Modified phenolic resin as well as preparation method and application thereof

A phenolic resin and modification technology, which is applied in the field of modified phenolic resin and its preparation, can solve problems such as limiting the application of phenolic resin, affecting resin performance, and VOC volatilization, so as to improve flexibility, increase paint film thickness, and reduce brittleness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

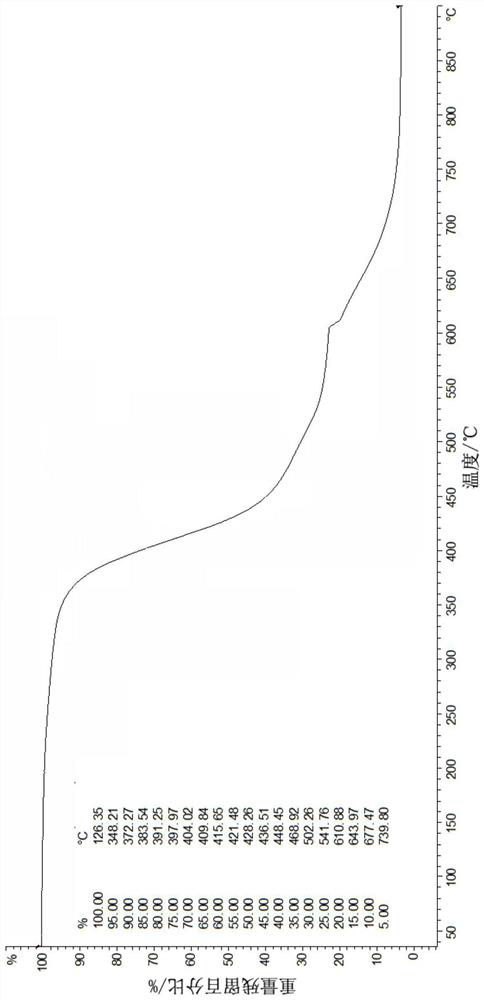

Image

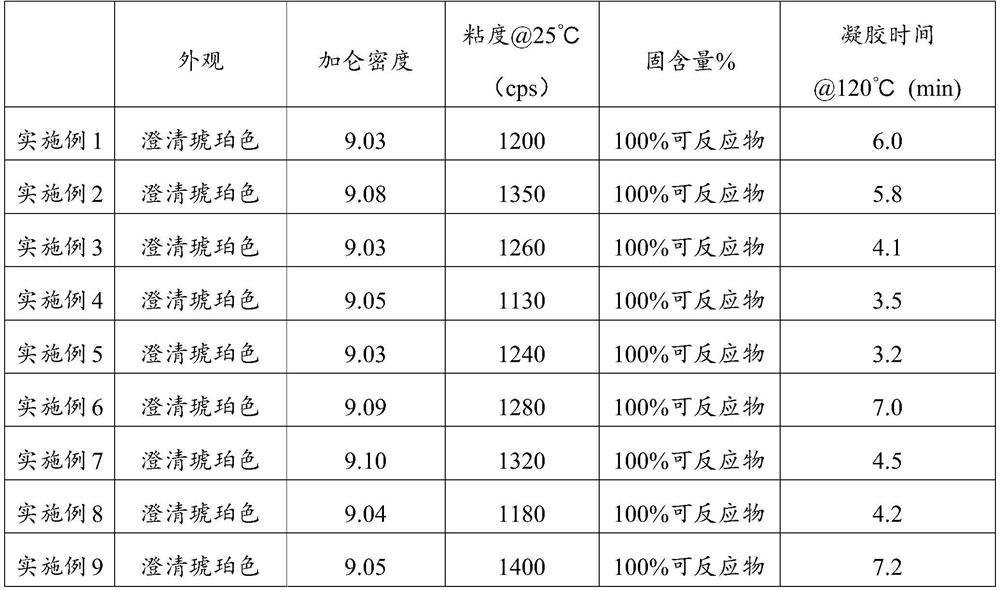

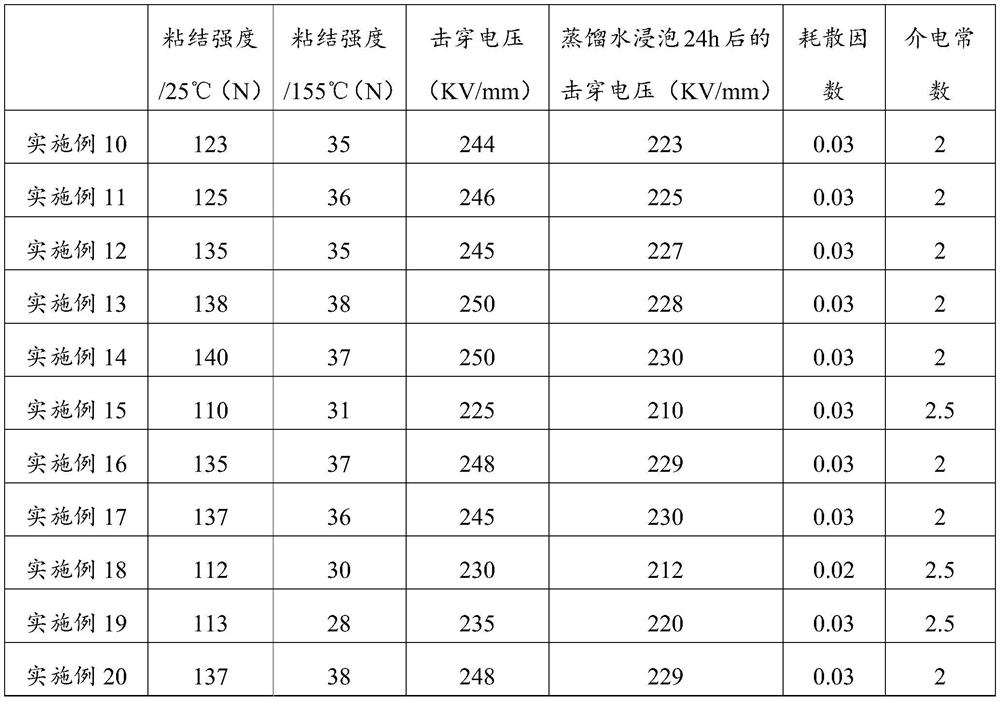

Examples

Embodiment 1

[0042] A preparation method of modified phenolic resin, comprising the following steps:

[0043] In parts by weight, take 100 parts of phenol, 6.2 parts of paraformaldehyde, 7 parts of boric acid, and 23 parts of hydroxyethyl acrylate and add them to the first reaction kettle, start stirring, and after stirring evenly, heat up to 150°C for condensation reaction; test the reaction until the viscosity reaches 10.0-15.0poise (BROOKFIELD viscometer 5# rotor, the test temperature is 80 ℃), stop the reaction, and prepare the modified phenolic resin.

Embodiment 2

[0045] A preparation method of modified phenolic resin, comprising the following steps:

[0046] In parts by weight, take 100 parts of phenol, 8.5 parts of paraformaldehyde, 8 parts of boric acid, and 26 parts of hydroxyethyl acrylate and add them to the first reaction kettle, start stirring, and after stirring evenly, heat up to 150°C for condensation reaction; test reaction until the viscosity reaches 10.0-15.0poise (BROOKFIELD viscometer 5# rotor, the test temperature is 80 ℃), stop the reaction, and prepare the modified phenolic resin.

Embodiment 3

[0048] A preparation method of modified phenolic resin, comprising the following steps:

[0049] In parts by weight, take 100 parts of p-tert-butylphenol, 75 parts of furfural, 23 parts of tributyl borate, and 28 parts of hydroxypropyl methacrylate into the first reaction kettle, start stirring, and after stirring evenly, heat up to 150 Condensation reaction at ℃; test the viscosity of the reactant until the viscosity reaches 10.0-15.0poise (BROOKFIELD viscometer 5# rotor, the test temperature is 80 ℃), stop the reaction, and obtain the modified phenolic resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com