Aging-resistant and corrosion-resistant SMC sheet molding compound and molding device thereof

A sheet molding compound and molding device technology, applied in the field of SMC sheet molding compound preparation, can solve the problems of affecting product processing quality, easy aging, leaving top marks, etc., to achieve rapid cooling and solidification, and enhance aging resistance , Improve the effect of corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

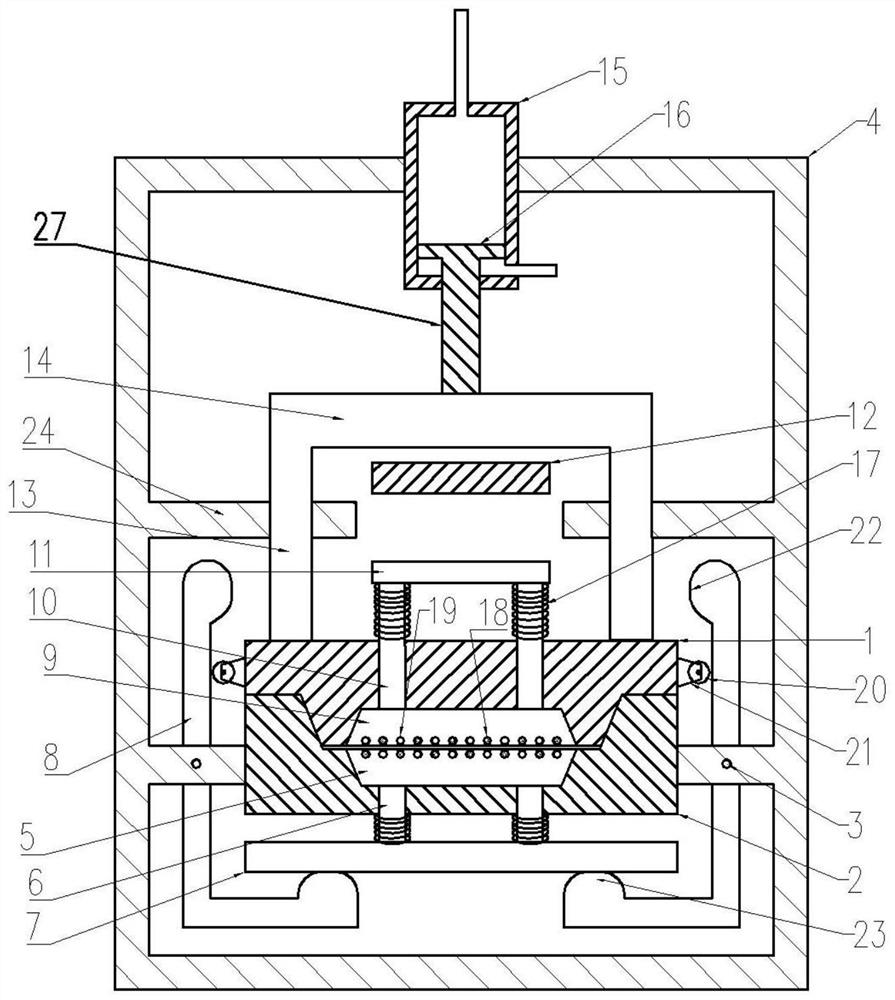

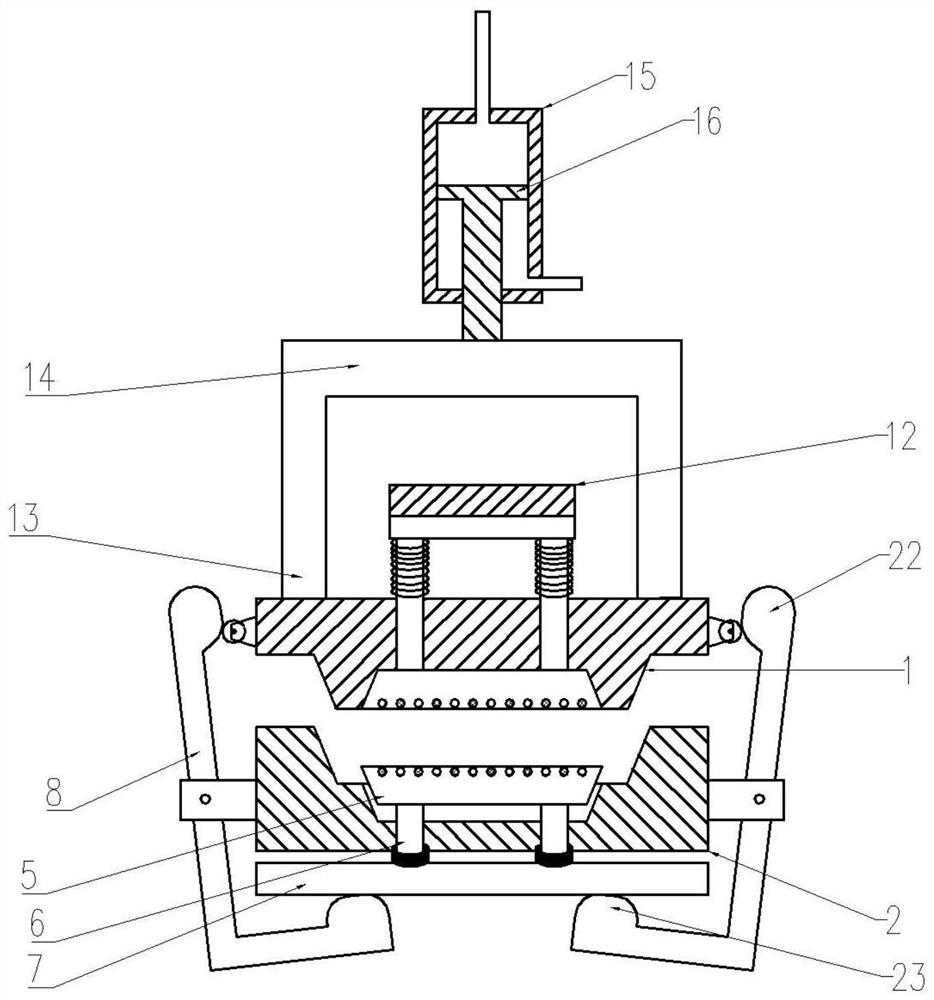

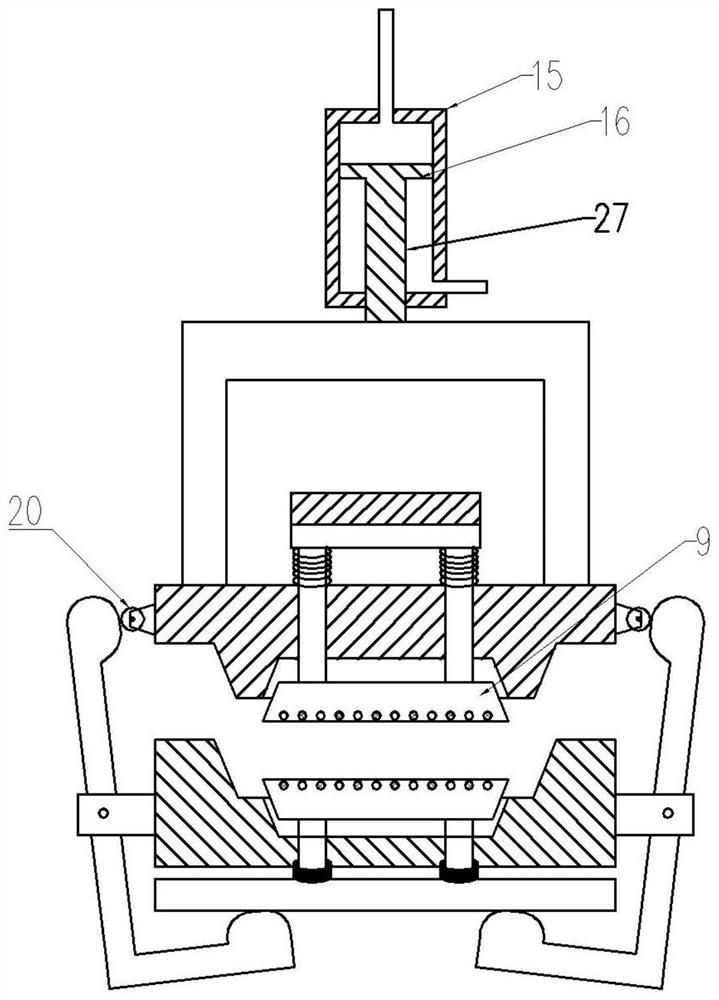

[0029] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals.

[0030] It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

[0031] An aging-resistant and corrosion-resistant SMC sheet molding compound: its raw materials include, by weight, 70-120 parts of epoxy vinyl ester resin; 2-4 parts of antioxidant; 8-12 parts of toughening agent; low-profile agent 15-30 parts; 1-5 parts of thickener; 30-50 parts of 15-25mm non-alkali untwisted glass fiber; 8-12 parts of release agent; 1-4 parts of curing agent; 5-10 parts of color paste; dispersion 2 to 2.5 parts of active magnesium oxide; 0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com