Novel filter assembly

A filter and assembly technology, applied in the installation/connection of lubricant purification devices, lubricating parts, pressure lubricants, etc., can solve the problem of small effective area of filter screen, low rigidity of filter screen 3, and poor quality of oil filtration and other problems to achieve the effect of avoiding the rotation and dropping of the filter screen, simple manufacturing process and increasing the filtering capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will now be described with reference to the drawings, wherein like reference numerals designate like or similar devices throughout.

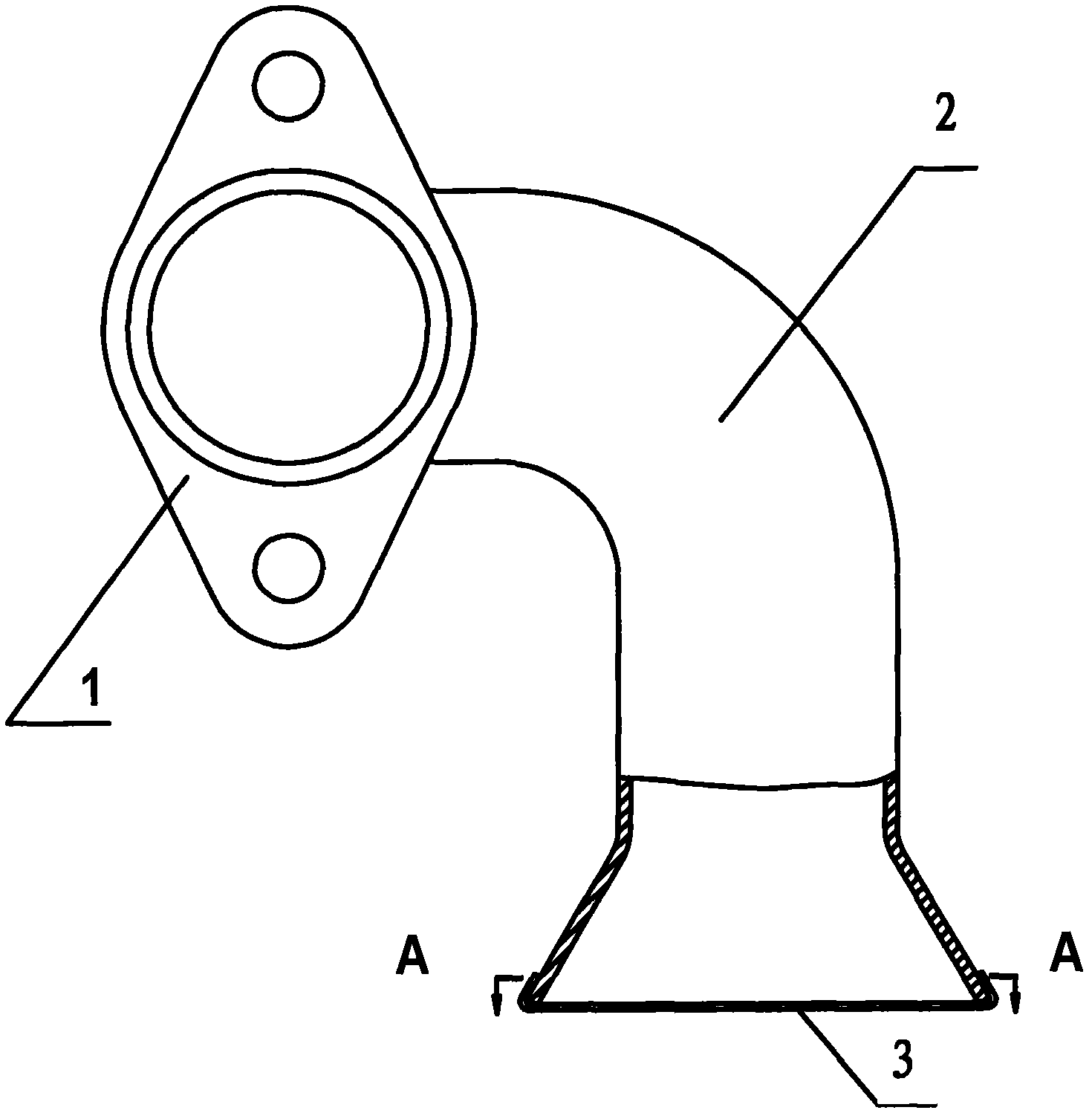

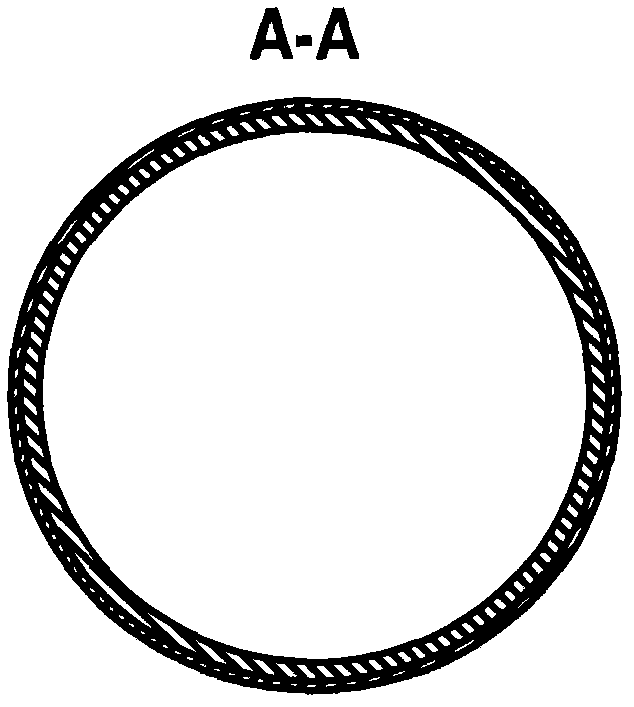

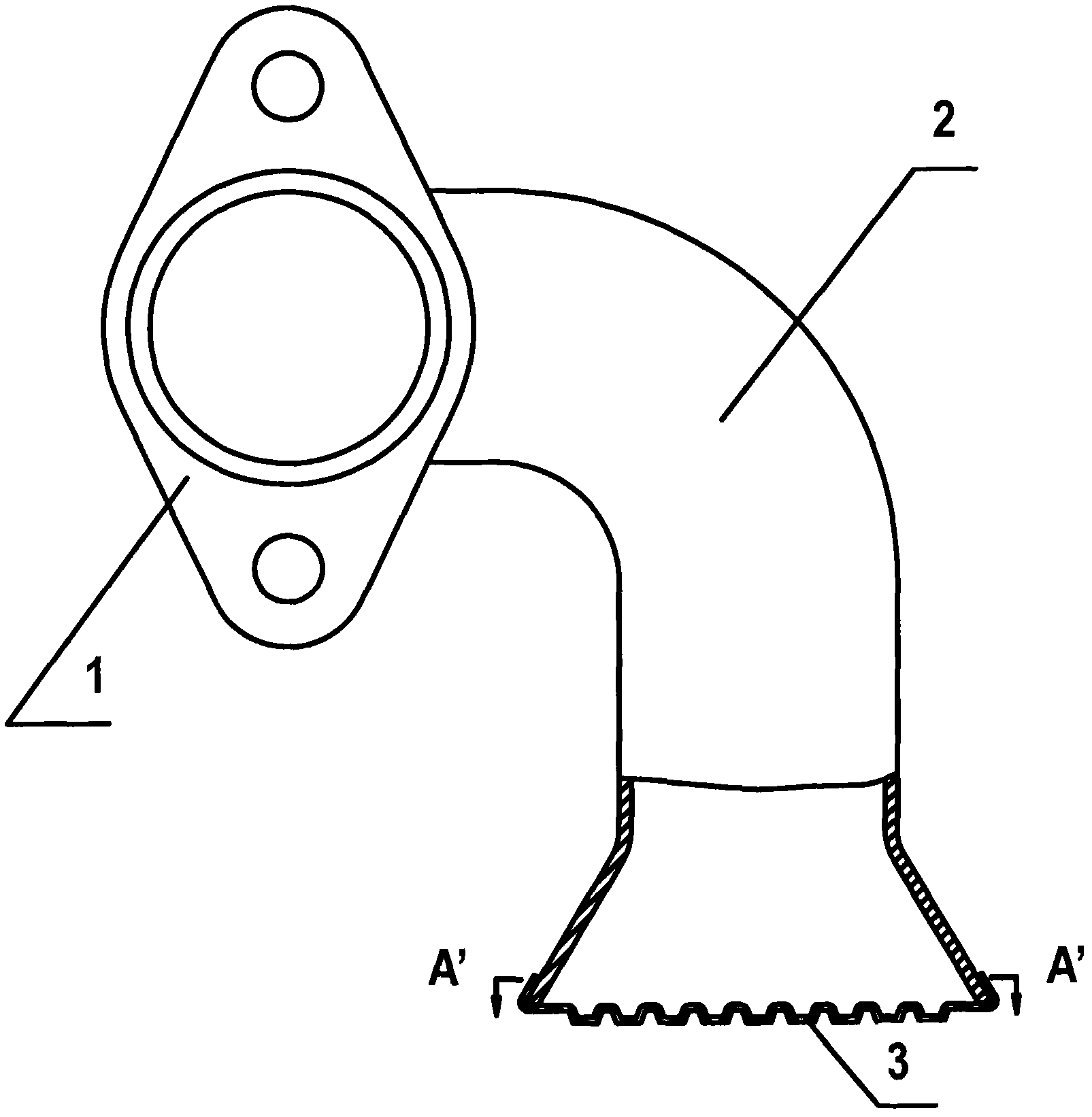

[0020] image 3 is a schematic diagram of the structure of the filter assembly according to the present invention. and figure 1 The prior art strainer assembly shown is similar, image 3 The shown filter collector assembly of the present invention also includes a flange 1 , an oil pipe 2 and a filter screen 3 pressed together with the oil pipe.

[0021] and figure 1 The prior art filter assembly shown is different in that, image 3 The shape of the press joint between the oil pipe 2 and the filter screen 3 included in the filter collector assembly of the present invention shown is non-circular, thereby limiting the degree of freedom of rotation of the filter screen 3 relative to the oil pipe 2 .

[0022] According to an embodiment of the present invention, the non-circular shape is an ellipse, such as Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com