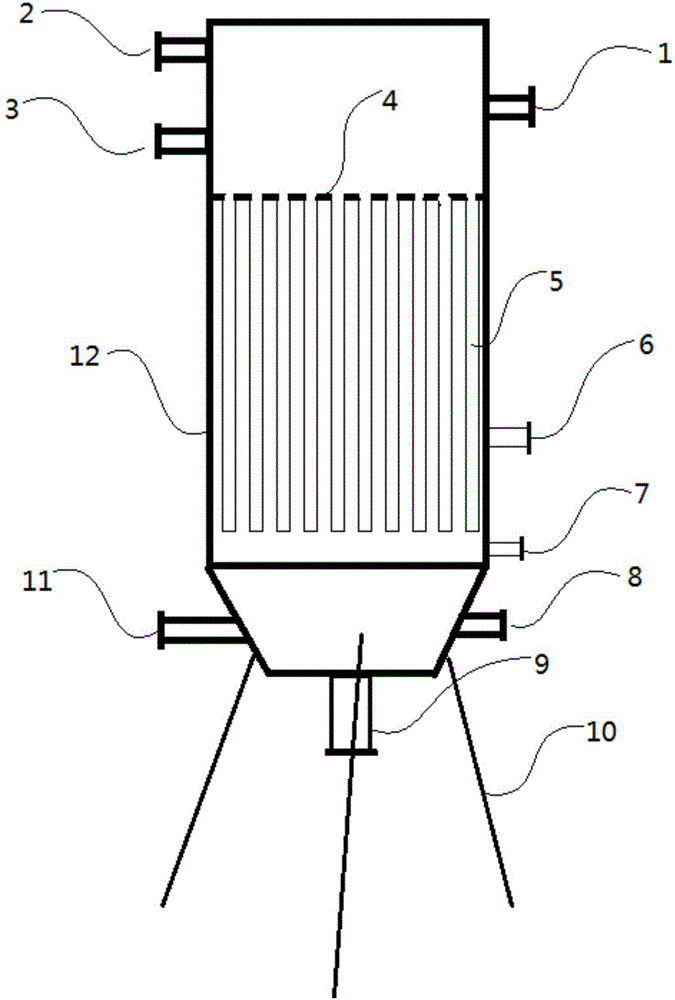

Ammonium phosphate slurry filtering device and cleaning method thereof

A filter device and ammonium phosphate technology, applied in the direction of filter separation, separation method, chemical instrument and method, etc., can solve the problems of low filtration capacity, shortened service life of filter device, difficulty in restoring the filtration capacity of filter device, etc., and achieve the filtering effect High efficiency, extended equipment life, low operating and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for cleaning an ammonium phosphate slurry filter device. The ammonium phosphate slurry with a pH value of 3, a temperature of 70°C, a solid content of 1%, and a specific gravity of ammonium phosphate of 1 has a filtration capacity of at least 25m 3 / h treatment, after the device has been running continuously for 20 hours, soak the filter bag in a sodium hydroxide solution with a temperature of 60°C and a mass concentration of 10% for 20 minutes. The soaking is treated with aeration during the soaking process. The aeration treatment is to pass the compressed air with a pressure of 0.15MPa.

Embodiment 2

[0028] A method for cleaning an ammonium phosphate slurry filter device, the ammonium phosphate slurry with a pH value of 5, a temperature of 90°C, a solid content of 2%, and a specific gravity of ammonium phosphate of 1.3 has a filtration capacity of at least 35m 3 / h treatment, after the device runs continuously for 25 hours, soak the filter bag in a sodium hydroxide solution with a temperature of 80°C and a mass concentration of 20% for 35 minutes. The soaking is treated with aeration during the soaking process. The aeration treatment is to introduce compressed air with a pressure of 0.35MPa.

Embodiment 3

[0030] A method for cleaning an ammonium phosphate slurry filter device. The ammonium phosphate slurry with a pH value of 4, a temperature of 80°C, a solid content of 1.5%, and a specific gravity of ammonium phosphate of 1.2 has a filtration capacity of at least 30m 3 / h treatment, after the device runs continuously for 23 hours, soak the filter bag in a sodium hydroxide solution with a temperature of 70°C and a mass concentration of 15% for 27 minutes. The soaking is treated with aeration during the soaking process. The aeration treatment is conducted with compressed air at a pressure of 0.2 MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com