Shaping device of fluorophosphate optical glass and its shaping method

An optical glass, fluorophosphate technology, applied in glass forming, glass pressing, glass manufacturing equipment and other directions, can solve the problems of high temperature glass liquid component volatilization, fluorophosphate glass corrosion, deep stripes on the product surface, etc. Avoid corrosion of molds and ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

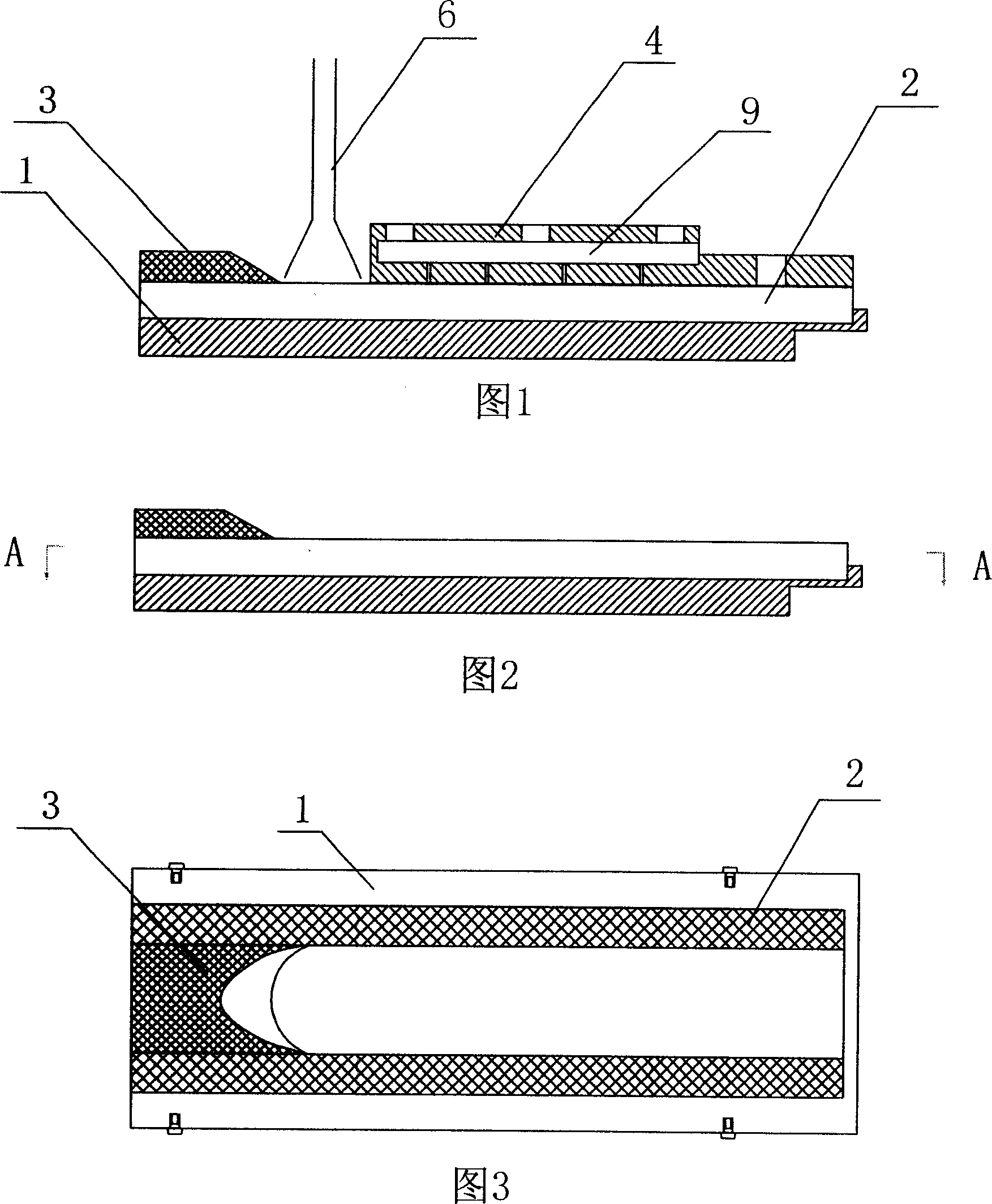

[0015] As shown in Figure 1, the molding device of the present invention is made up of molding die and cooling cover plate 4, and cooling cover plate 4 is covered on the molding die, and wherein molding die is made of bottom mold 1, side mold 2 and stopper 3, in cooling Vent holes are provided on the cover plate 4 .

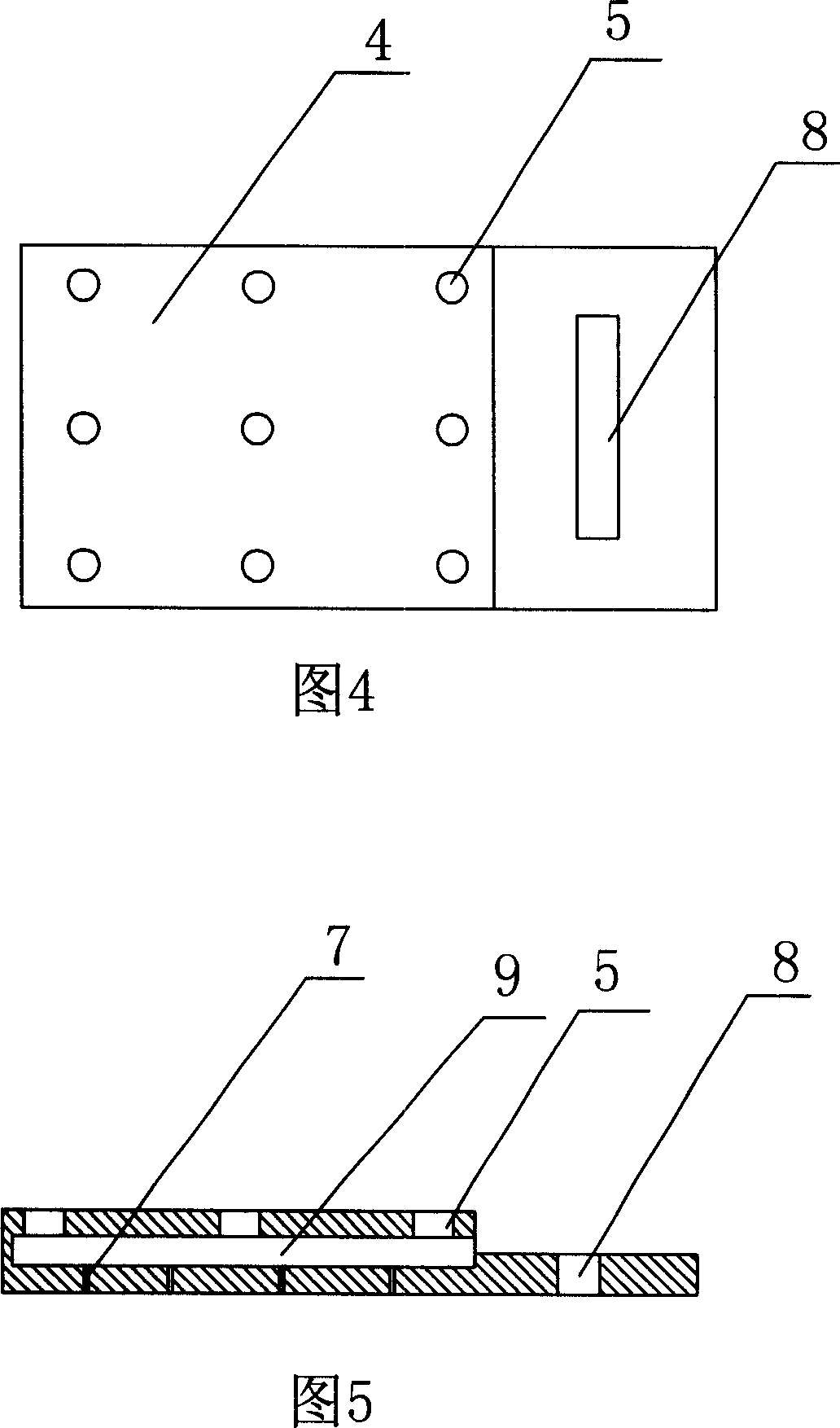

[0016] The ventilation hole on the cooling cover plate 4 can be set as shown in Figure 1, Figure 4 and Figure 5, the upper surface of the cooling cover plate 4 is provided with an air inlet 5, and the lower surface is provided with some pinhole-shaped air outlet holes 7, cooling The middle of the cover plate 4 is a cavity 9 through which the air inlet hole 5 and the air outlet hole 7 communicate. After the inert gas enters the cavity 9 through the inlet hole 5 on the upper surface, it is blown out through the outlet hole 7 on the lower surface.

[0017] The above-mentioned gas outlet holes 7 are arranged as several pinhole-shaped small holes, which can ensure th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com