Dry-process alkali refining agent of edible oil and preparation and use methods for dry-process alkali refining agent

A technology of edible oil and oil dry method, applied in the direction of edible oil/fat, fat oil/fat refining, application, etc., can solve the problems of high water content of edible oil, environmental pollution, complicated operation, etc., achieve strong adsorption capacity and market prospect Good, analyze and demonstrate the effect of science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a kind of dry alkali refining agent for edible oil, which is prepared from the following raw materials: silica filter aid is 55.0%; Al 2 o 3 15.0%%; Fe 2 o 3 2.0% and 5.5% of water-soluble base.

Embodiment 2

[0047] This embodiment provides a kind of dry alkali refining agent for edible oil, which is prepared from the following raw materials: perlite filter aid is 65.0%; Al 2 o 3 20.0%; Fe 2 o 3 It is 1.0% and water-soluble alkali (food alkali) 8.5%. The edible alkali is a mixture of sodium carbonate and sodium bicarbonate.

Embodiment 3

[0049] This embodiment provides a kind of dry alkali refining agent for edible oil, which is prepared from the following raw materials: perlite filter aid is 60%; Al 2 o 3 18.0%; Fe 2 o 3 1.5% and 6.5% edible alkali. The edible alkali is a mixture of sodium carbonate and sodium bicarbonate with a weight ratio of 1:3.

[0050] Preparation method, described method comprises the following steps:

[0051] (1) modifying the perlite filter aid to form a modified silica filter aid;

[0052] (2) Compounding: Al 2 o 3 , Fe 2 o 3 and water-soluble alkali are sequentially added to the modified silicon dioxide filter aid obtained in step (1) and mixed to obtain the edible oil dry alkali refining agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

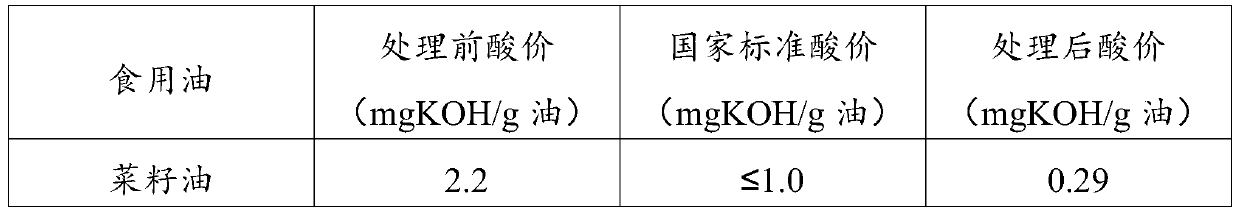

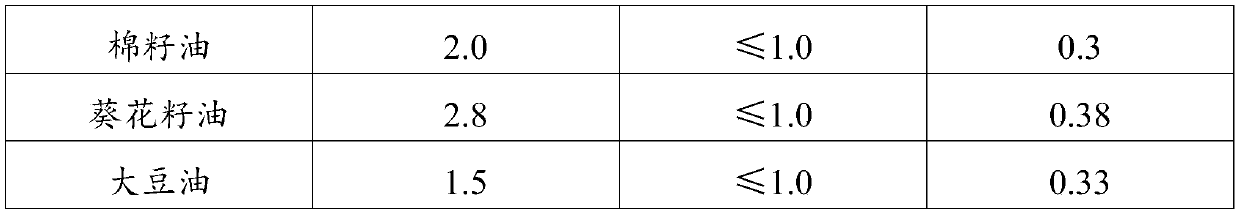

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com