Automatic demolding ejection type slide-free injection mold

An automatic demoulding and injection mold technology, applied in the field of injection molds, can solve problems such as the inconvenience of mold ejection, and achieve the effect of rapid cooling molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

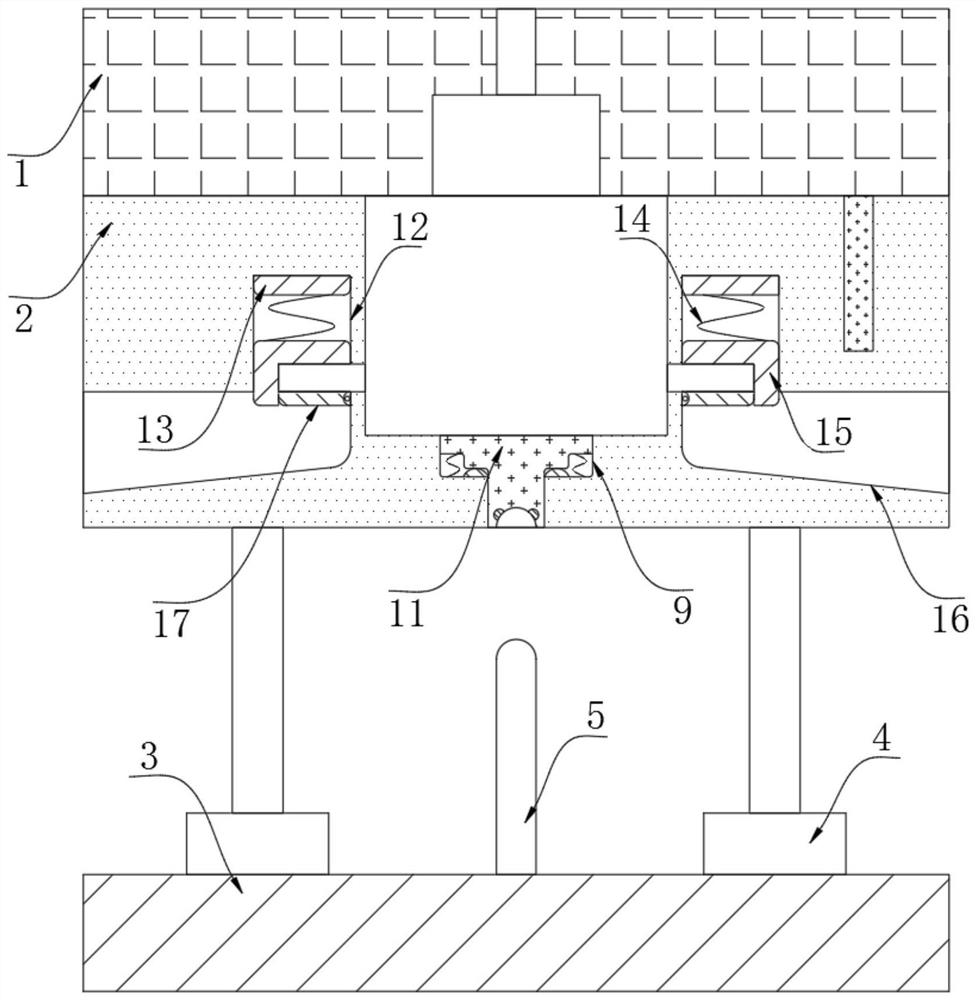

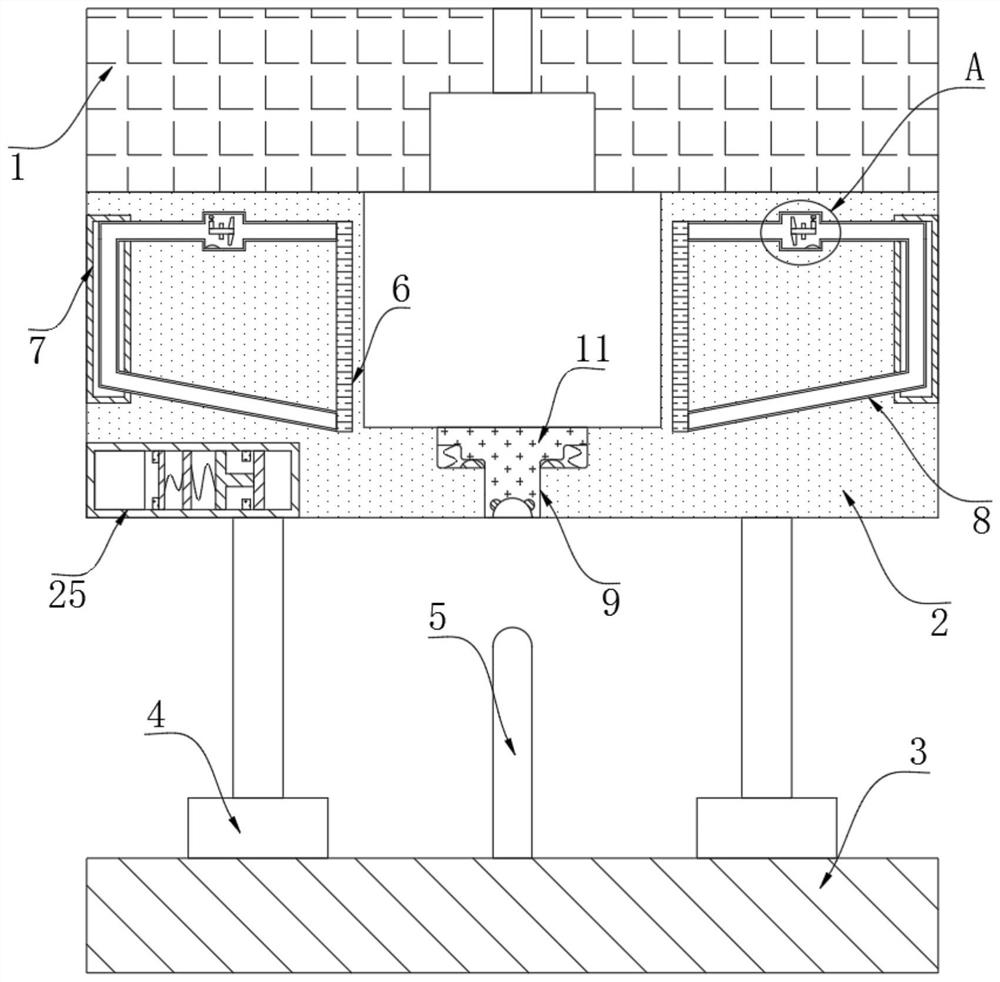

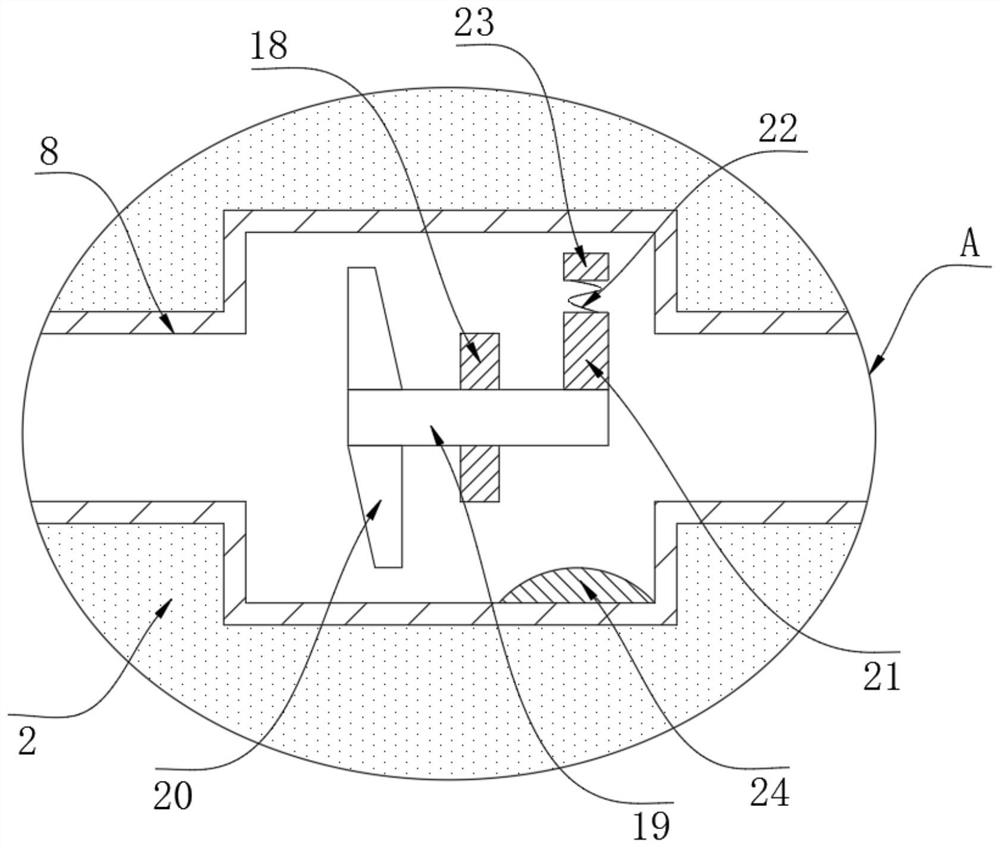

[0023] refer to Figure 1-5 , an automatic demoulding ejection type injection mold without row position, comprising a fixed mold 1, a movable mold 2 and a base 3, the upper end of the base 3 is connected with the bottom of the movable mold 2 through a plurality of telescopic rods 4, and the upper end of the base 3 is fixed with The ejector rod 5 and the side wall of the movable mold 2 are provided with multiple groups of cooling mechanisms. The cooling mechanism includes a cooling chamber 6 opened on the side wall of the movable mold 2 and a heat dissipation box 7 embedded in the side wall of the movable mold 2. The interior of the cooling chamber 6 is filled There is evaporating liquid, and the side wall of the heat dissipation box 7 is inserted with a heat dissipation pipe 8 communicating with the interior of the cooling chamber 6. Both ends of the heat dissipation pipe 8 are provided with check valves, and the interior of the heat dissipation pipe 8 is equipped with an induc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com