Water filtration device and method of its manufacture

A technology of water filtration and filtration membrane, applied in chemical instruments and methods, ultrafiltration, osmotic/dialysis water/sewage treatment, etc. Improved filtration performance, effectiveness and improved usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

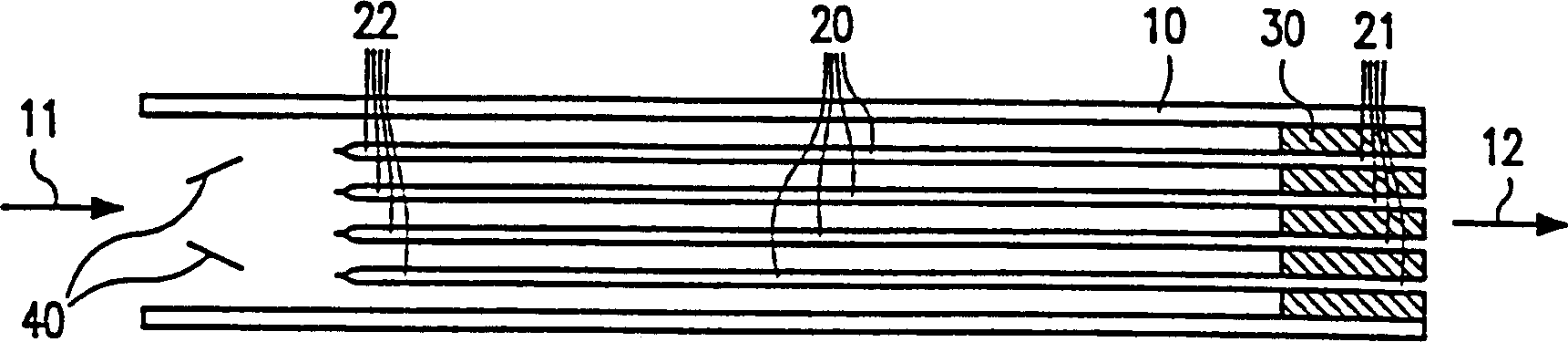

[0015] The filter housing is indicated by reference 10 in the figures. The filter housing 10 is provided with an inlet connection 11 and an outlet connection 12 . A group of capillary filter membranes 20 are arranged in the filter housing 10 , and the first ends 21 of which are embedded in the membrane holder 30 . At a first end 21 the capillary membrane is open and at the other end 22 the capillary membrane is closed. The filter housing 10 can be made of a hard material such as polysulphone, PVC or metal, but can also be made of a flexible material. In the latter case, the water filter device can be used in a bent state. In the illustrated embodiment, filter housing 10 comprises a cylindrical element.

[0016] In the illustrated embodiment, the first end 21 of the membrane 20 is embedded in a resin, such as epoxy or polyurethane, which acts as the membrane holder 30 . At the other end 22, the capillary membrane 20 is closed by heat sealing, ie heating while clamping. Thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com