Online fusion production method of manganese-silicon alloy powder

A technology of manganese-silicon alloy and production method, which is applied in the production field of on-line molten manganese-silicon alloy powder, can solve problems such as difficulty in popularization and application, and achieve the effects of improving recycling rate, increasing power consumption, and accelerating cooling speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

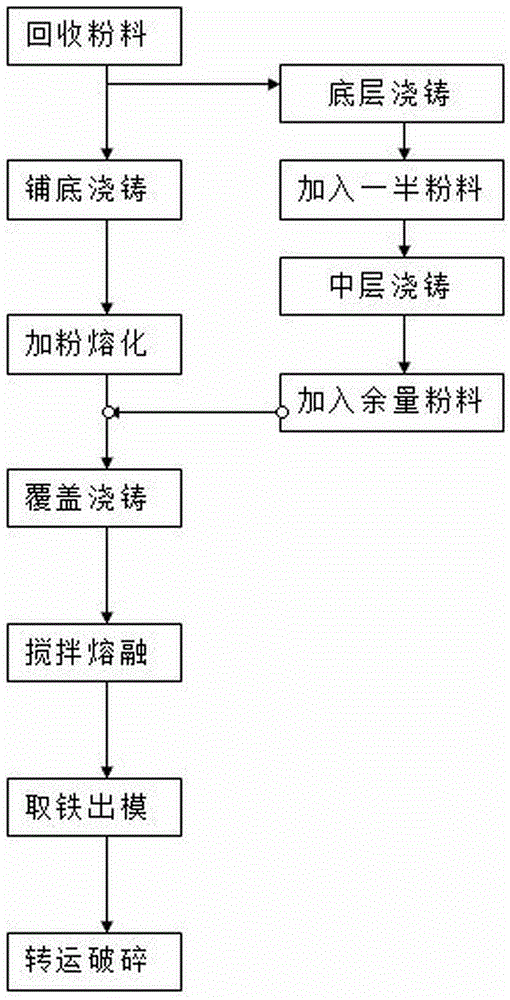

[0028] A production method of on-line molten manganese-silicon alloy powder, which is carried out in the following steps successively:

[0029] ①. Recycling powder

[0030] In the crushing workshop, the manganese-silicon alloy powder produced by crushing the manganese-silicon alloy ingot with a diagonal size of ≤10mm is collected, cleaned and concentrated for recycling, and the recovered manganese-silicon alloy powder is transferred to the smelting and casting workshop for online melting raw materials.

[0031] ②. Bottom casting

[0032] Five ingot molds are set up in the smelting and casting workshop, and 10 tons of molten manganese-silicon alloy qualified by 16500kvA electric furnace are put into the ladle in liquid state. It is estimated that each ingot mold will cast about 2 tons of manganese-silicon alloy ingot on average. The trolley moves the molten iron ladle to the top of each ingot mould, and pours 650kg of manganese-silicon alloy molten iron into each of the five ...

Embodiment 2

[0044] A production method for on-line molten manganese-silicon alloy powder, which is carried out in the manner described in Embodiment 1 after the step of "①. Recovering powder" is operated, and then proceeds according to the following steps:

[0045] ②. Bottom casting

[0046]Eight ingot molds are set up in the smelting and casting workshop, and 16 tons of molten manganese-silicon alloy smelted by a 25,000kvA electric furnace are put into the ladle in a liquid state. It is estimated that each ingot mold will cast about 2 tons of manganese-silicon alloy ingots on average. The trolley moves the molten iron ladle to the top of each ingot mold one by one, and pours 800kg of manganese-silicon alloy molten iron into the eight ingot molds one by one in turn to complete the bottom casting operation.

[0047] ③. Powder melting

[0048] Add the manganese-silicon alloy powder one by one with a steel spade into the eight ingot molds that have been bottom-cast. The weight of the mangan...

Embodiment 3

[0053] A production method for on-line molten manganese-silicon alloy powder, which is carried out in the manner described in Embodiment 1 after the step of "①. Recovering powder" is operated, and then proceeds according to the following steps:

[0054] ②. Bottom casting

[0055] Five ingot molds are set up in the smelting and casting workshop, and 10 tons of molten manganese-silicon alloy qualified by 16500kvA electric furnace is put into the ladle in a liquid state, and the trolley is operated to move the ladle to the top of each ingot mold one by one in turn. 450kg of manganese-silicon alloy molten iron is poured into each of the five ingot moulds, and the bottom casting operation is completed.

[0056] ③. Add half of the powder

[0057] Add the manganese-silicon alloy powder one by one with a steel shovel into the five ingot molds that have been cast at the bottom layer one by one. The weight of the manganese-silicon alloy powder added to each ingot mold is 80kg. Stir, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com