Asphalt concrete additive and preparation method thereof

An asphalt concrete and additive technology, which is applied in the field of high modulus asphalt concrete additives and its preparation, can solve the problems of insufficient anti-aging performance, reducing the low-temperature performance of asphalt concrete, weakening the low-temperature performance of asphalt mixture, etc., so as to improve the anti-aging performance, The effect of improving rutting resistance and low temperature performance, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

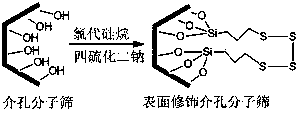

[0038] (1) 10 parts by weight of MCM-41 mesoporous molecular sieve (with a specific surface area of 1000 m 2 / g), 0.4 parts by weight of disodium tetrasulfide were added to 100 parts by weight of toluene. Heating to 50°C, adding 0.5 parts by weight of γ-chloropropyltrimethoxysilane dropwise, raising the temperature to 70°C for 2 hours, cooling, filtering, washing with ethanol, and drying at 100°C for 2 hours to obtain a surface-modified mesoporous molecular sieve.

[0039] (2) Copolymerize 100 parts by weight of high-density polyethylene (melt flow index is 2 g / 10 min), 10 parts by weight of polypropylene (melt flow index is 10 g / 10 min), and 10 parts by weight of acetic acid-vinyl acetate (melt flow index is 35 g / 10min), 4 parts by weight of surface-modified mesoporous molecular sieves, and 2 parts by weight of 2,6-di-tert-butyl-p-cresol are mixed evenly, and then blended and extruded by a twin-screw extruder and granulation to obtain asphalt concrete additive. The operat...

Embodiment 2

[0041] (1) 10 parts by weight of MCM-48 mesoporous molecular sieve (with a specific surface area of 800 m 2 / g), 0.6 parts by weight of disodium tetrasulfide were added to 150 parts by weight of xylene. Heating to 55°C, adding 0.8 parts by weight of γ-chloropropyltriethoxysilane dropwise, raising the temperature to 75°C for 2 hours, cooling, filtering, washing with ethanol, and drying at 100°C for 3 hours to obtain a surface-modified mesoporous molecular sieve.

[0042] (2) Copolymerize 100 parts by weight of high-density polyethylene (melt flow index is 8 g / 10 min), 20 parts by weight of polypropylene (melt flow index is 15 g / 10 min), and 15 parts by weight of acetic acid-vinyl acetate (melt flow index is 25 g / 10min), 5 parts by weight of surface-modified mesoporous molecular sieves, and 3 parts by weight of 4,4'-thiobis(6-tert-butyl-3-methylphenol) were mixed evenly, The asphalt concrete additive is obtained by blending, extruding and granulating through a twin-screw extr...

Embodiment 3

[0044] (1) 10 parts by weight of SBA-15 mesoporous molecular sieve (with a specific surface area of 1100 m 2 / g), 0.7 parts by weight of disodium tetrasulfide were added to 150 parts by weight of toluene. Heating to 60°C, adding 1.0 parts by weight of chloromethyltriethoxysilane dropwise, raising the temperature to 75°C for 3 hours, cooling, filtering, washing with ethanol, and drying at 100°C for 5 hours to obtain a surface-modified mesoporous molecular sieve.

[0045] (2) Copolymerize 100 parts by weight of high-density polyethylene (melt flow index is 15 g / 10 min), 30 parts by weight of polypropylene (melt flow index is 10 g / 10 min), and 20 parts by weight of acetic acid-vinyl acetate (melt flow index is 15 g / 10min), 6 parts by weight of surface-modified mesoporous molecular sieves, 4 parts by weight of β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate isooctyl ester After uniformity, blending, extrusion and granulation by a twin-screw extruder to obtain the asphalt concr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

| Melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com