Process for smelting opal glass base material capable of preventing fluorin volatilization

A basic material, opal glass technology, used in glass furnace equipment, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of escaping outside the furnace, surrounding environmental pollution and damage, color difference, etc., to achieve accelerated liquefaction speed and stable product quality , to achieve the effect of temperature stratification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

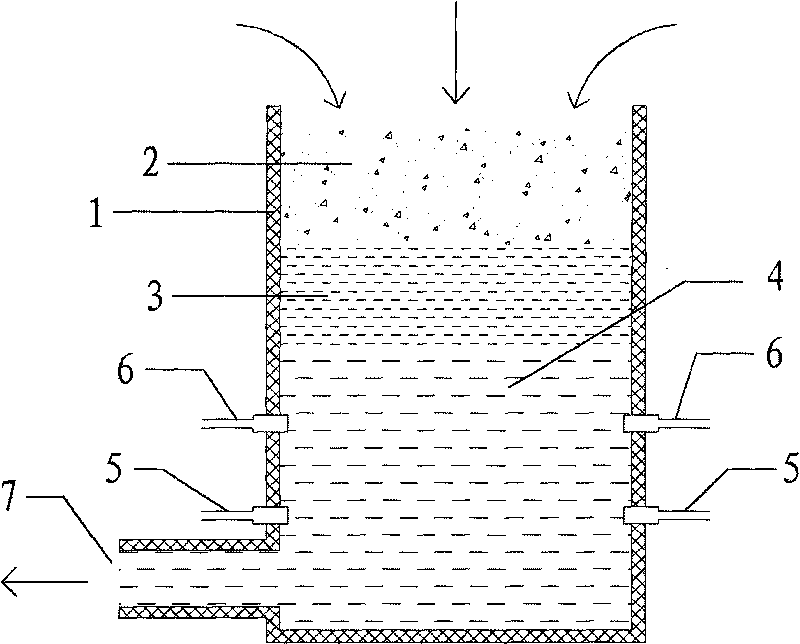

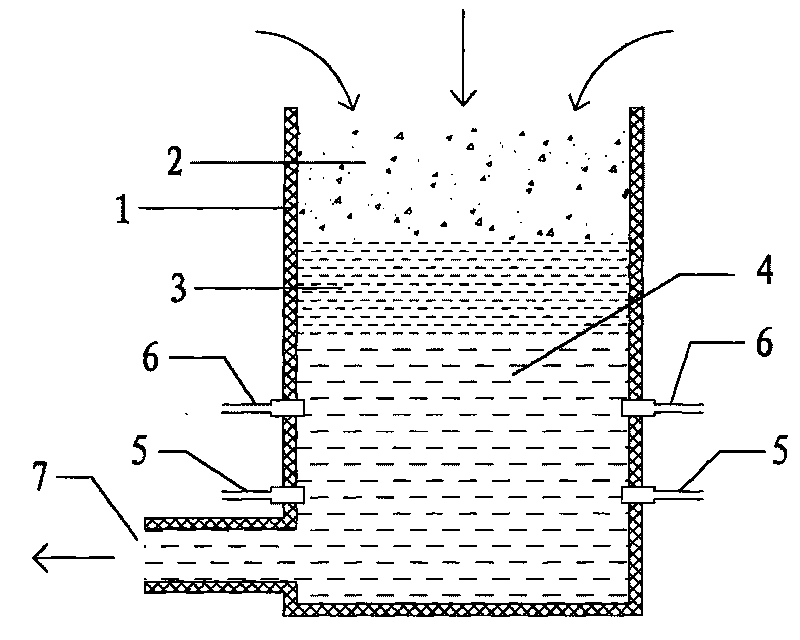

[0017] The fluorine volatilization-proof opal glass basic material smelting process of the present invention includes:

[0018] (1) Add the opal glass basic material from the top of the furnace 1 to a height of 2 meters, and then use the electrodes 5 and 6 to heat the lower and middle parts of the furnace 1 respectively, and the heating temperature of the electrode 5 to the lower material reaches 1450 °C required for smelting, The heating power of the electrode 6 is smaller than that of the electrode 5, which preheats the material; the base material in the lower part of the furnace 1 is liquefied at high temperature to form a liquefied layer 4, and the base material in the middle of the furnace 1 begins to melt to form a semi-melted layer 3, the uppermost The material is the solid layer 2, and the liquefied base material is output to the storage tank through the discharge port 7 at the bottom of the melting furnace 1 under the action of pressure and then transferred to the prod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com