Slurry filtration system used for power lithium ion battery of HEV/PHEV

A lithium-ion battery and filtration system technology, applied in the direction of filtration separation, filtration circuit, separation method, etc., can solve the problems of a large number of scratches or streaks on the coating surface, particle size that cannot meet the requirements, and is not suitable for filtration, etc., to avoid coating Scratches or streaks on the coated surface, easy to scale production, and avoid clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

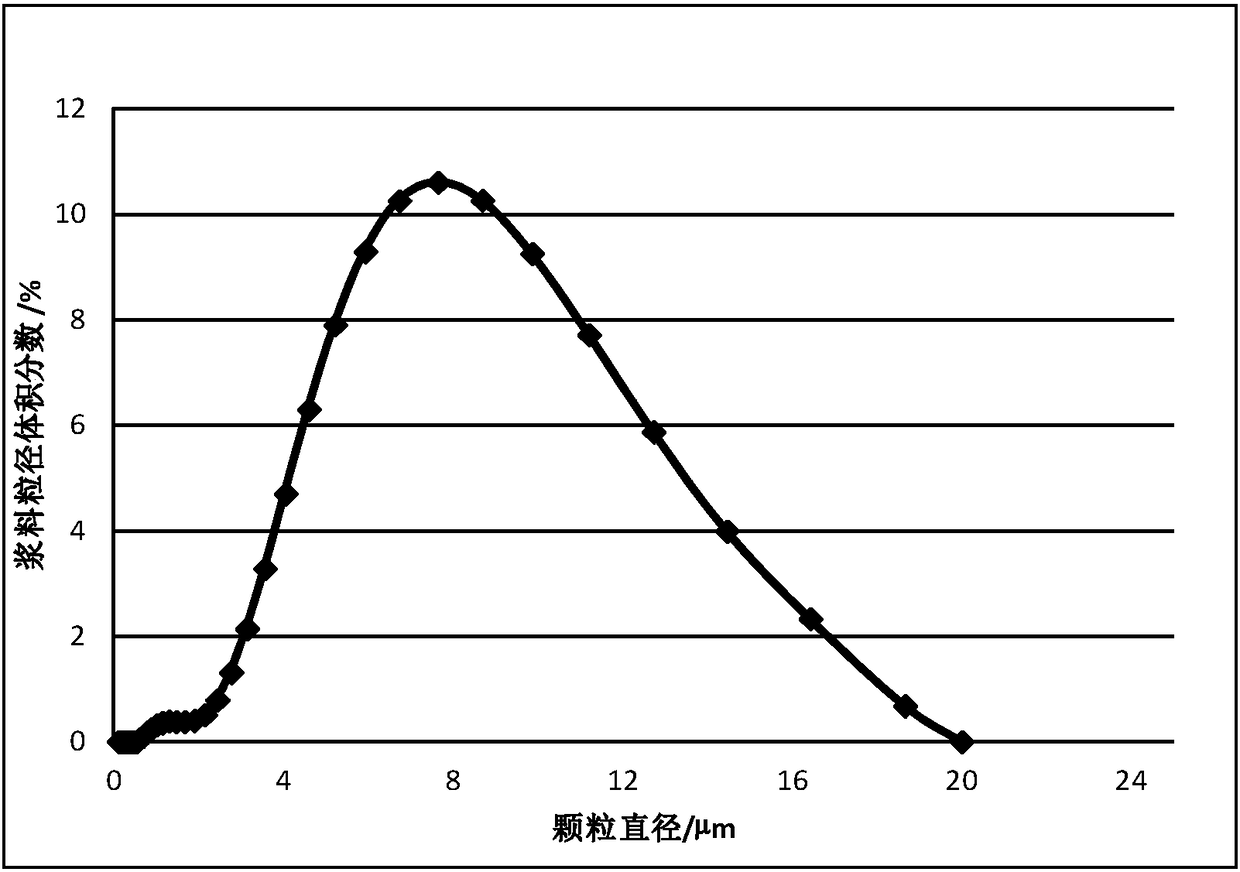

[0026] A slurry filtration system for power lithium-ion batteries of HEV / PHEV, such as the slurry filtration system used to filter the slurry required for the negative electrode sheet in the power ion battery of PHEV, differs from Example 1 in that the ultrasonic The power is 23 KHz, the output power is 7 KW, the ultrasonic time is 22 min, and the interval time is 160 min. The particle size distribution of the filtered slurry is: D10≤5 µm, D50≤6.7 µm, D90≤13.0 µm, and The particle size of the 10% volume slurry is 13.0-19.8 µm, fully meeting the application requirements.

Embodiment 3

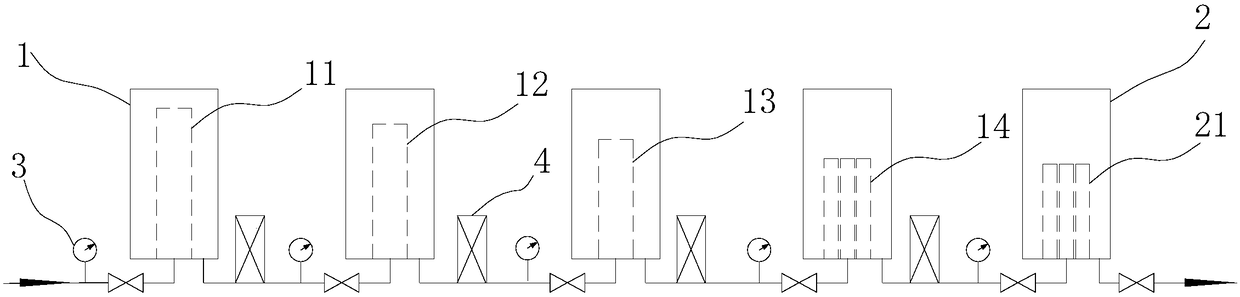

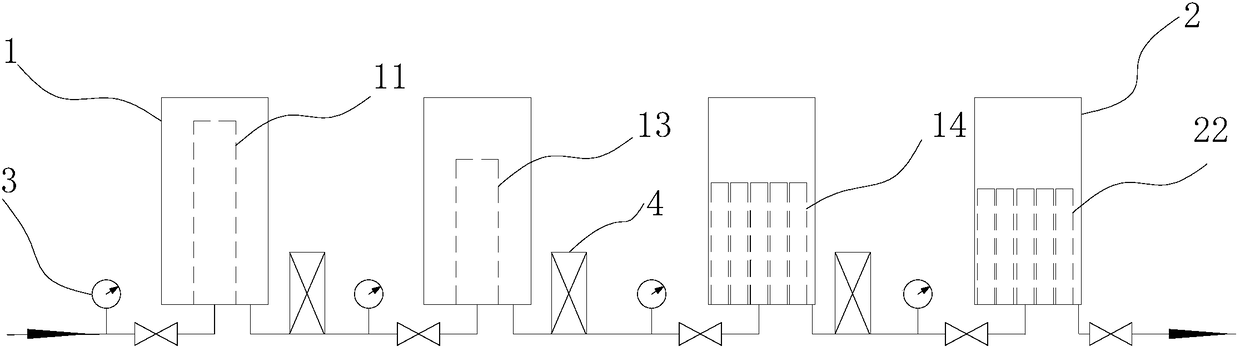

[0028] A slurry filtration system for HEV / PHEV power lithium-ion batteries, such as a slurry filtration system for filtering the slurry required for the positive electrode sheet of HEV power ion batteries, wherein the particle size volume distribution of the original slurry is: D10≤ 7 µm, D50≤14 µm, D90≤25 µm, the particle size of the remaining 10% of the volume of the slurry is 25 µm to 35 µm, and the maximum particle size is 35 µm, because the thickness of the negative electrode sheet is required to be a single layer of 30 µm, so it is required The maximum particle size after filtration should not exceed 30 µm. Such as image 3As shown, the slurry system includes a slurry flow pipeline, in which there are three filters 1 connected in series in order of filter pore size from large to small, wherein the first filter is equipped with a 180 µm sieve 11. There is a 75 µm sieve in the second filter 13, five 48 µm sieves in parallel in the third filter, and a depth filter group co...

Embodiment 4

[0030] A slurry filtration system for a HEV / PHEV power lithium ion battery, such as a slurry filtration system for filtering the slurry required for the positive electrode sheet of a PHEV power ion battery, differs from Example 3 in that the power of the ultrasonic It is 30 KHz, the output power is 12 KW, the ultrasonic time is 25 min, and the interval time is 180 min. The particle size volume distribution of the filtered slurry is: D10≤5.5 µm, D50≤9.2 µm, D90≤17.0 µm, and the remaining The particle size of the 10% slurry by volume is 17.0 µm to 28.4 µm, fully meeting the application requirements.

[0031] The HEV / PHEV power lithium ion battery slurry filtering system of the present invention can effectively solve the existence of large particles in the slurry, avoid blocking the filter screen during filtering, affect the normal production of lithium ion battery slurry, and improve production efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Filter pore size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com