Optical cable production line

A production line and optical cable technology, applied in optical components, other household appliances, household appliances, etc., can solve the problems of not suitable for the transformation and use of optical cable production lines, the effect is not improved, the structure is complex, etc., to achieve high cooling and curing efficiency, avoid strain. /Scratching, efficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

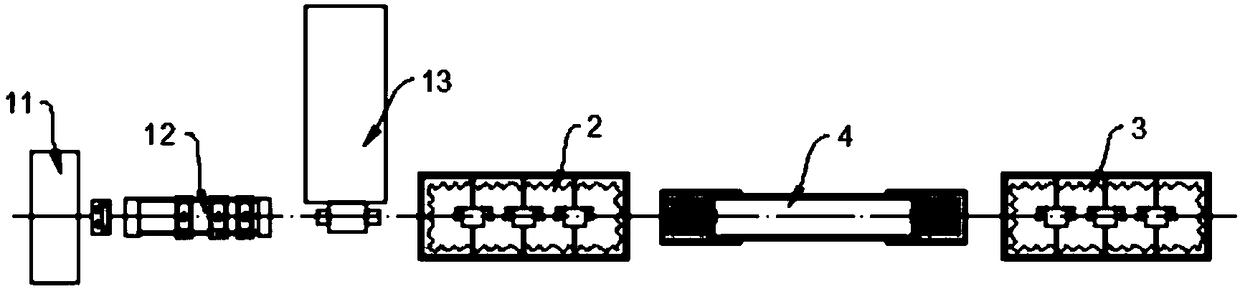

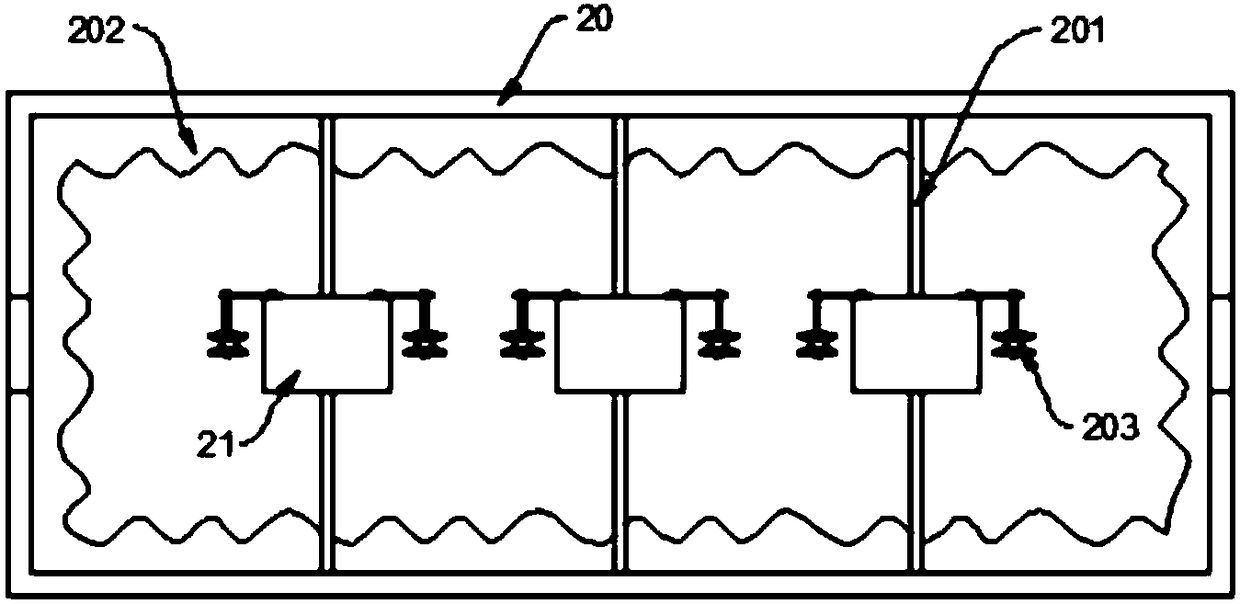

[0037] Such as figure 1 As shown, an optical cable production line includes an optical fiber pay-off device 11, a stranding device 12, an extruder 13, a cooling and solidification system, and a winding device arranged in sequence. The cooling and solidification system includes an optical cable coating and curing device 2 and an optical cable The sealing air cooling device 3 , the optical cable sealing curing device 2 and the optical cable sealing air cooling device 3 are arranged after the extruder 13 in sequence. In order to successfully complete the manufacturing and production of optical cables / optical cables, components / equipment such as a caliper, a coding device, a tension device, and a control system can also be provided. The caliper and the coding device are arranged after the cooling and solidification system. The tension device is arranged between the optical fiber pay-off device 11 and the twisting device 12, and the control system includes an electric control box, ...

Embodiment 2

[0059] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the air distributor 31 is provided with multiple groups of air-cooling nozzles 32, and each group of air-cooling nozzles 32 is arranged along the air-cooling running direction of the optical cable, that is, the axial direction of the cooling channel 310 , the inside of the wind distributor 31 corresponds to the position of each group of air-cooled nozzles 32 and is provided with a multi-section cooling channel 310, and each section of the cooling channel 310 is provided with a cooling channel inlet 311 and a cooling channel outlet 312; The diameter of the cooling channel inlet 311 of the cooling channel 310 at one end is greater than the diameter of the cooling channel outlet 312, and the inner surface of the cooling channel 310 forms a tapered surface; The diameter is equal to the diameter of the outlet 312 of the cooling channel, and the inner surface of the cooling channel 310...

Embodiment 3

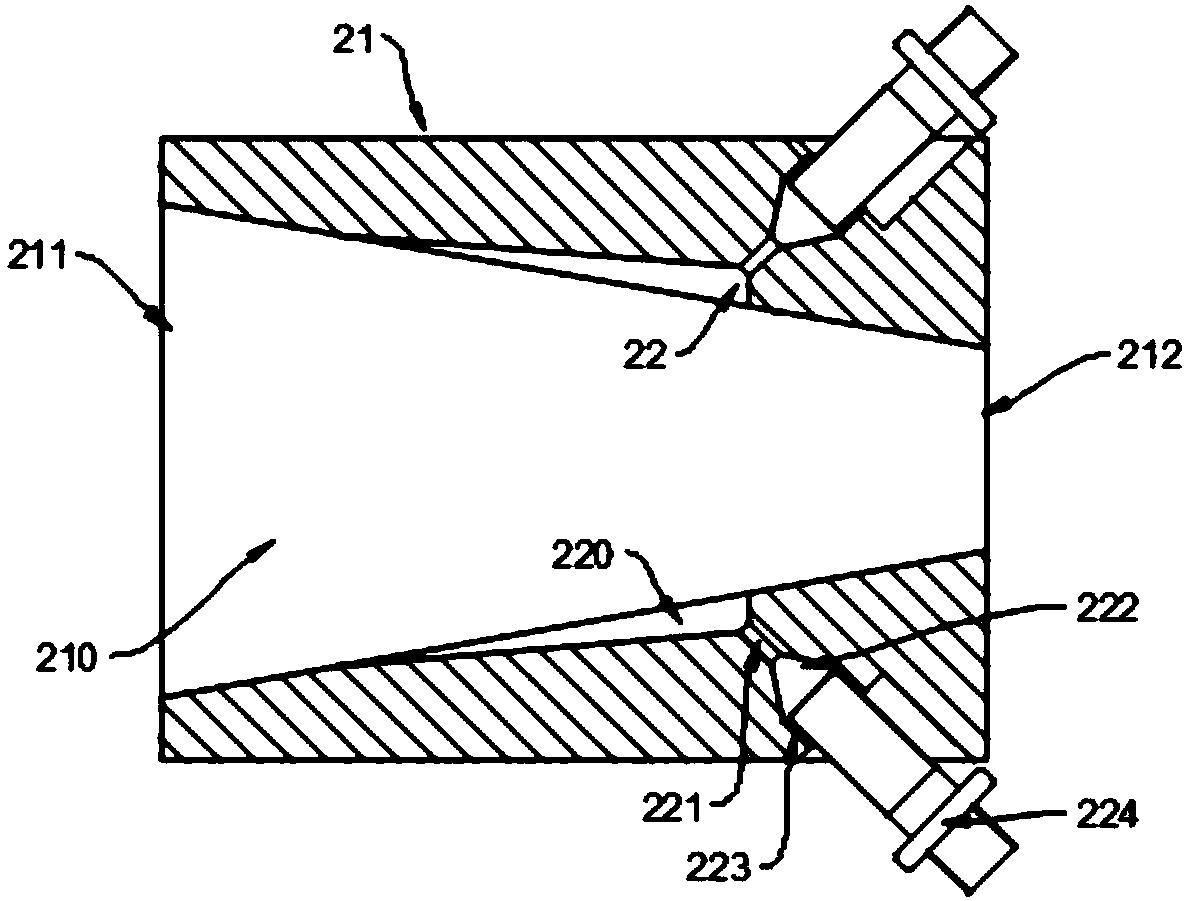

[0062] Such as Figure 9 As shown, the difference between this embodiment and Embodiment 1 is that the optical cable coating curing device 2 and the optical cable coating air-cooling device 3 are of an integrated structure, including an atomizer 21 and a wind distributor 31 arranged integrally. The curing channel 210 of the atomizer 21 has a curing channel inlet 211 and a curing channel outlet 212, and the diameter of the curing channel inlet 211 is greater than the diameter of the curing channel outlet 212, and the inner surface of the curing channel 210 forms a tapered surface; the wind force The diameter of the cooling channel inlet 311 of the cooling channel 310 of the distributor 31 is equal to the diameter of the cooling channel outlet 312 . As an option, the inner surface of the cooling channel 310 may also form a spindle-shaped surface.

[0063] It is suitable for optical cables with small diameter or thin coating layer, because it can cool down faster, requires less ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com