Garbage compression molding, cutting and granulating method

A technology of compression molding and garbage, which is applied in the field of garbage compression molding, cutting and granulation, which can solve the problems of difficult control of the length limit of garbage particles, affecting the processing process of equipment, and particle bonding, so as to ensure integrity, increase surface area, and reduce interaction wear effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

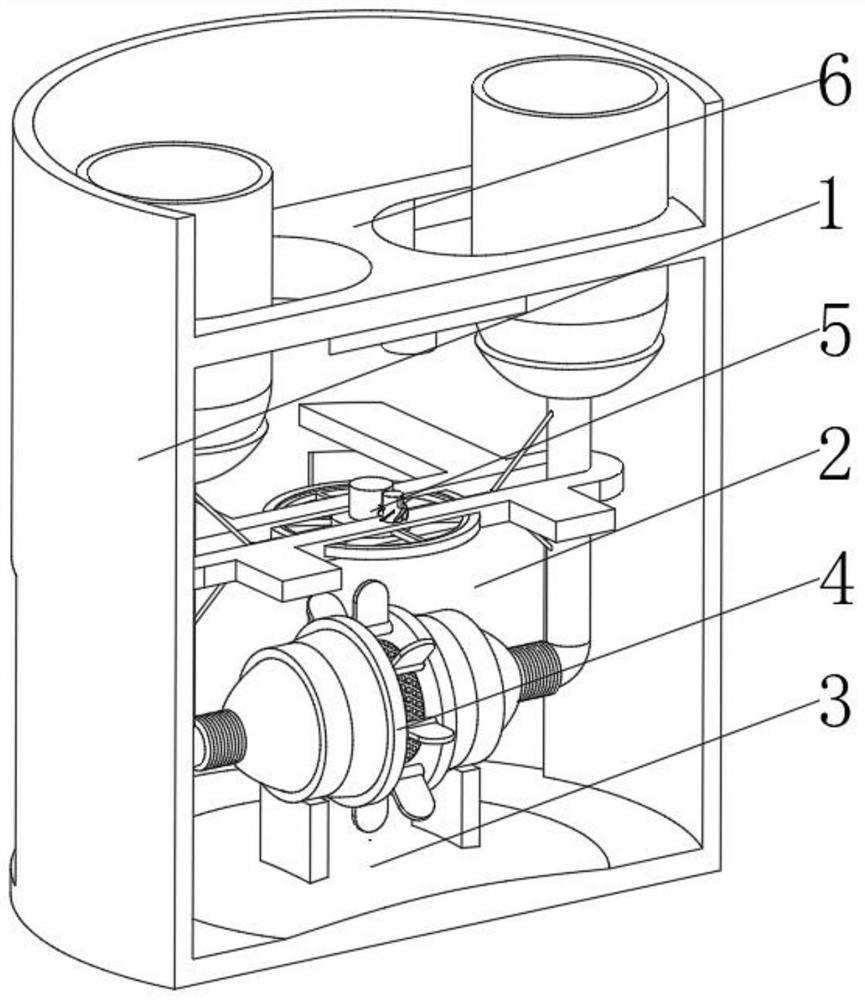

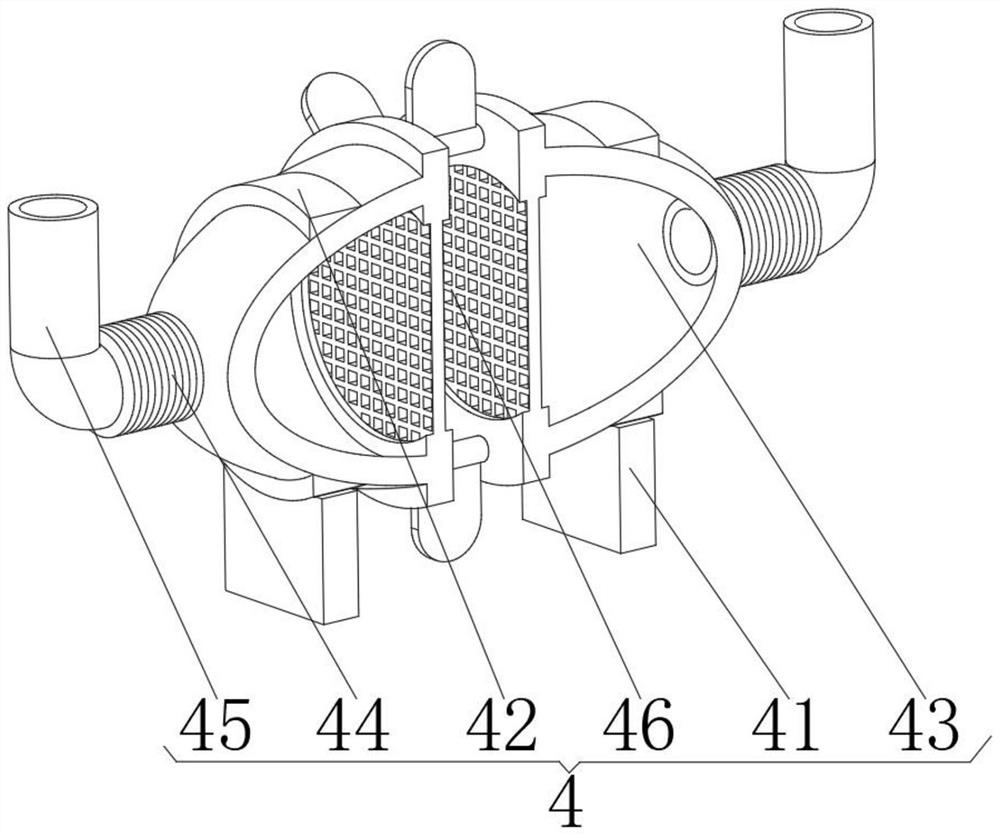

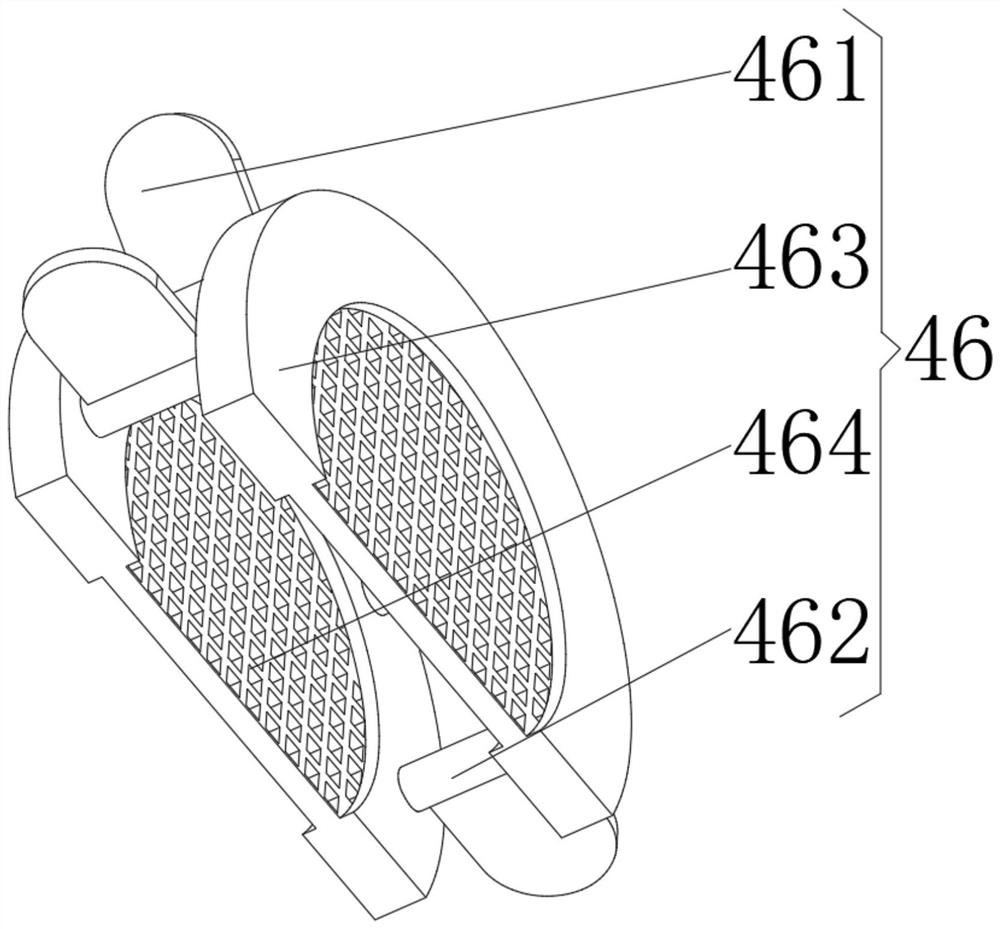

[0042] see Figure 1-5 , the present invention provides a technical solution: a garbage pressing, molding, cutting and granulating equipment, which specifically includes:

[0043] A protective box 1, the protective box 1 has a cylindrical body, and a through hole 2 opened at the bottom of the outer surface of the cylindrical body, and a material guide platform 3 installed in the middle of the bottom of the inner cavity of the cylindrical body, and a material guide platform installed on the bottom of the inner cavity of the cylindrical body. 3, the granulation device 4 on the top, the adjustment device 5 installed on the inner surface of the cylindrical main body and above the granulation device 4, and the molding device 6 installed on the top of the inner surface of the cylindrical main body, through the setting of the material guide table 3 The granulated garbage uses the impact force generated by its own falling to guide the material, avoiding the stacking of the granulated ...

Embodiment 2

[0054] see Figure 1-5 , On the basis of Embodiment 1, the present invention provides a technical solution: a method for pressing, molding, cutting and granulating garbage, characterized in that:

[0055] Step 1: start the heating tank 63, preheat the heating tank 63, start the agitator 64 to work, pour the garbage into the heating tank 63, and perform melting and mixing processing;

[0056] Step 2: transport the mixed garbage in step 1 to the hard column 57 through the feeding hole 65, and transport it to the inside of the hardened tube 45 and the spring tube 44;

[0057] Step 3: Start the blower 62 to drive the regulating device 5 and the granulating device 4 by wind power;

[0058] Step 4: The wind power drives the wind-driven page driving column 56 to rotate, and rotates the toggle column 55, so that the rotation of the toggle column 55 drives the rotating transparent plate 54 to rotate, and drives the traction rope 58 to shrink, so that the hard cylinder column 57 moves ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com