Slate ceramic tile with diamond gloss effect and preparation method thereof

A technology of ceramic tiles and diamonds, which is applied in the field of ceramic tiles, can solve the problems affecting the decoration effect of ceramic tile surface patterns, etc., and achieve the effect of improving chemical stability, obvious effect and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

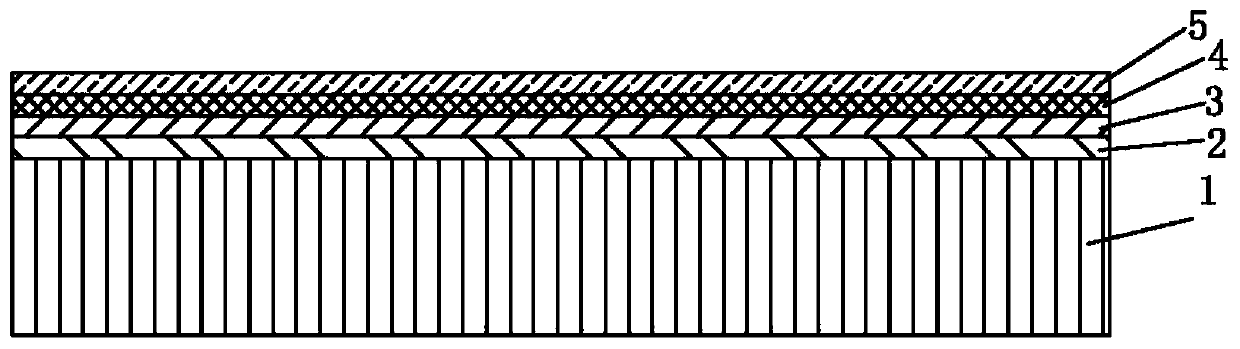

[0033] like figure 1 As shown, a slate ceramic tile with a diamond luster effect includes a green brick 1, a bottom glaze layer 2, a pattern layer 3, a transparent glaze layer 4 and a diamond flashing dry grain glaze layer 5 sequentially compounded from bottom to top.

[0034] A kind of preparation method of the above-mentioned slate ceramic brick with diamond luster effect, comprises the steps:

[0035] (1) The blank is pressed into the green brick 1, and dried in a roller kiln;

[0036] (2) applying primer on the surface of the embryo brick 1;

[0037] (3) printing a slate-like pattern on the surface of the bottom glaze by 3D printing to form a pattern layer 3;

[0038] (4) apply transparent glaze on the surface of the pattern layer 3;

[0039] (5) On the surface of the transparent glaze, the diamond flashing dry grain glaze is applied, and the diamond dry grain glaze comprises the raw materials of the following parts by weight: 65 parts of methyl water, 15 parts of dry gra...

Embodiment 2

[0050] like figure 1 As shown, a slate ceramic tile with a diamond luster effect includes a green brick 1, a bottom glaze layer 2, a pattern layer 3, a transparent glaze layer 4 and a diamond flashing dry grain glaze layer 5 sequentially compounded from bottom to top.

[0051] A kind of preparation method of the above-mentioned slate ceramic brick with diamond luster effect, comprises the steps:

[0052] (1) The blank is pressed into the green brick 1, and dried in a roller kiln;

[0053] (2) applying primer on the surface of the embryo brick 1;

[0054] (3) printing a slate-like pattern on the surface of the bottom glaze by 3D printing to form a pattern layer 3;

[0055] (4) apply transparent glaze on the surface of the pattern layer 3;

[0056] (5) On the surface of the transparent glaze, the diamond glitter dry grain glaze is applied, and the diamond dry grain glaze includes the raw materials of the following parts by weight: 60 parts of methyl water, 10 parts of dry gra...

Embodiment 3

[0065] like figure 1 As shown, a slate ceramic tile with a diamond luster effect includes a green brick 1, a bottom glaze layer 2, a pattern layer 3, a transparent glaze layer 4 and a diamond flashing dry grain glaze layer 5 sequentially compounded from bottom to top.

[0066] A kind of preparation method of the above-mentioned slate ceramic brick with diamond luster effect, comprises the steps:

[0067] (1) The blank is pressed into the green brick 1, and dried in a roller kiln;

[0068] (2) applying primer on the surface of the embryo brick 1;

[0069] (3) printing a slate-like pattern on the surface of the bottom glaze by 3D printing to form a pattern layer 3;

[0070] (4) apply transparent glaze on the surface of the pattern layer 3;

[0071] (5) On the surface of the transparent glaze, the diamond flashing dry grain glaze is applied, and the diamond dry grain glaze includes the raw materials of the following parts by weight: 70 parts of methyl water, 20 parts of dry gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com