A molding device for optical glass and its production process

An optical glass and molding device technology, which is applied to the production of lanthanide optical glass strips with a molding thickness of more than 40mm, and the field of optical glass strip molding devices, can solve the problem that the overall quality is not improved, the glass molding quality is not improved, Increase the surface viscosity of the glass liquid and other problems to achieve the effects of accurate and stable molding temperature control, avoiding surface streaks and crystallization, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings.

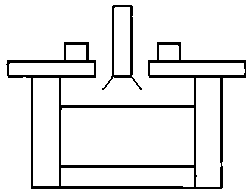

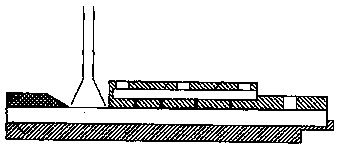

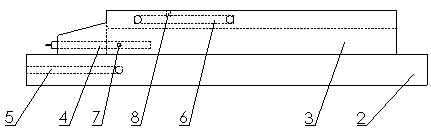

[0040] Such as image 3 , Figure 4 , Figure 7 shown. The optical glass forming device of the present invention includes a bottom mold 2 , a top mold 3 , a heating device 4 , a bottom mold cooling channel 5 , a top mold cooling channel 6 , a first temperature measuring thermocouple 7 and a second temperature measuring thermocouple 8 . Top mold 3 is 20-40mm thick, 300-600mm long U-shaped groove, bottom mold 2 is 30-80mm thick, 500-800mm long flat bottom plate, top mold 3 and bottom mold 2 are installed together to form glass molding cavity. The groove width (mold cavity width) of the U-shaped groove is 100-200mm, and the groove height is 40-80mm, which can produce optical glass strips of various diameters corresponding to the cavity size. The front end of the top mold 3 cuts out a 50-100mm long slope, which is convenient for the installation of the leakage pipe and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com