Electromagnetic shielding material preparation method, electromagnetic shielding material product and electromagnetic shielding key terminal

An electromagnetic shielding material, electromagnetic shielding technology, applied in the fields of magnetic/electric field shielding, circuits, electrical components, etc., can solve the problems of inconvenient use of keys, reduced shielding effectiveness, electromagnetic leakage, etc., to achieve superior performance, reduce electromagnetic leakage, toughness good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A preparation method of electromagnetic shielding material includes the following steps:

[0026] 1) Prepare the following components in parts by weight ratio:

[0027]

[0028] Wherein, the silicone rubber is methyl vinyl silicone rubber; the curing agent is trimethyl hexamethylene diamine; and the heat stabilizer is epoxy fatty acid methyl ester.

[0029] 2) After heating and melting the silicone rubber and polytetrafluoroethylene, add nanometer graphite powder and stir under high-speed stirring for 10-20 minutes to make it uniformly mixed and dispersed; then add curing agent and heat stabilizer, and stir the same , Make it uniformly dispersed to form a molten composite rubber mixture uniformly infiltrated with nanometer graphite particles.

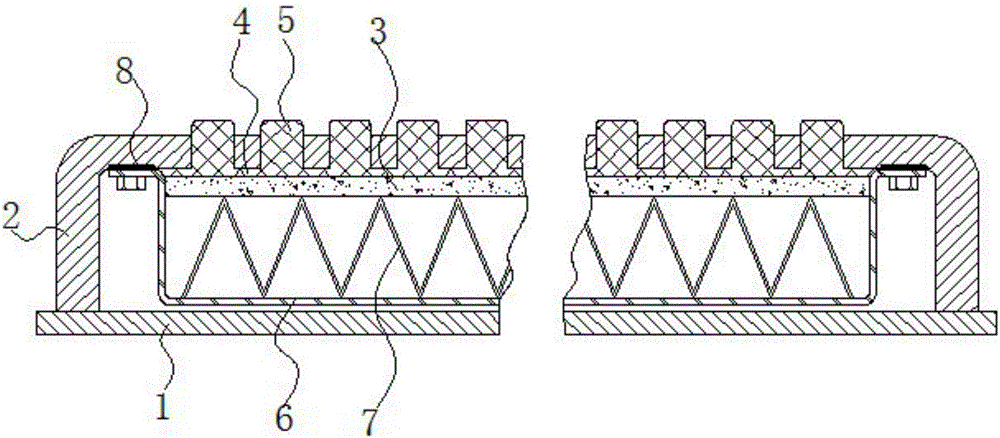

[0030] 3) Preparing the forming mold (generally including a fixed mold. The fixed mold is equipped with a mold cavity. The corresponding mold cavity has a movable mold. The movable mold has a certain squeezing effect on the material in t...

Embodiment 2

[0038] Embodiment 2 is basically the same as embodiment 1, and the difference lies in:

[0039] A preparation method of electromagnetic shielding material includes the following steps:

[0040] 1) Prepare the following components in parts by weight ratio:

[0041]

[0042] Wherein, the silicone rubber is methyl vinyl silicone rubber; the curing agent is trimethyl hexamethylene diamine; and the heat stabilizer is epoxy fatty acid methyl ester.

[0043] 2) After heating and melting the silicone rubber and polytetrafluoroethylene, add nanometer graphite powder and stir for 10 minutes under high-speed stirring to make it uniformly mixed and dispersed; then add curing agent and heat stabilizer, and stir the same to make It is uniformly dispersed to form a molten composite rubber mixture uniformly infiltrated with nanometer graphite particles.

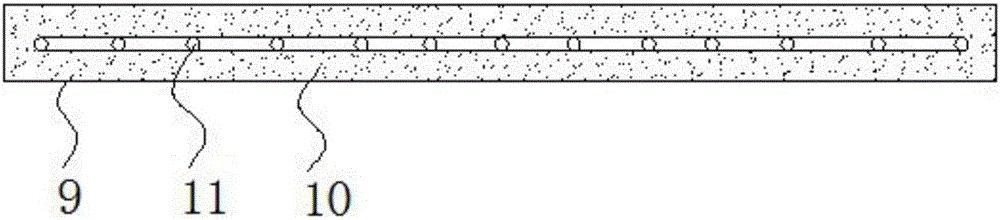

[0044] 3) Prepare a forming mold, and place a wire mesh made of metal wires crisscrossed in the cavity of the forming mold; inject the compound rubb...

Embodiment 3

[0049] Embodiment 3 is basically the same as embodiment 1, and the difference lies in:

[0050] A preparation method of electromagnetic shielding material includes the following steps:

[0051] 1) Prepare the following components in parts by weight ratio:

[0052]

[0053] Wherein, the silicone rubber is methyl vinyl silicone rubber; the curing agent is trimethyl hexamethylene diamine; and the heat stabilizer is epoxy fatty acid methyl ester.

[0054] 2) After heating and melting the silicone rubber and polytetrafluoroethylene, add nanometer graphite powder and stir under high-speed stirring for 10-20 minutes to make it uniformly mixed and dispersed; then add curing agent and heat stabilizer, and stir the same , Make it uniformly dispersed to form a molten composite rubber mixture uniformly infiltrated with nanometer graphite particles.

[0055] 3) Prepare a forming mold, and place a wire mesh made of metal wires crisscrossed in the cavity of the forming mold; inject the compound rubbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com