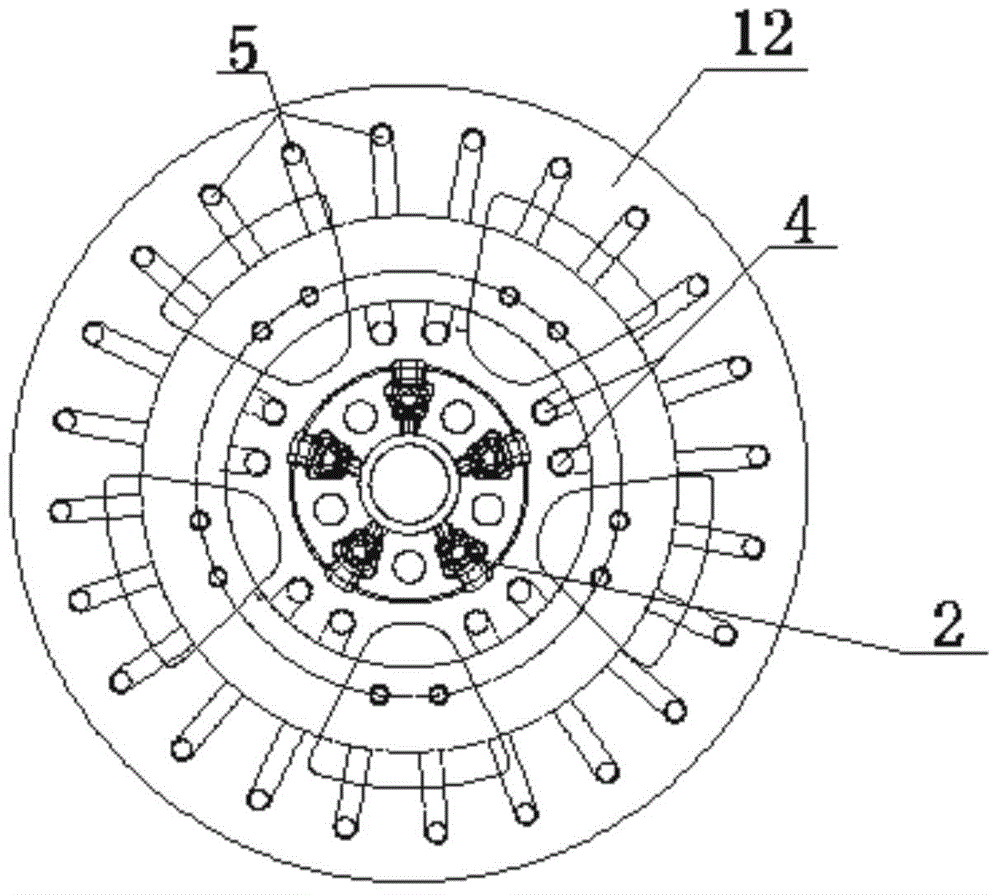

[0028] The invention provides a mold air-water mixing cooling system, such as figure 1 As shown, the system includes an external air pressure source machine 1, a first pressure gauge 101, a first flow meter 3, a first pipeline 4 and a main pipe 5, and the external air pressure source machine 1 passes through the first pipeline 4 and one end of the main pipe 5 The other end of the main pipe 5 includes no less than two shunt pipes 6; the first flowmeter 7 and the first pressure gauge 101 are arranged on the first pipe, and the shunt pipe 6 is connected to the cooling terminal of the mold. connection; the system also includes an external circulating cooling water machine 8, the external circulating cooling water machine 8 is connected to the second pipeline 9, and the second pipeline 9 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com