Polishing mechanism used for shaft

A technique for polishing mechanisms and shafts, which is applied in the direction of grinding/polishing equipment, grinding workpiece supports, grinding machines, etc. It can solve problems such as uneven polishing and abrasive belt polishing marks, and achieve strip-shaped grinding marks, uniform grinding, and Better polishing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below by means of specific embodiments:

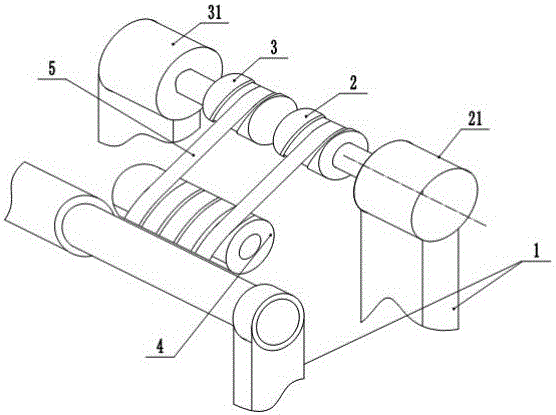

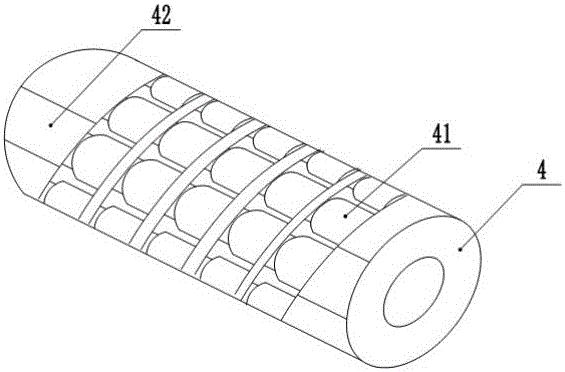

[0016] The reference signs in the drawings of the description include: frame 1, first driving roller 2, first motor 21, second driving roller 3, second motor 31, driving roller 4, roller 41, end plane 42, abrasive belt 5 .

[0017] The embodiment is basically as attached figure 1 And attached figure 2 Shown:

[0018] A polishing mechanism for a shaft, mainly composed of a clamping device, a frame 1, an abrasive belt 5, a driving roller 4, a first driving roller 2 and a second driving roller 3, the clamping device and the driving roller are installed on the frame 1 Above, the clamping device is composed of a three-jaw chuck for clamping the shaft parts and a support plate for clamping the end of the shaft parts, and the support plate is rotatably connected to the frame 1 . The transmission roller 4 is fixedly connected on the frame 1, and the transmission roller 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com