Patents

Literature

221results about How to "Reuse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

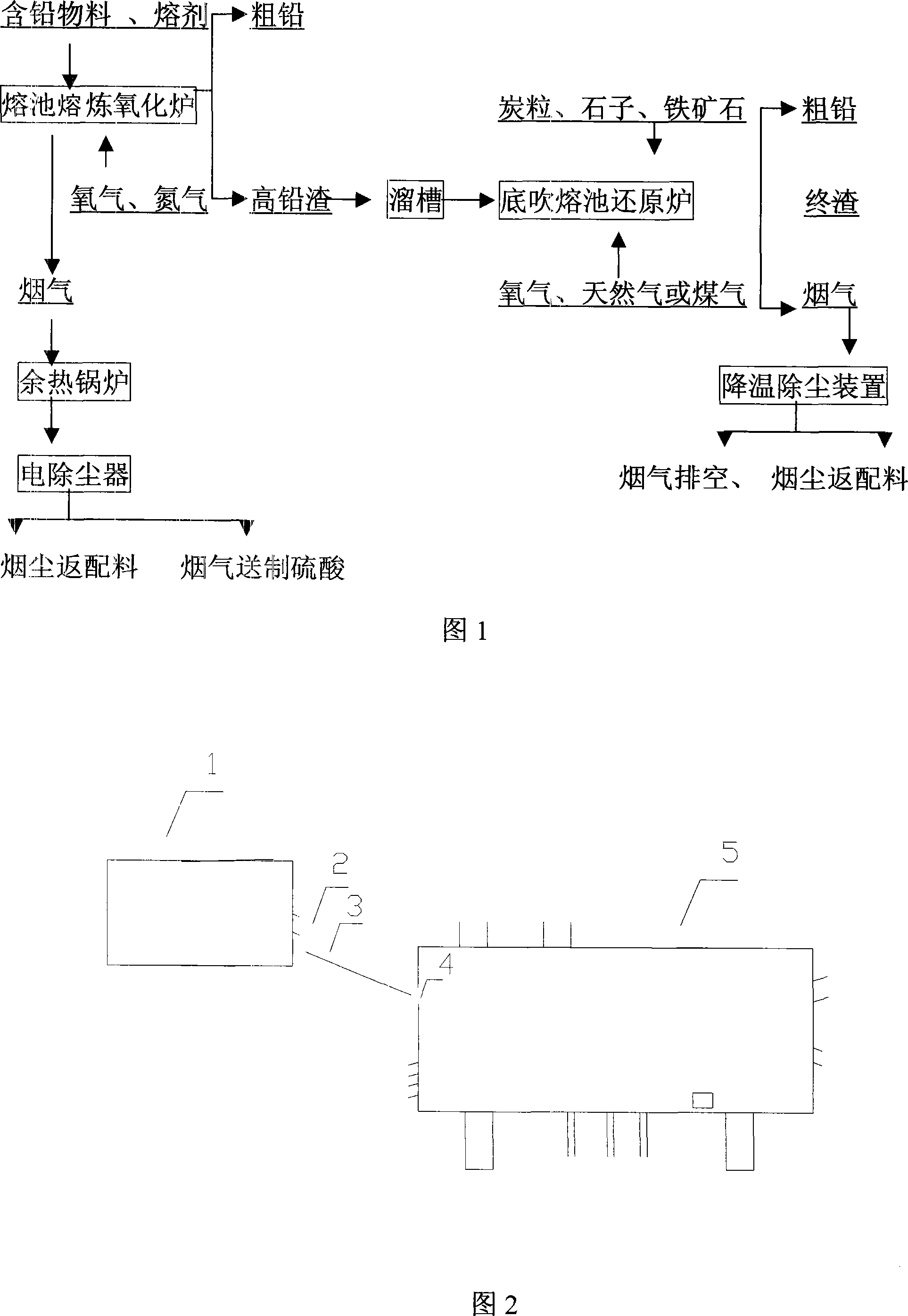

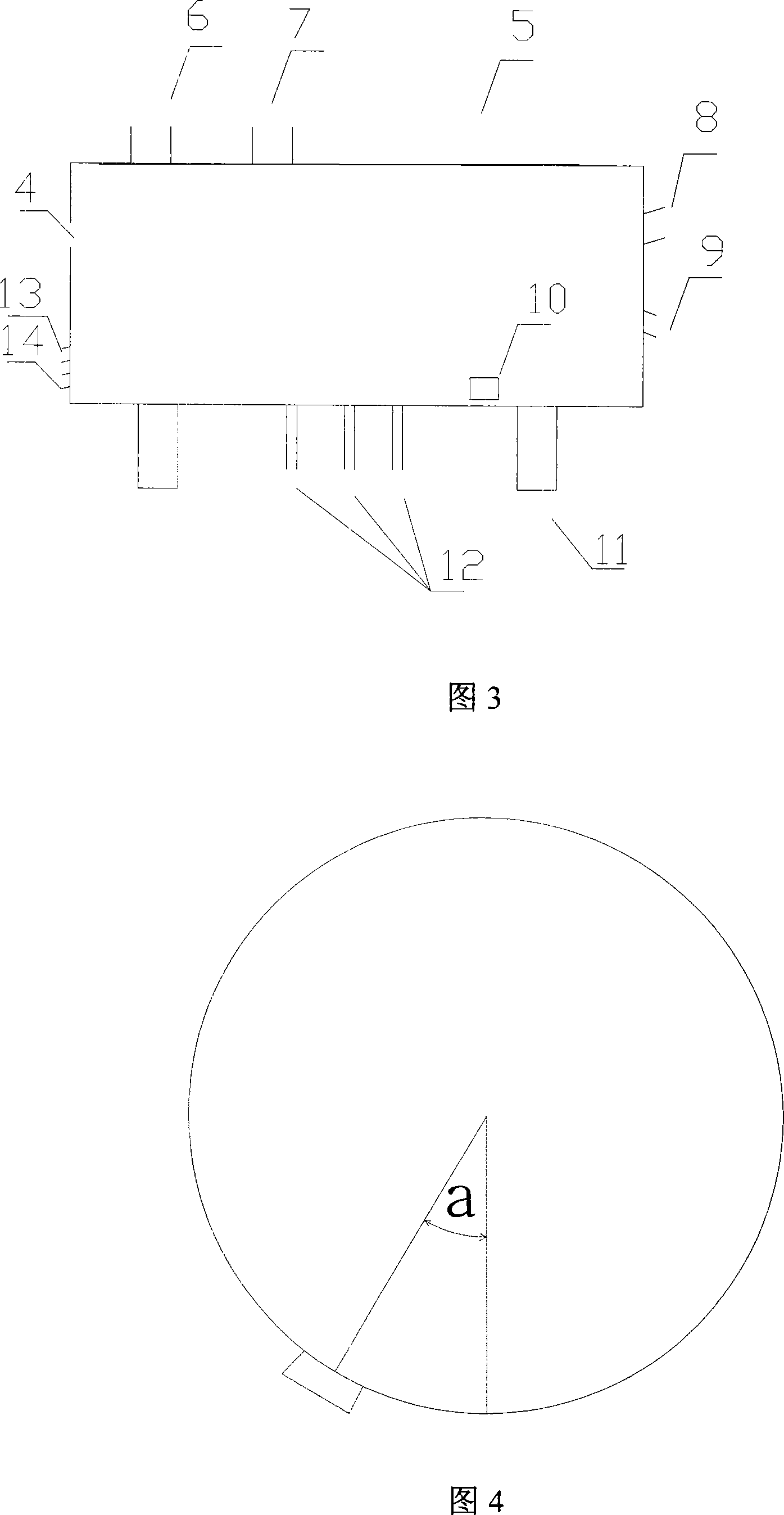

Direct lead smelting method in molten pool and its device

This invention relates to method for smelting lead by using molten pool directly and the device. It comprises the following steps: feeding the high-lead residue melt into bottom-blown molten pool by downspouting to deoxidize; providing melt with oxygen and natural gas or oxygen and gas from bottom or downside of the bottom-blown molten reduction furnace by using gas spray gun; adding carbon particles to reduction furnace from feed opening; the high-lead residue melt is transformed to crude lead, flue gas and final slag through reduction. The device comprises melting bath calcar, and the taphole of melting bath calcar is connected to the feed opening of bottom-blown molten reduction furnace through downspouting, the gas spray gun is installed on the bottom or downside of bottom-blown molten reduction furnace. The invention is characterized by low energy consumption, good work environment and saved investment.

Owner:HENAN YUGUANG GOLD & LEAD

Sand burning preventing coal dust free green sand for casting and preparation method thereof

ActiveCN101733361AReuseRaw sand consumption is lessFoundry mouldsFoundry coresProduction rateCoal dust

The invention relates to a sand burning preventing coal dust free green sand for casting and preparation method thereof. The green sand contains 50-90% of naturally clay-bonded sand, 2-40% of sand burning preventing assistant and 2.5-20% of water by weight percent; the preparation method includes that the naturally clay-bonded sand and the sand burning preventing assistant are mixed in a sand mixing machine and the water is added for mixing to uniform. The green sand of the invention contains no coal dust and can be recycled; the casting mould made by the green sand of the invention is utilized to produce castings, crude sand consumption is low, the surface of casting is not burning-on, surface quality is high, no coal dust is required to add, recycling of moulding sand is good, environmental protection is less, and high temperature mould dismantling improves productivity.

Owner:DONGHUA UNIV

Catalyst used for catalytic synthesizing dimethyl carbonate directly from methanol and carbon dioxide and preparation and using method thereof

The invention discloses a direct catalytic synthesis catalyst to prepare dimethyl carbonate from methanol and carbon dioxide and the preparation and application methods of the catalyst. The catalyst of the invention consists of transitional metal soluble salt, promoter and carrier, with the weight ration from 0.01to 0.5: 0.01to 0.1:1. The preparation method is that: (1) the carrier is impregnated into the transition metal soluble salt solution; (2) the promoter is added into the solution, which is stirred in room temperature, ultrasonically dispersed and stored stationarily in room temperature; (3) the solution is dried, sintered, reduced and activated to produce catalyst. The application method is that: the catalyst is put in high pressure reactor or micro reaction device with the temperature of the catalyst bed controlled between 90 degrees centigrade to 140 degrees centigrade and the reaction pressure between 0.6 to 3.0MPa. The catalyst is applicable in direct catalytic synthesis to prepare dimethyl carbonate from methanol and carbon dioxide. The raw material sources are rich, the cost is low, the preparation method is simple and the operation is easy. The catalyst is easily separated from the products, the reaction conditions are mild and the catalyst can be used repeatedly. The catalyst has high activity and selectivity.

Owner:SUN YAT SEN UNIV

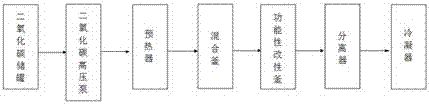

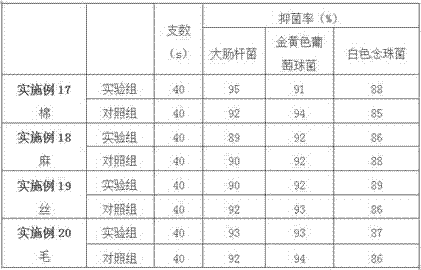

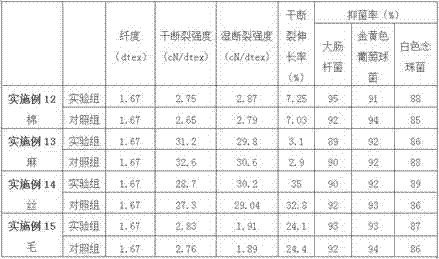

Natural fiber product modified by adopting supercritical carbon dioxide technology and modification method

The invention provides a natural fiber product modified by adopting a supercritical carbon dioxide technology. The modified natural fiber product is a cotton, hemp, silk or wool natural fiber or a yarn, fabric or clothing prepared from the natural fiber. The invention further provides a method for modifying the natural fiber product by adopting the supercritical carbon dioxide technology. The method comprises the step of adding the natural fiber and a vegetable dye and a natural plant extract; the natural fiber is modified by innovatively adopting the supercritical carbon dioxide technology; water or other reagent is not utilized as a solvent, no wastewater or waste is generated or discharged, and the method has the characteristics of ecological environment protection and wide adaptability of fabric varieties and belongs to an environment-friendly functional modification technology. The natural fiber which is functionally modified by adopting the supercritical carbon dioxide technology is uniform in color and luster, extremely good in reproducibility and free of an injury to the natural fiber.

Owner:BESTEE MATERIAL (TSINGTAO) CO LTD

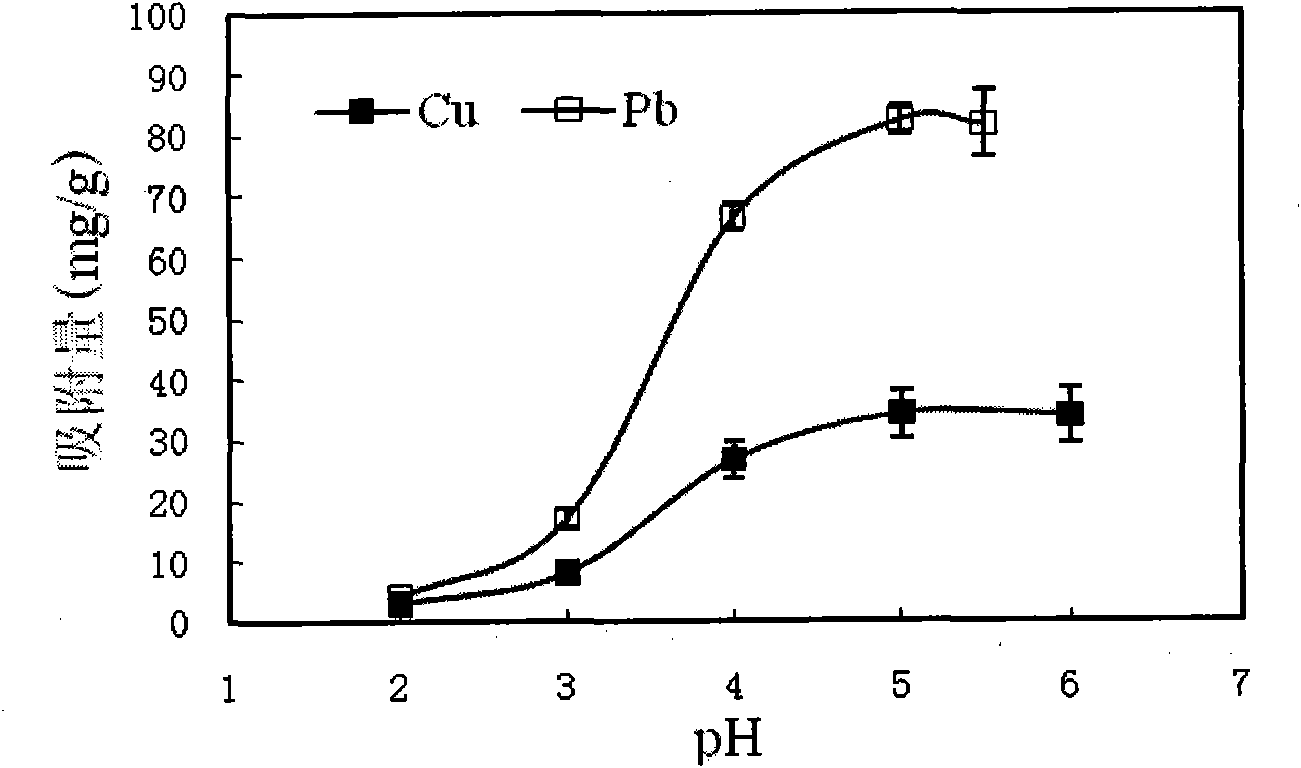

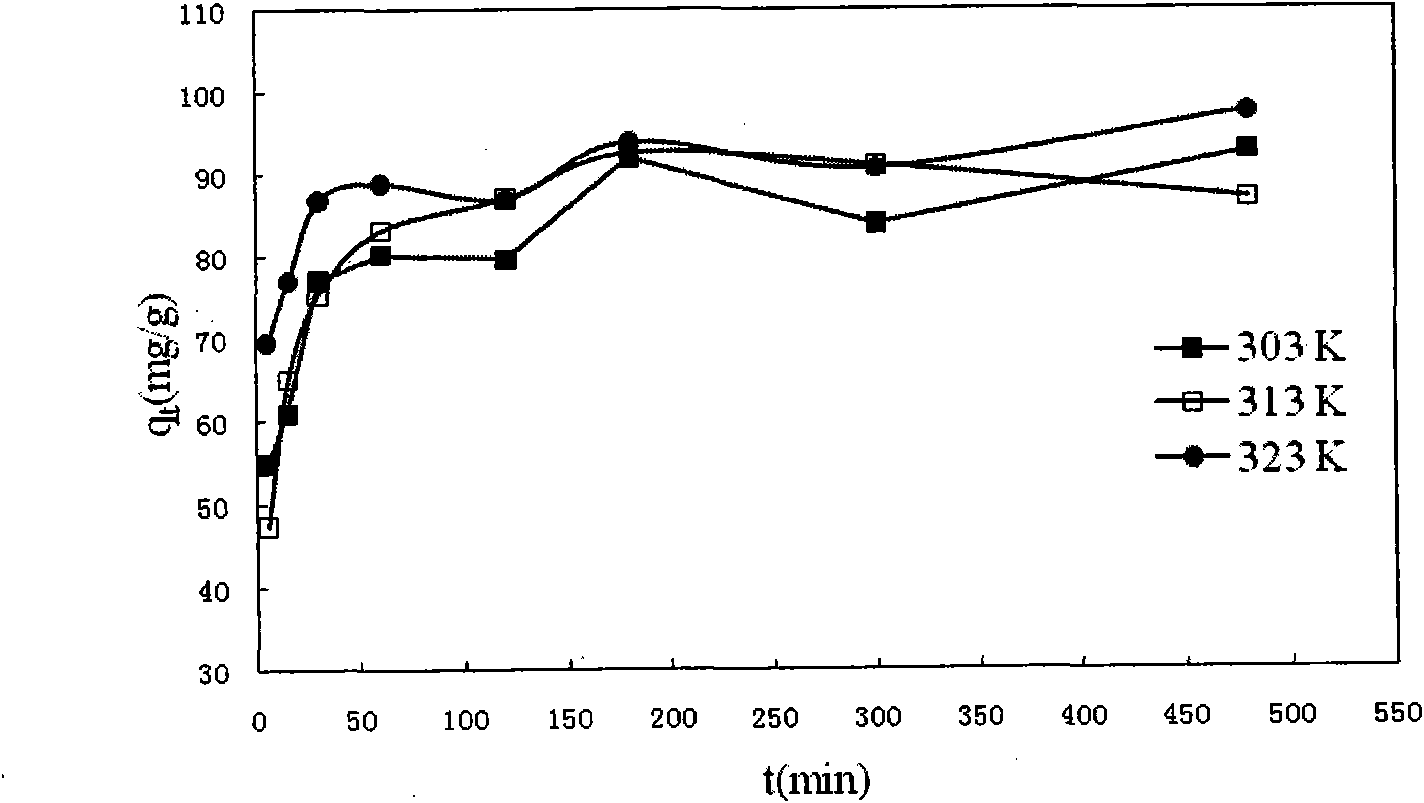

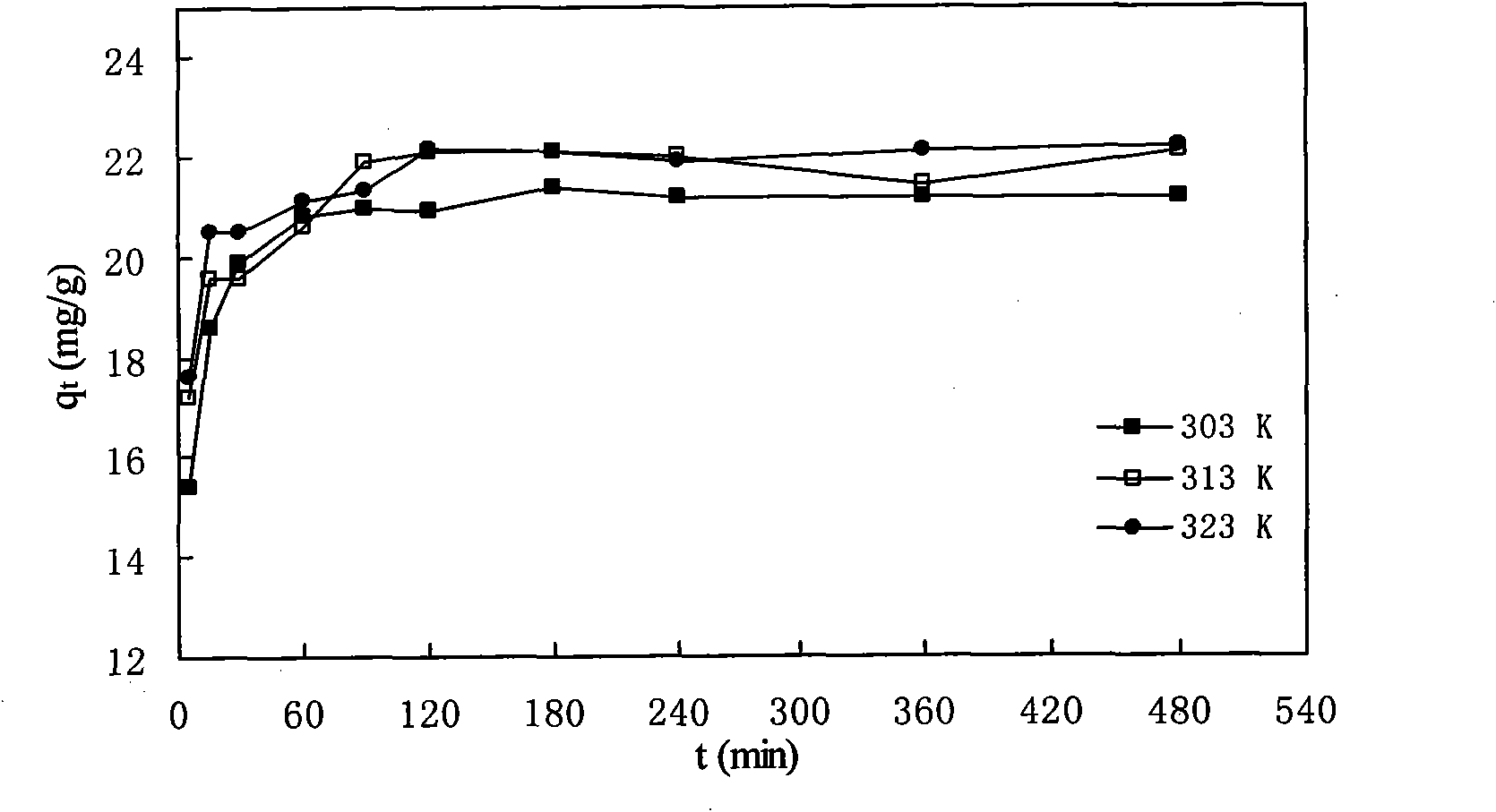

Method for adsorbing and recovering heavy metals of lead and copper by persimmon tannin-containing metal adsorbent

InactiveCN102614834AExtensive sources of raw materialsLow costIon-exchange process apparatusOther chemical processesIonTannin

The invention belongs to the technical field of natural product preparation and especially relates to a method for adsorbing and recovering heavy metals of lead and copper by a persimmon tannin-containing metal adsorbent. The method can be widely used for adsorbing and removing lead and copper ions in waste water and has the advantages of low cost, large adsorption capacity, good environmental benefits and convenient operation. The method is characterized by comprising the following steps of 1, respectively adding a persimmon tannin-containing metal adsorbent and a lead or copper-containing mixed solution having a pH value of 4 to 6 into a reaction vessel according to a ratio of persimmon tannin-containing metal adsorbent mass (by mg) to lead or copper-containing mixed solution volume (by mL) of 1: (3 to 5), wherein the volume of the used lead or copper-containing mixed solution is less than or equal to half of the volume of the reaction vessel, 2, putting the reaction vessel into a shaking table, 3, carrying out shaking adsorption at a shaking-table rotation rate of 100 to 200rpm at a temperature of 10 to 50 DEG C for 12 to 24h, and 4, carrying out filtration so that the lead or copper ions can be reduced into metals and retained in the persimmon tannin-containing metal adsorbent. The method also can be used for adsorbing or recovering lead and copper in waste water by a chromatographic column.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

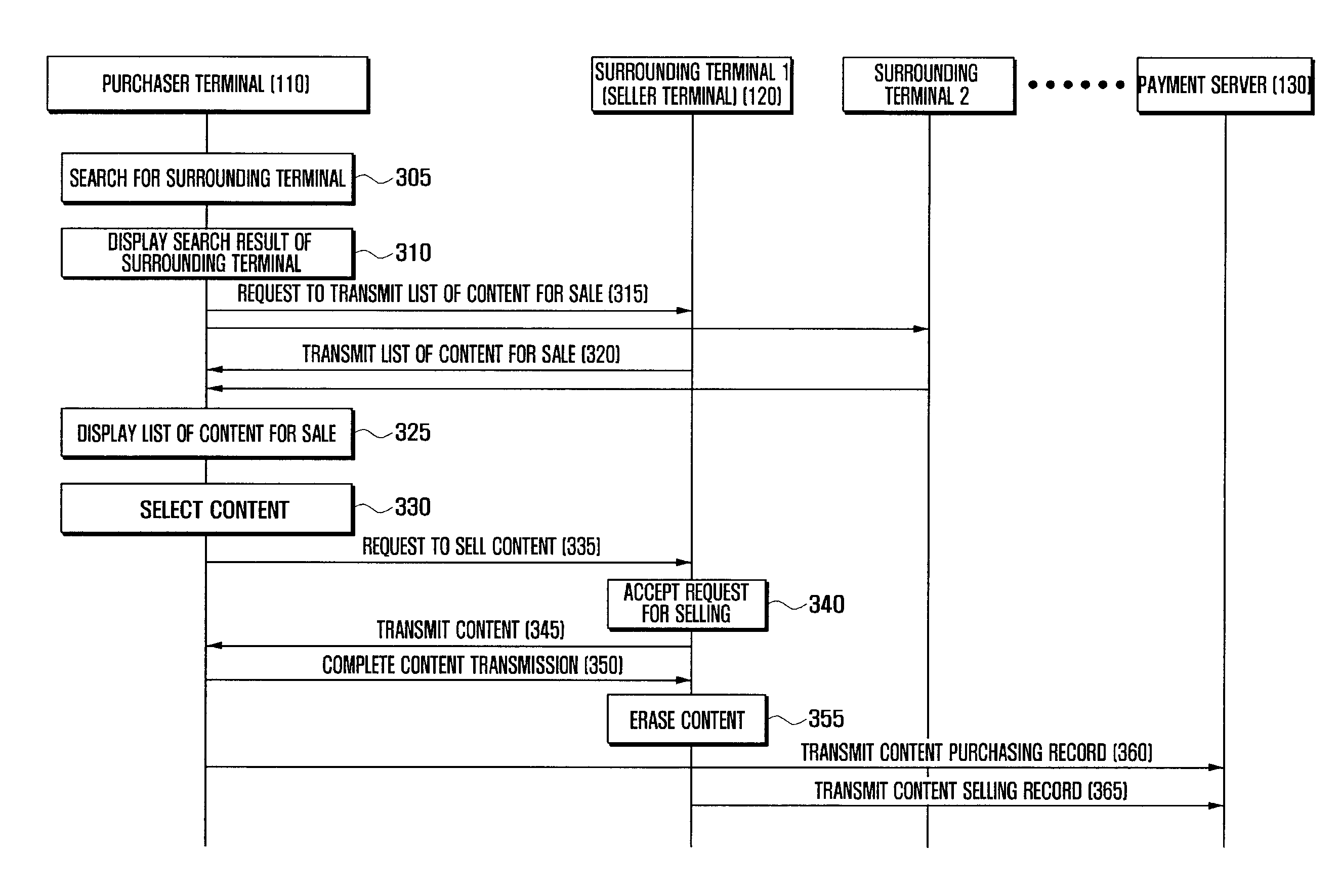

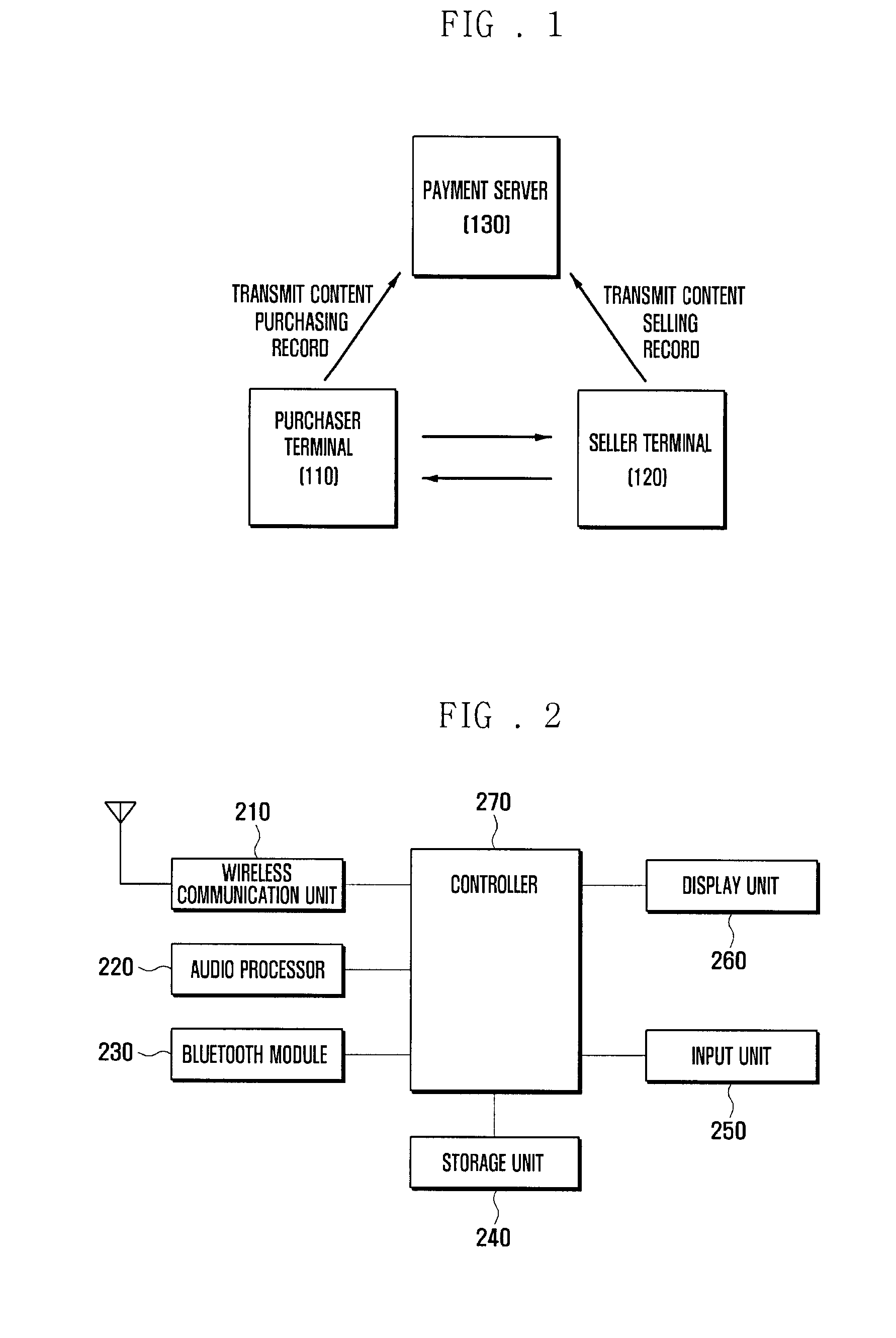

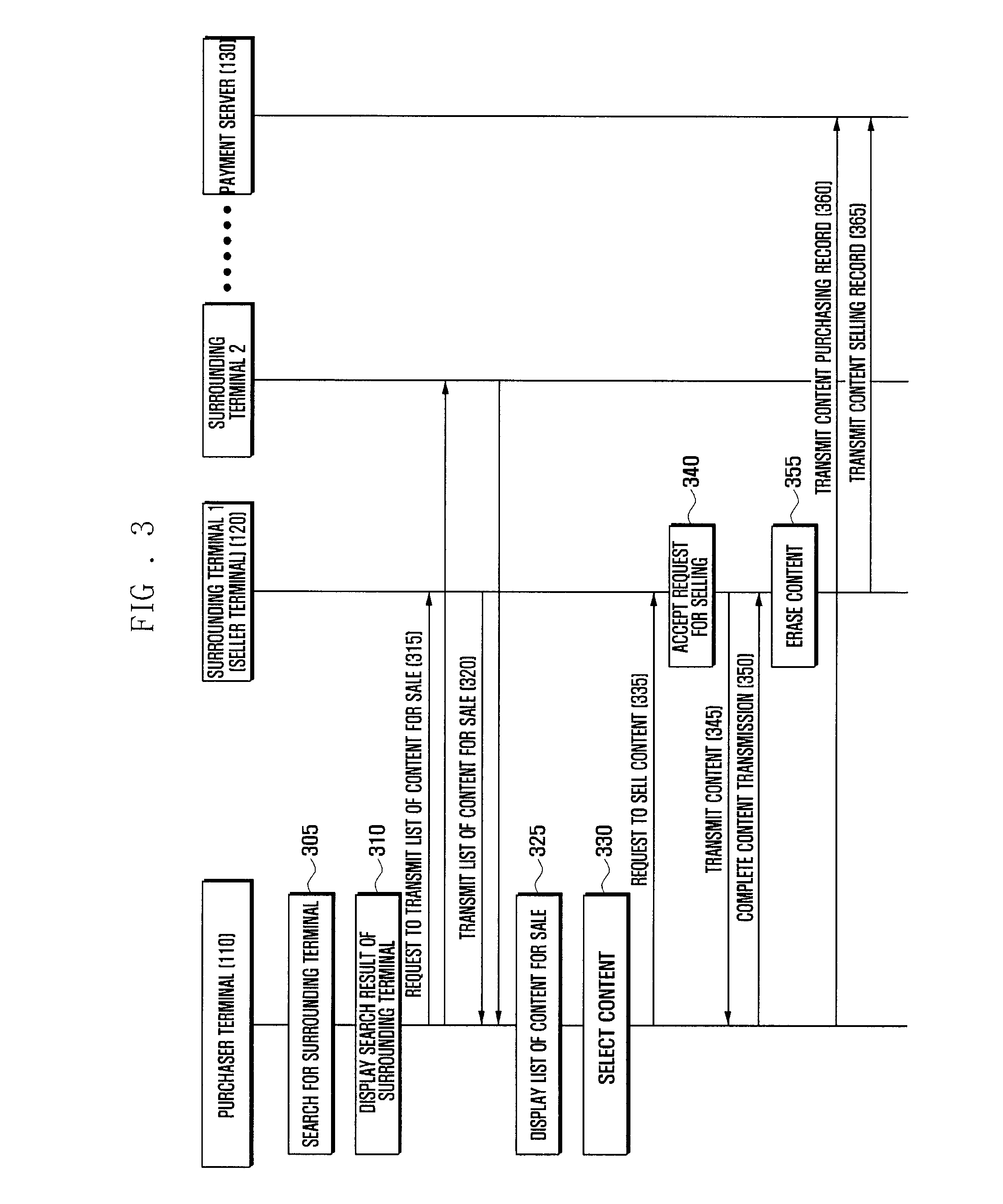

Content transaction method and system

Content transaction method and system are disclosed. The method includes: searching, by a first mobile terminal, for at least one mobile terminal to perform a short-range wireless communication; performing, by the first mobile terminal, a connection with the searched at least one mobile terminal for the communication; receiving, by the first mobile terminal, a list of content for sale from the connected at least one mobile terminal; requesting. from a second mobile terminal storing content to sell, the content by the first mobile terminal; receiving, by the first mobile terminal, the requested content that is requested from the second mobile terminal; and accessing a payment server by the first mobile terminal and the second mobile terminal to transmit content transaction record information.

Owner:SAMSUNG ELECTRONICS CO LTD

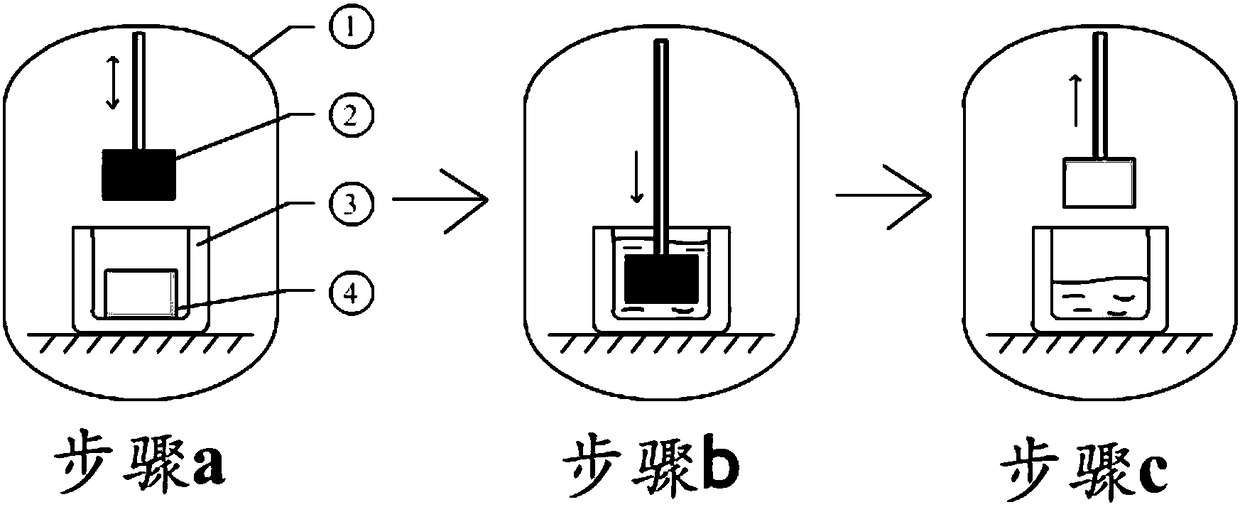

Preparation method of high-heat-conductivity diamond-copper composite

The invention discloses a preparation method of a high-heat-conductivity diamond-copper composite, and relates to a preparation method of a composite. The problems that an existing preparation methodof diamond-copper composite cannot achieve net shape forming, high quality and large batch preparation of large-size sheet samples is solved. The preparation method comprises the steps that diamond powder is placed into a die and compacted to form a precast body, the precast body is hoisted to the lower end of a lifting rod on the upper portion inside an air pressure infiltration furnace, and a crucible containing copper alloy is placed below the precast body in the furnace; vacuumizing is carried out, heating and copper melting are carried out under protection of inert gas, the lifting rod descends, pressurization infiltration is carried out, pressure is kept for cooling, pressure is released, and finally the die is removed. The preparation method has the beneficial effects that high-efficiency mass production can be achieved, the mechanical property is high, the rate of finished products is high, large-size sheet samples can be prepared, sample heat conductivity is improved, the preparation cost is low, the content of impurities is low, and the forming die and the crucible can be repeatedly used. The preparation method is applicable to preparing the high-heat-conductivity diamond-copper composite and component.

Owner:HARBIN INST OF TECH

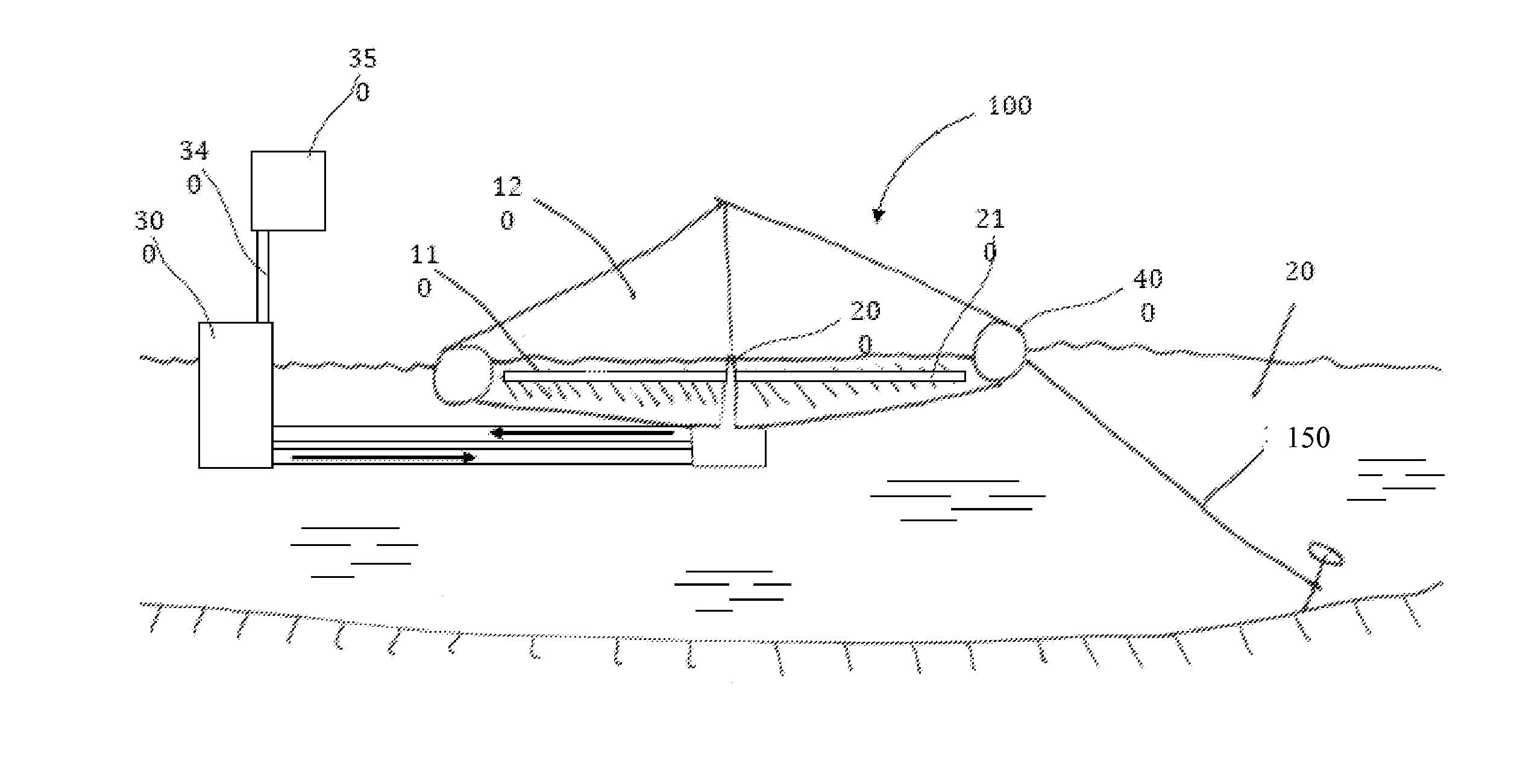

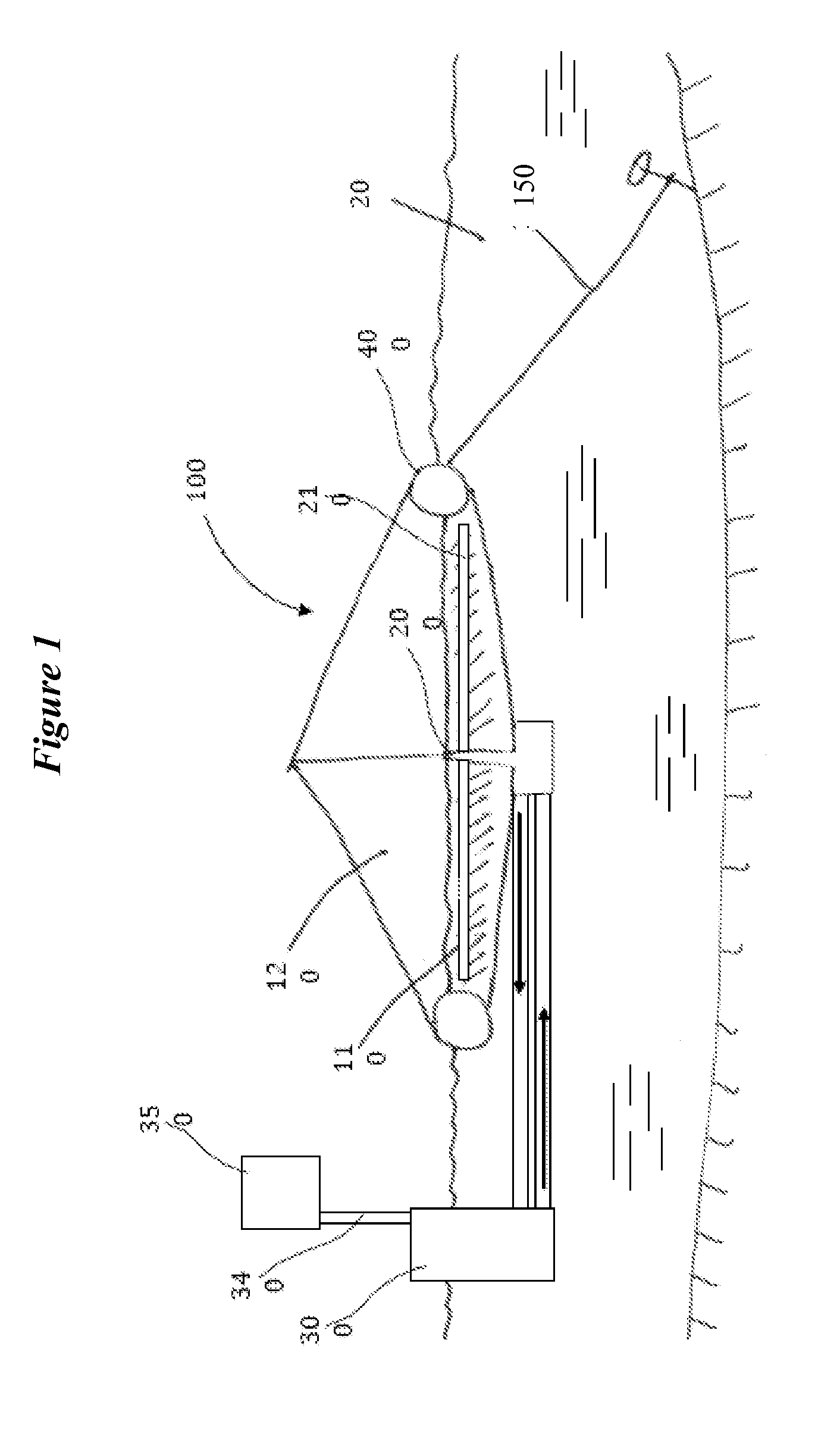

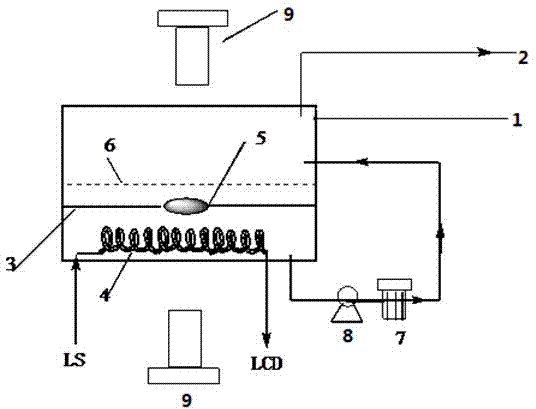

Outdoor cultivator for photosynthetic microorganisms

InactiveUS20120115210A1Good thermal controlReuseBioreactor/fermenter combinationsBiological substance pretreatmentsOrganismContamination

A novel waterborne cultivator, which provides the benefits of known systems for culture of photosynthetic micro-organisms in a novel configuration, incorporating a simplified, two-phase rotary mixing and gas injection system, the two phases being liquid and gas (CO2). The mixing system provides optimum growth conditions through increased turbulent vertical mixing and increased levels of dissolved CO2 throughout the cultivator via injection of flue gas or other CO2-bearing gas stream. The system thus provides efficient capture and sequestration or reuse of CO2 while producing valuable biomass for food, feed, and fuel use. The waterborne configuration provides further benefits of passive temperature control and automatic leveling for consistent culture depth. Additional benefit is provided by an enclosed design which reduces contamination and evaporative loss by isolating the photosynthetic culture from the outside environment. The simplified and well-integrated design of the cultivator and mixing system greatly reduces capital and operating costs compared to previously known systems.

Owner:ELEMENT CLEANTECH

Cleaning method and equipment of spinneret plate for polyacrylonitrile fiber

InactiveCN104775167AImprove dissolution efficiencyIncrease the probability of collisionSpinnerette packsNon-surface-active detergent solventsBiochemical engineeringUltrasonic vibration

The invention relates to a cleaning method of a spinneret plate, in particular to a cleaning method and cleaning equipment of the spinneret plate for polyacrylonitrile fiber. In the vacuum cleaning environment, an alkaline spinneret plate cleaning solution is heated, circulating dissolved cleaning is performed on polyacrylonitrile (PAN) on the spinneret plate, auxiliary cleaning of ultrasonic vibration wave oscillation is performed in the whole cleaning process, and the cleaning solution is filtered by an external circulating system, so that no impurity in the cleaning solution in the vacuum environment is guaranteed. The cleaning method has the advantages of short process flow, simple equipment and good cleaning effect, and the cleaning solution can be reused.

Owner:ZHONGFU SHENYING CARBON FIBER

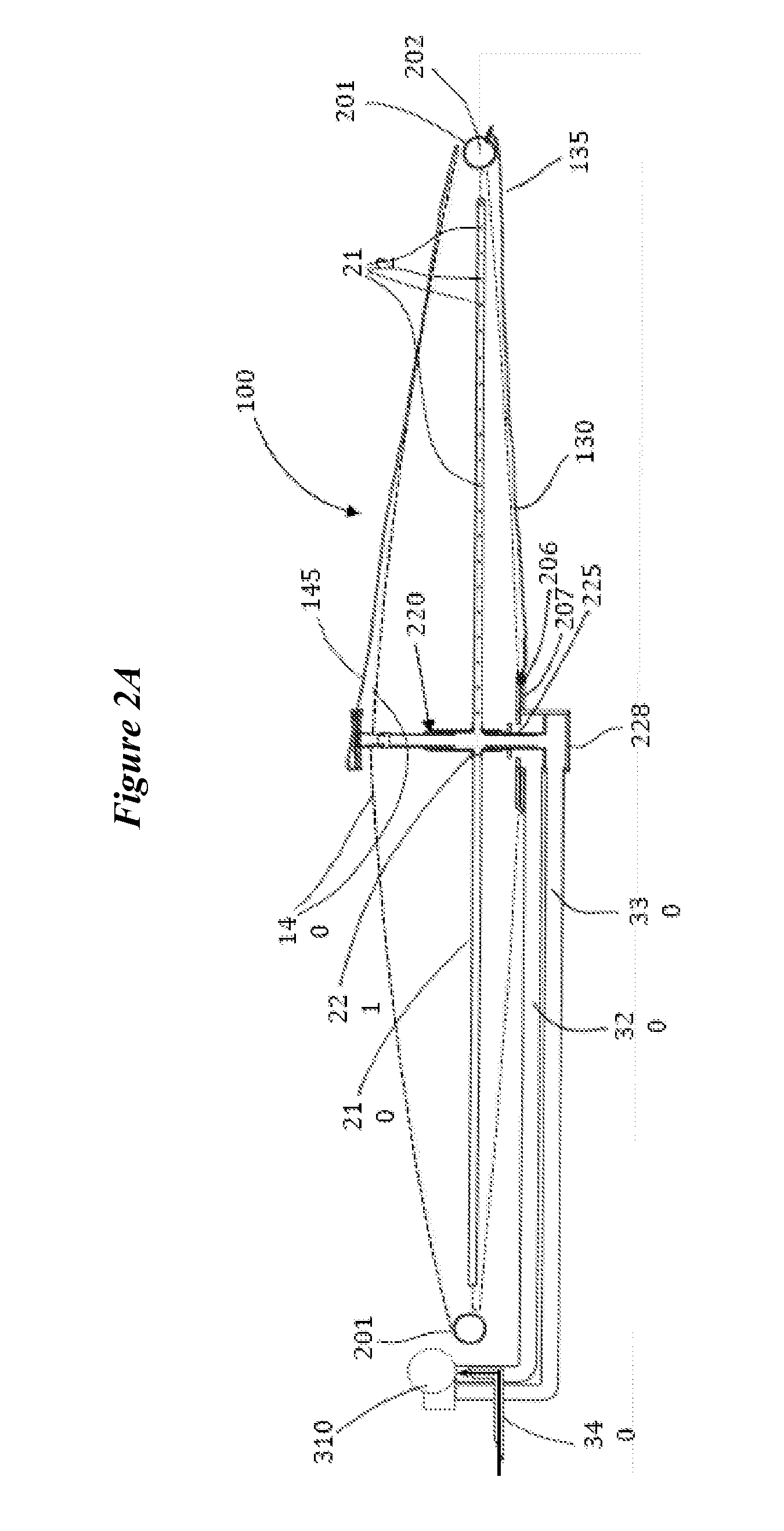

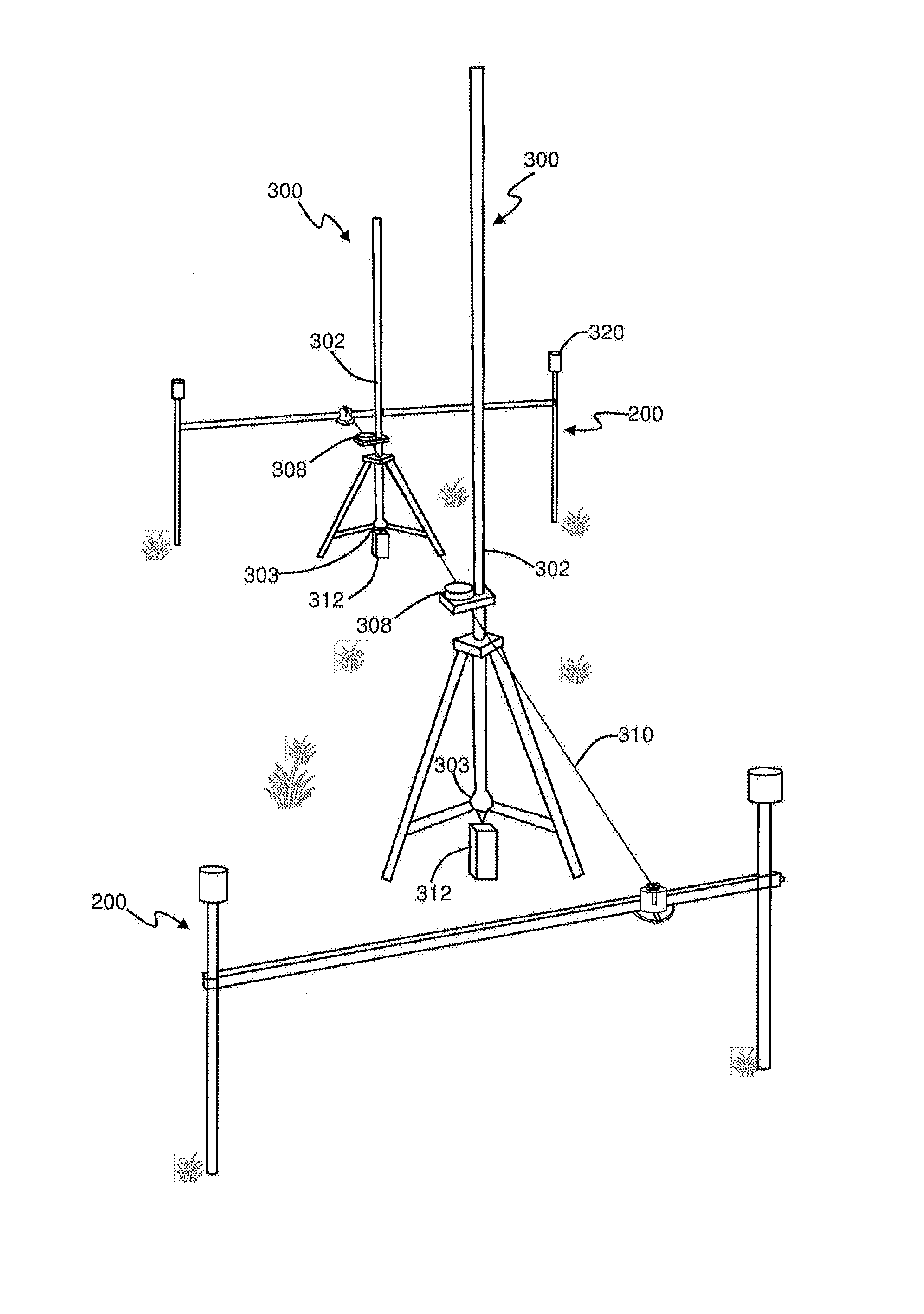

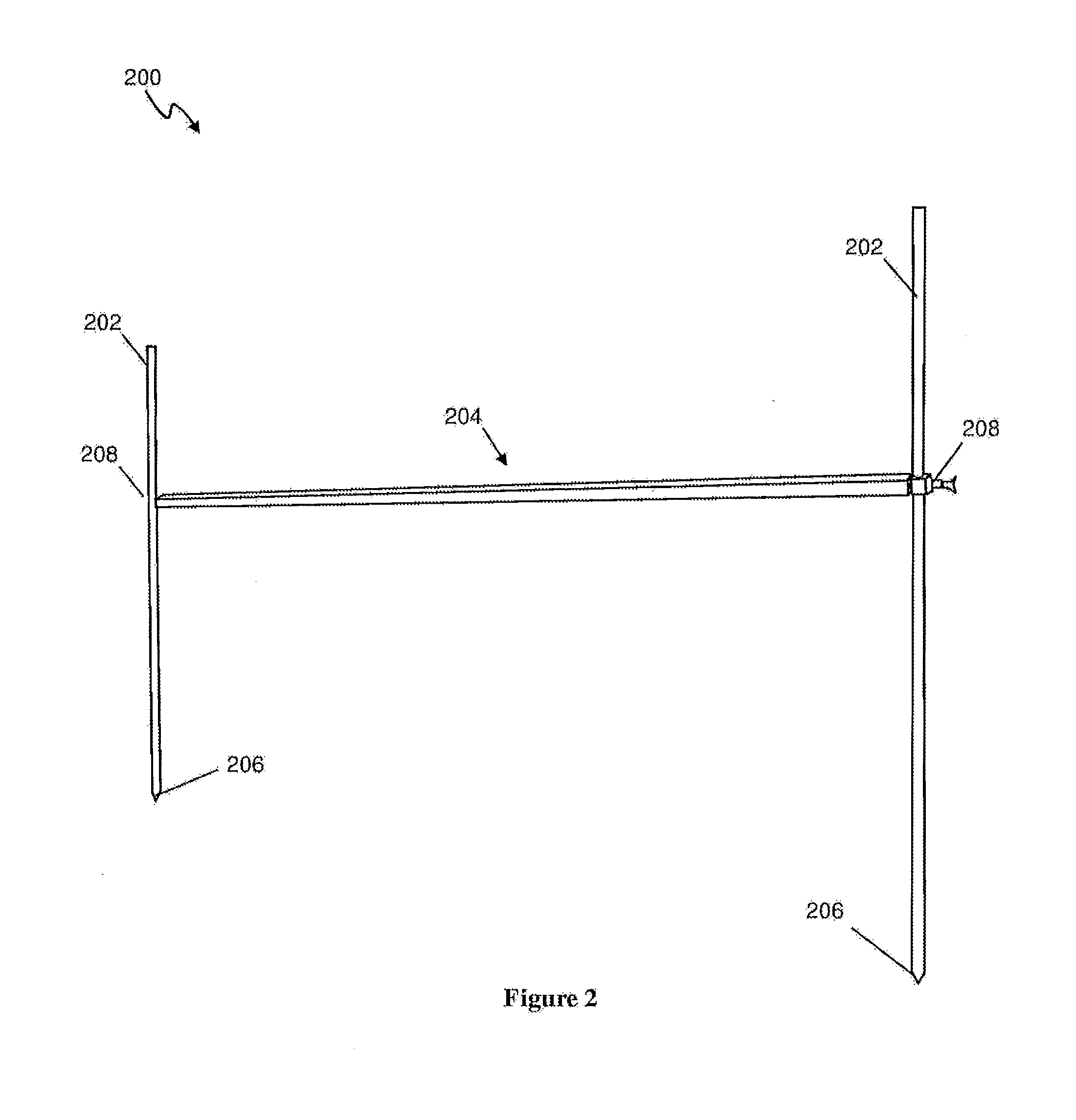

Building Profile

ActiveUS20160252349A1Conveniently fastenedEfficient and convenient removalSurveyor's staffsMovable markersEngineering

Owner:EZYPROFILE SYST

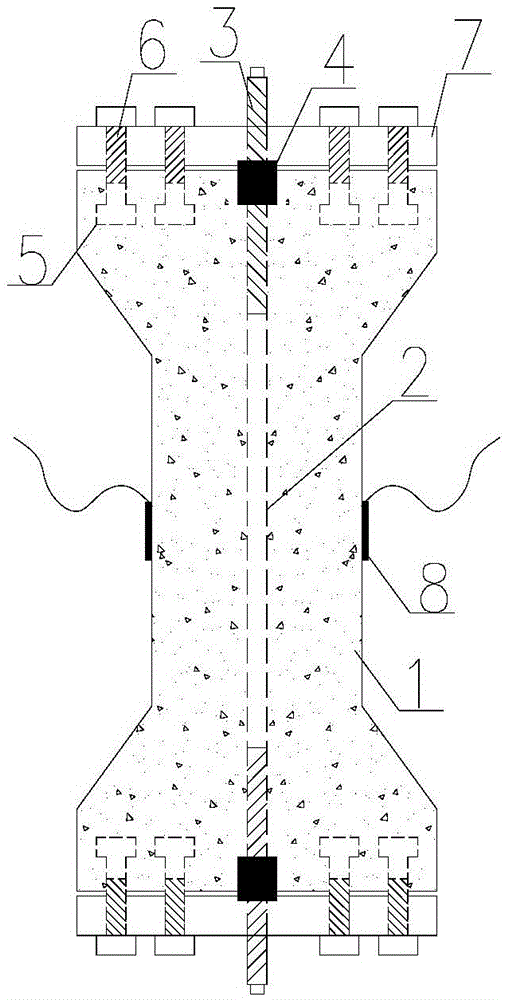

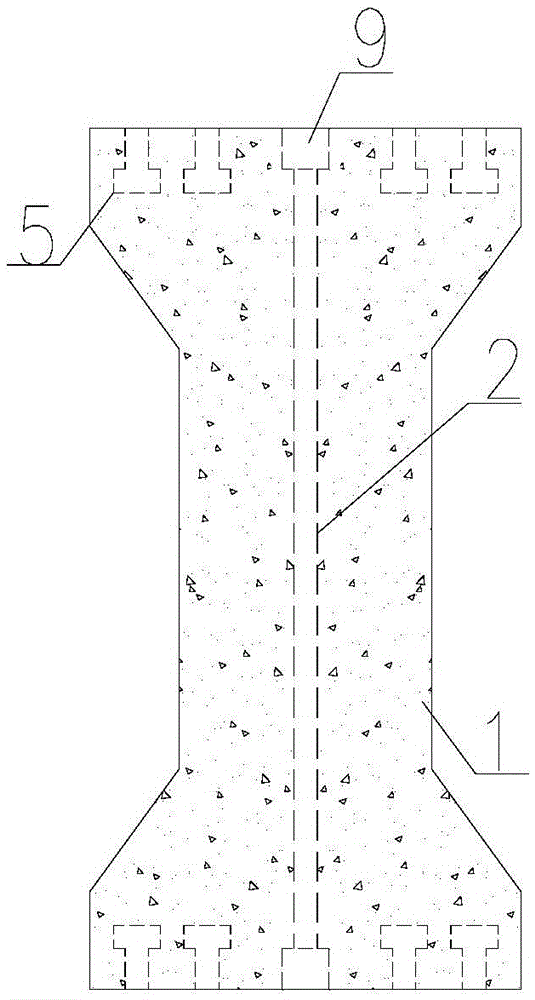

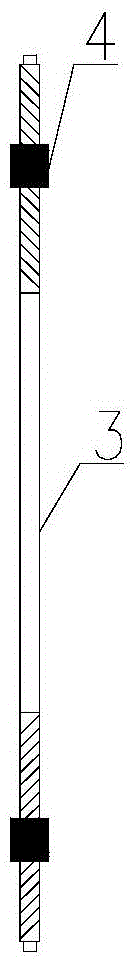

Test device for axial tension load applied by concrete member

ActiveCN105424478AEasy to operateLow costMaterial strength using tensile/compressive forcesMaterial testing goodsSteel platesScrew joint

The invention relates to a test device for an axial tension load applied by a concrete member. The test device comprises a concrete axial tension test piece, bearing steel plates loaded at the two ends of the concrete axial tension test piece, a plurality of T-shaped embedded parts with internal threads, a bearing screw rod and a strain gauge, wherein axially distributed reserved through holes are formed on the concrete axial tension test piece; the plurality of T-shaped embedded parts are respectively embedded at the two ends of the concrete axial tension test piece; the thread sections of the T-shaped embedded parts are pointed to the exterior of the concrete axial tension test piece; the bearing screw rod penetrates through the reserved through holes; nuts are arranged at the two ends of the bearing screw rod; the bearing steel plates are arranged on the outer side of the nuts; the thread sections of the T-shaped embedded parts are in screw joint with fastening bolts; the strain gauge is mounted on a side wall of the concrete axial tension test piece; a signal output end of the strain gauge is electrically connected with an external strain meter. The test device provided by the invention has the beneficial effects that the loading device can overcome the difficulty in applying the axial load; the operation is simple; the cost is low; the test device is anti-corrosion and is reusable; the volume of the test device is small; the fine threads are arranged at the two ends of the screw rod; the loading is labor-saving; the load size is easily controlled.

Owner:ZHEJIANG UNIV OF TECH

Activator for chemical combination of phenol by benzene hydroxide radical and the application method

InactiveCN101032697AEasy to manufactureReuseOrganic chemistryOrganic compound preparationPtru catalystEthylic acid

The present invention discloses one kind of catalyst for hydroxylating benzene to synthesize phenol and its application method. The catalyst with molecular sieve as carrier is prepared through soaking the carrier to support salt of transition metal, roasting, mixing with phthalic anhydride, urea and ammonium molybdenate, and in-situ solid phase synthesis. It is used in the oxidation of benzene dissolved in solvent comprising acetic acid and water with oxygen as oxidant in the presence of reductant ascorbic acid to synthesize phenol. The catalyst of the present invention has no loss of active components, easy separation from the reaction system, mild reaction condition, high yield of target product phenol and other advantages.

Owner:EAST CHINA NORMAL UNIV

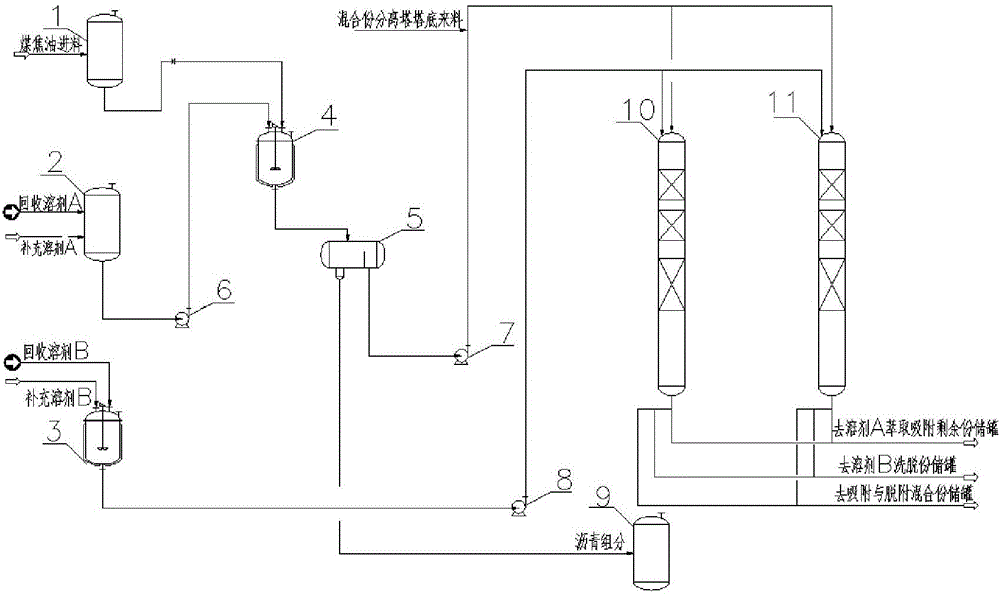

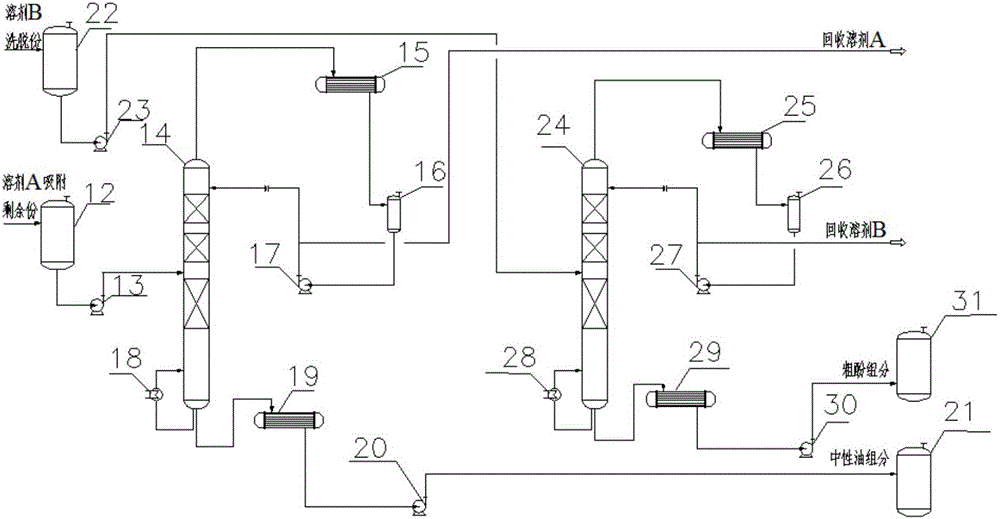

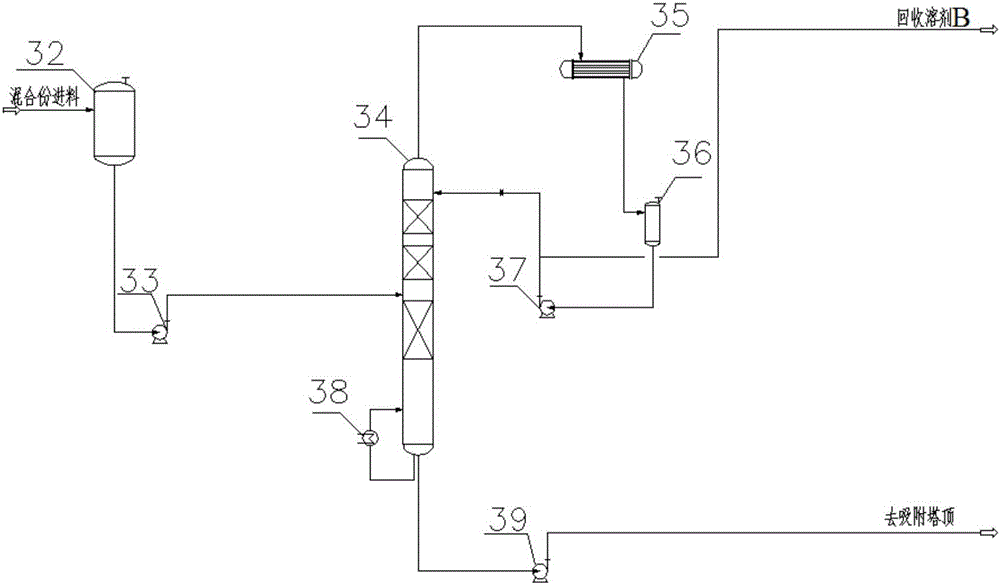

Device and process for continuous separation of coal tar components

ActiveCN106478379ASimple structureSmall footprintOrganic chemistryOrganic compound preparationSolventPhenol

The invention discloses a device and a process for continuous separation of coal tar components. A solvent A and coal tar are subjected to mixing, extracting and stirring in an extraction reactor, and a mixture of the coal tar and the solvent A is separated in a separation tank to obtain an asphalt component; by arrangement of two adsorption towers, continuous performing of adsorption and elution is realized, a solvent A extract without the asphalt component is allowed to pass through the adsorption towers, and mixed liquid obtained after adsorption separation enters a neutral oil component separation tower to realize rectification to obtain a neutral oil component and the recovered solvent A; a solvent B is pressurized through a solvent B feeding pump and eluted through the adsorption tower which adsorbs the solvent A extract, eluant enters a crude phenol component separation tower to obtain a crude phenol component and the recovered solvent B through rectification separation. The process which is a green separation process is free of waste water, waste residues and waste gases and has advantages of mild operation conditions, simplicity and convenience in operation, low process and equipment cost, low input and the like.

Owner:NORTHWEST UNIV(CN)

Method of recovering terramycin from terramycin production mother liquid

InactiveCN101033199AEasy to manageSimple methodCarboxylic acid amide separation/purificationChemistryMother liquor

This invention relates to a method for recovering terramycin from terramycin mother liquid, which adds acid or alkali to a terramycin mother liquid to adjust pH to 2-9 to be filtered and get the clarified mother liquid, and puts strong polarity large hole adsorption resin into an adsorption post to adsorb terramycin from the clarified mother liquid controlling the temperature at 10-15deg.C and flow rate at 2-16BV / h, takes ethanol, methanol or acetone organic solvent as the eluent and controls the temperature at 25-60deg.C and flow rate at 1-4BV / h to carry out desorption, then the desorption solution is distilled to separate out terramycin and recovers organic solvent.

Owner:NANJING UNIV

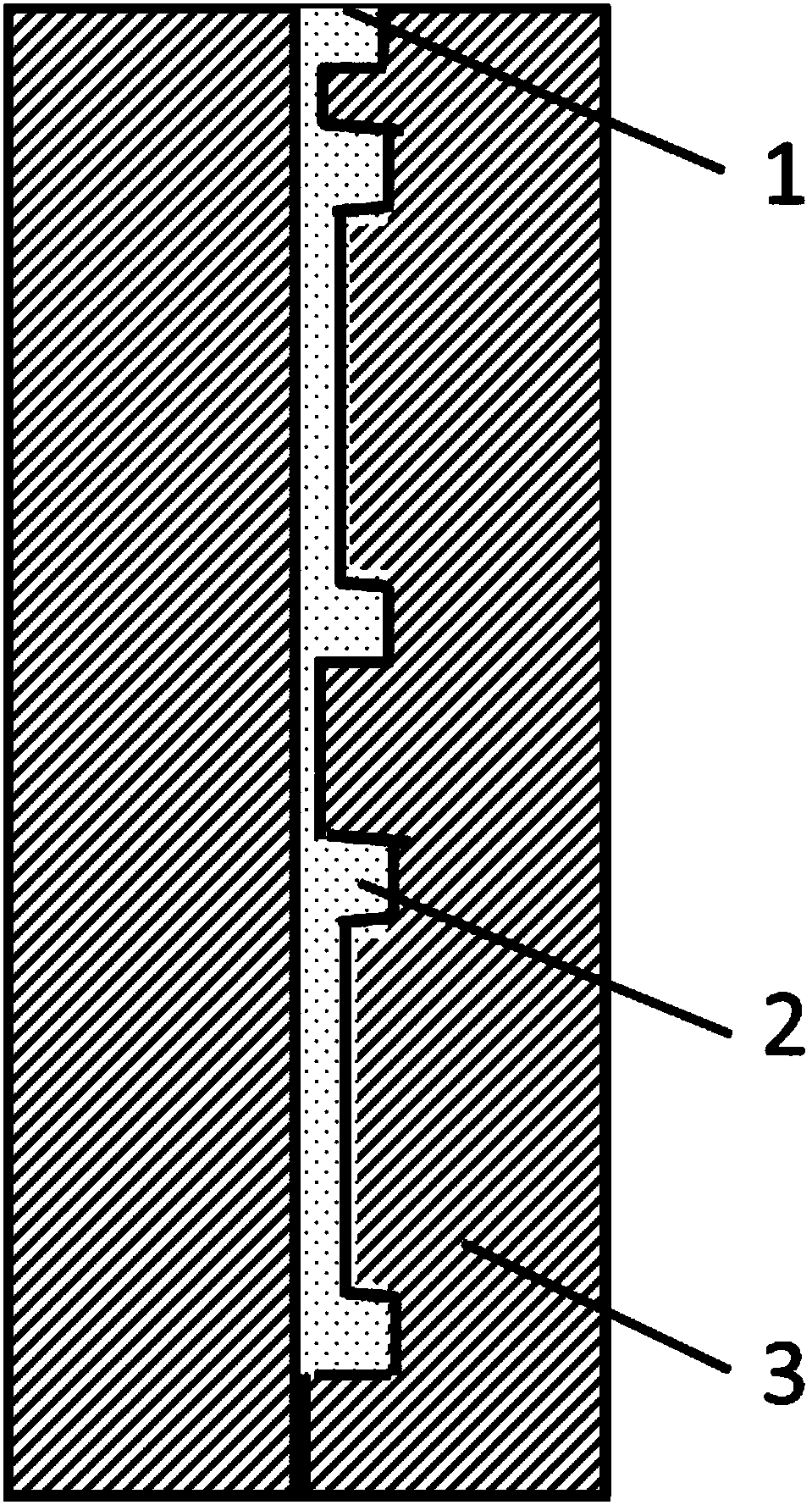

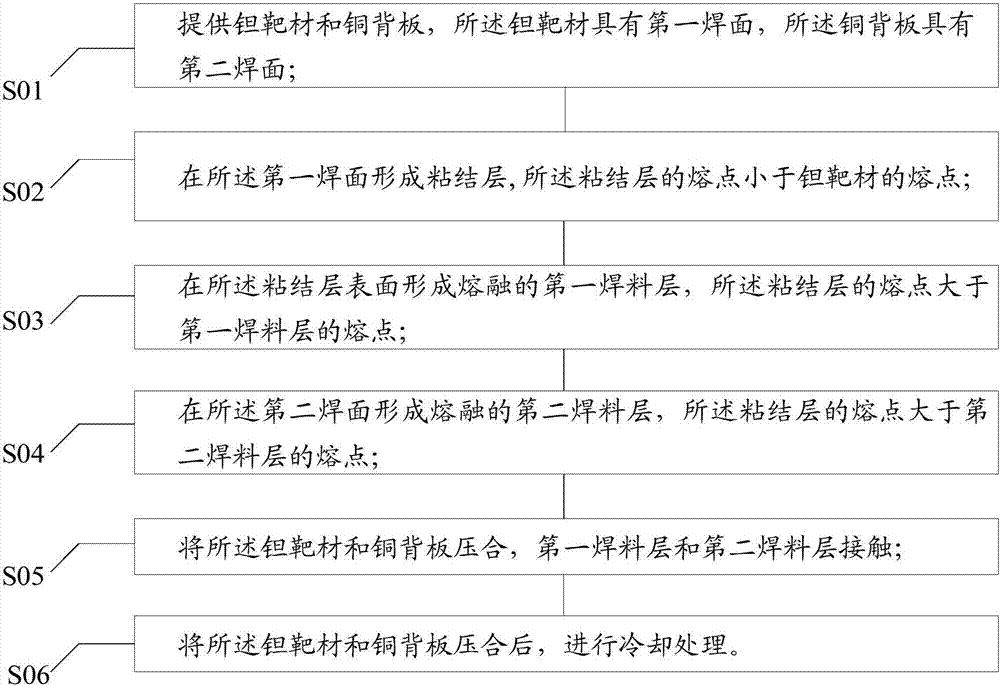

Welding method of tantalum target module

InactiveCN107511599AFusion simpleImprove welding strengthVacuum evaporation coatingSputtering coatingCopperWeld strength

The invention discloses a welding method of a tantalum target module. The welding method of the tantalum target module comprises the following steps: the tantalum target and a copper back plate are provided; the tantalum target is provided with a first welding surface; the copper back plate is provided with a second welding surface; a bonding layer is formed on the first welding surface; the melting point of the bonding layer is lower than the melting point of the tantalum target; a molten first solder layer is formed on the surface of the bonding layer; the melting point of the bonding layer is higher than the melting point of the first solder layer; a molten second solder layer is formed on the second welding surface; the melting point of the bonding layer is higher than the melting pint of the second solder layer; the tantalum target and the copper back plate are pressed; the first solder layer and the second solder layer are contacted; and the tantalum target and the copper back plate are pressed for cooling. As the bonding layer is formed on the first welding surface, and the melting point of the bonding layer is lower than the melting point of the tantalum target and higher than the melting points of the first solder layer and the second solder layer, the welding strength of the cooled tantalum target with the first solder layer and the second solder layer is improved, the welding strength of the tantalum target and the copper back plate is improved, and the copper back plate can be recycled.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

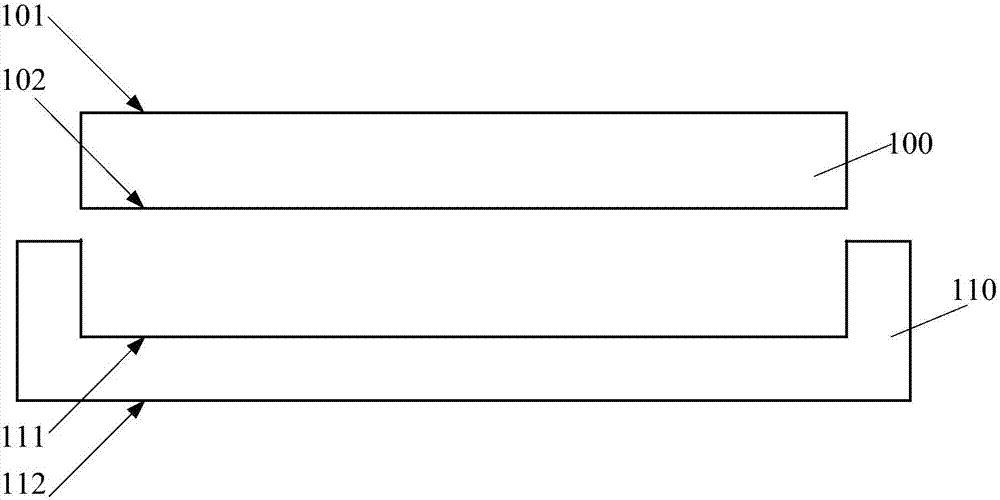

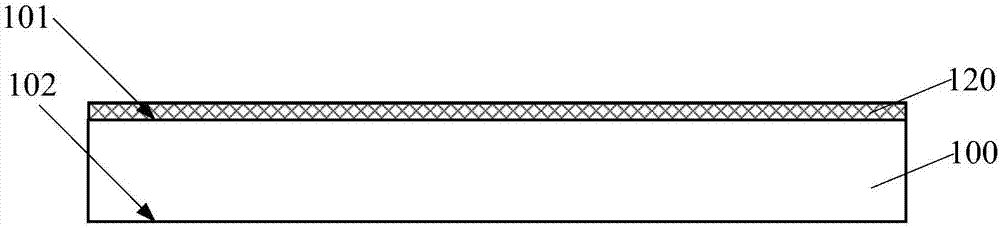

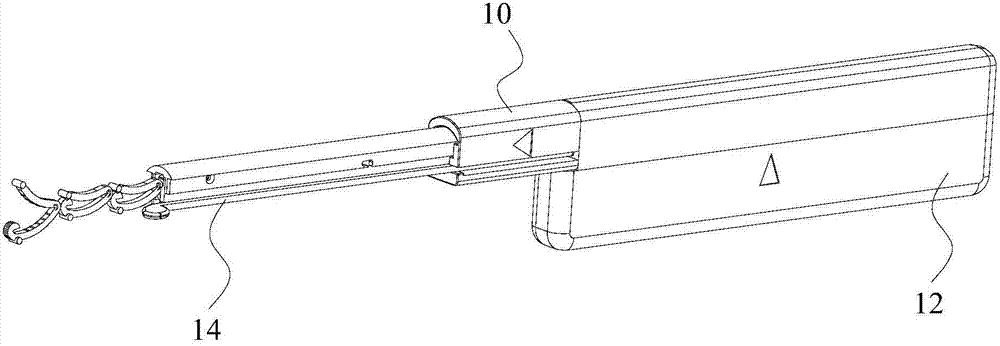

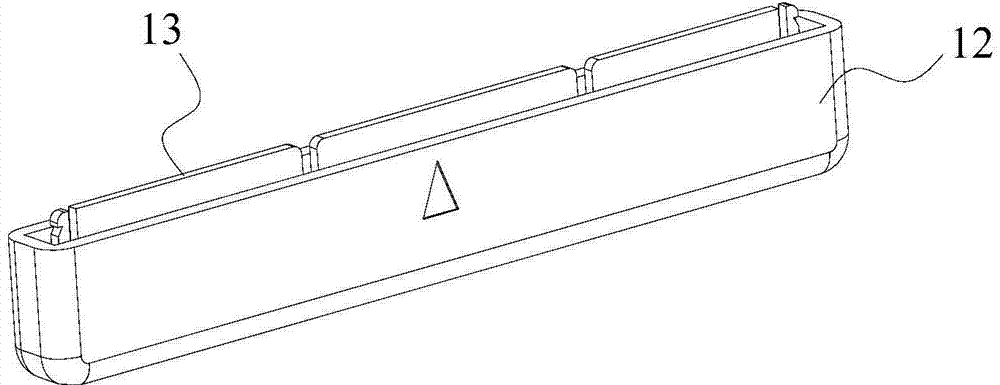

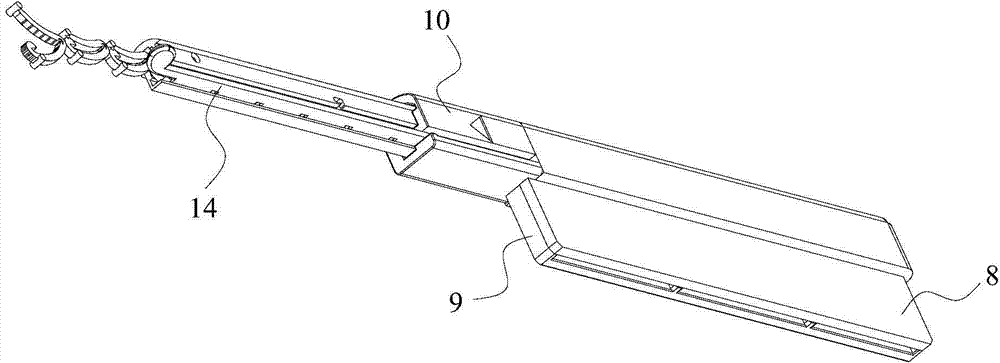

Packing box used for loading hemostatic clips into charger

The invention discloses a packing box used for loading hemostatic clips into a charger. The packing box comprises a box body formed by an upper cover plate and a lower cover plate which are buckled, wherein a conveying channel used for placing squeezed-state hemostatic clips is arranged in the box body; one side of the box body is provided with a transition guide sleeve capable of carrying out fracture connection; a transition cavity which is used for inserting into the charger and is in butt joint with the outlet of the conveying channel is arranged in the transition guide sleeve; a compression channel which is vertically communicated with the conveying channel is also arranged in the box body; a sliding block which is used for squeezing the hemostatic clips into the squeezed state is in sliding fit in the compression channel. According to the packing box, the hemostatic clips can be quickly guided into the empty charger in advance so as to conveniently replace the hemostatic clips in the charger and reuse the charger and the clip applier of the hemostatic clips.

Owner:ZHEJIANG APELOA JIAYUAN BIOMEDICAL MATERIAL

Mugwort salt drug physiotherapy bag for neck-shoulder and lumbar vertebra pains and rheumatoid joint pains

The invention provides a mugwort salt drug physiotherapy bag for neck-shoulder and lumbar vertebra pains and rheumatoid joint pains. The mugwort salt drug physiotherapy bag is prepared from salt, Chinese mugwort leaf, garden balsam stem, obscured homalomena rhizome, cassia twig, common clubmoss herb, mulberry twig, divaricate saposhnikovia root, safflower, turmeric, clematis root, Chinese taxillus twig and notopterygium root. A preparation method comprises the following steps: putting common mugwort fibers, grounded drug materials and salt particles into a mixed stirring barrel, performing stirring and uniform mixing, and then putting into a cloth bag with high air permeability. The size and shape of the mugwort salt drug physiotherapy bag are designed according to common parts, and a mode of fixing the mugwort salt drug physiotherapy bag to a wounded part of a patient can be arbitrarily selected. In a using process, the mugwort salt drug physiotherapy bag is heated and then acts on a pain spot, drugs permeate into a deep layer of the skin of a human body through meridian transmission, blood circulation is promoted, and meridian is unblocked, so that the aims of conditioning an organism and physically treating diseases are achieved; healthcare salt in the mugwort salt drug physiotherapy bag can have a unique treatment effect on soreness, swelling and pains caused by scapulohumeral periarthritis, lumbar muscle degeneration, bone spur, cervical spondylosis, protrusion of intervertebral disc, rheumatoid itai-itai disease, dysmenorrhea and the like.

Owner:中盐皓龙盐化有限责任公司

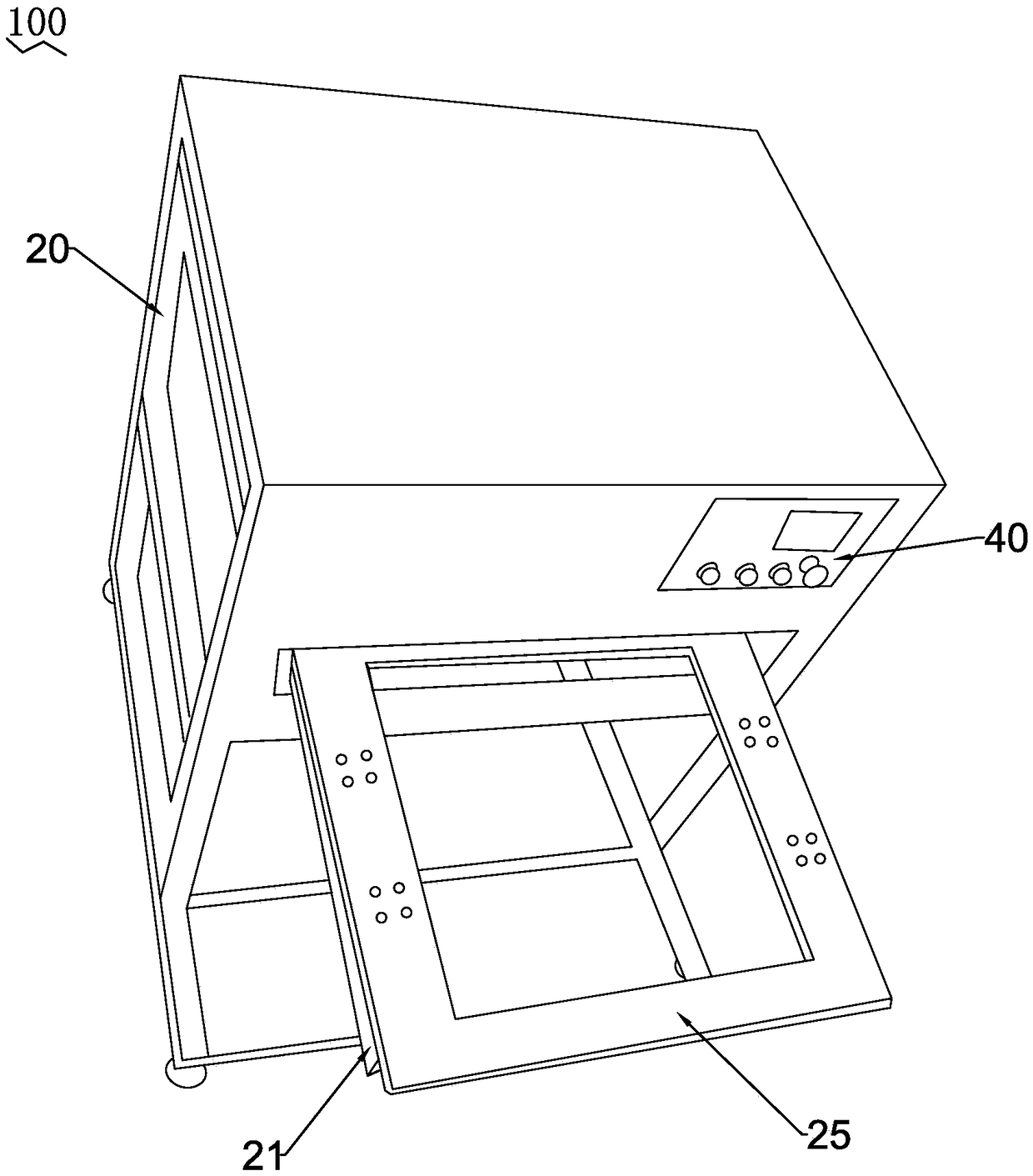

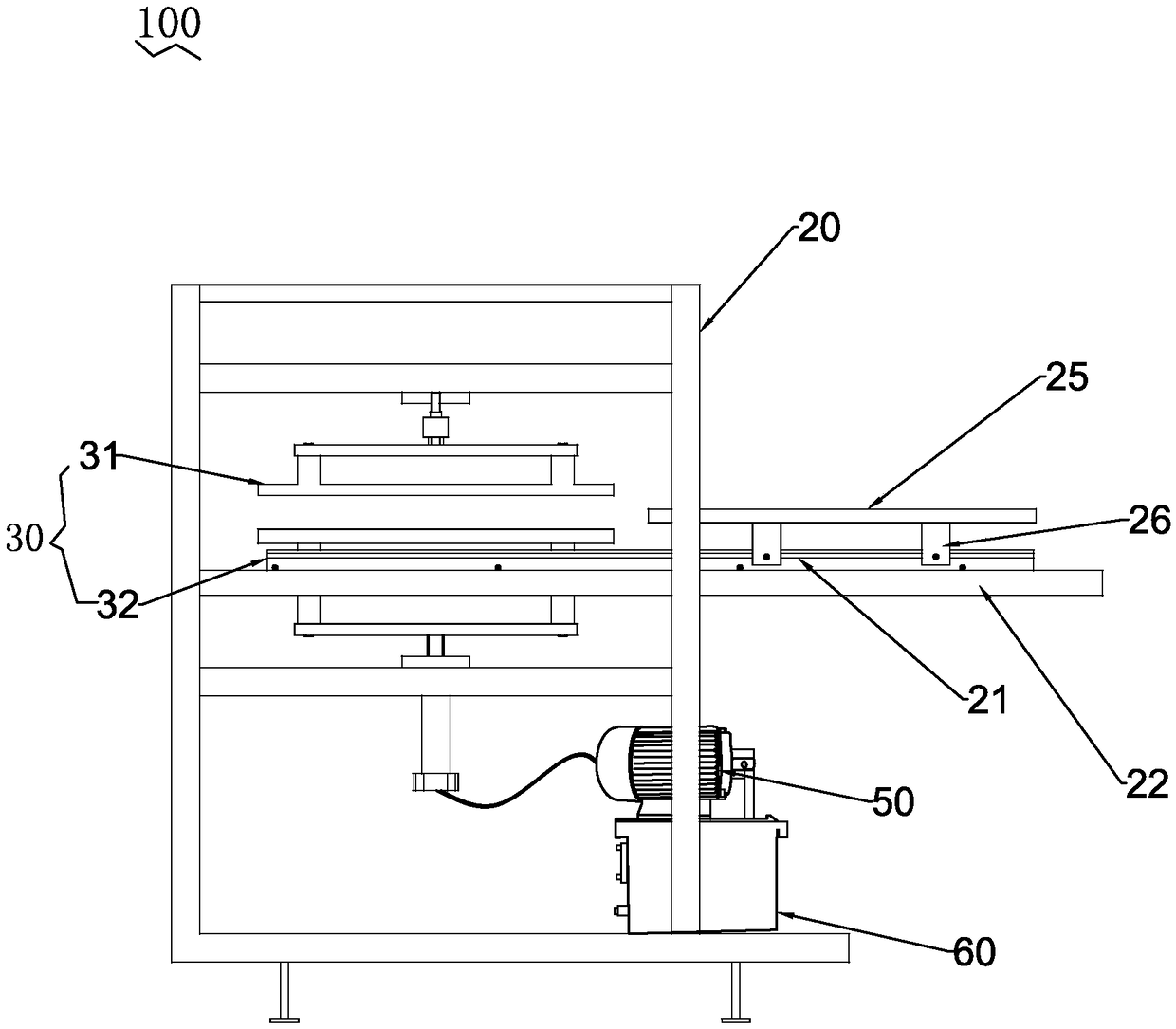

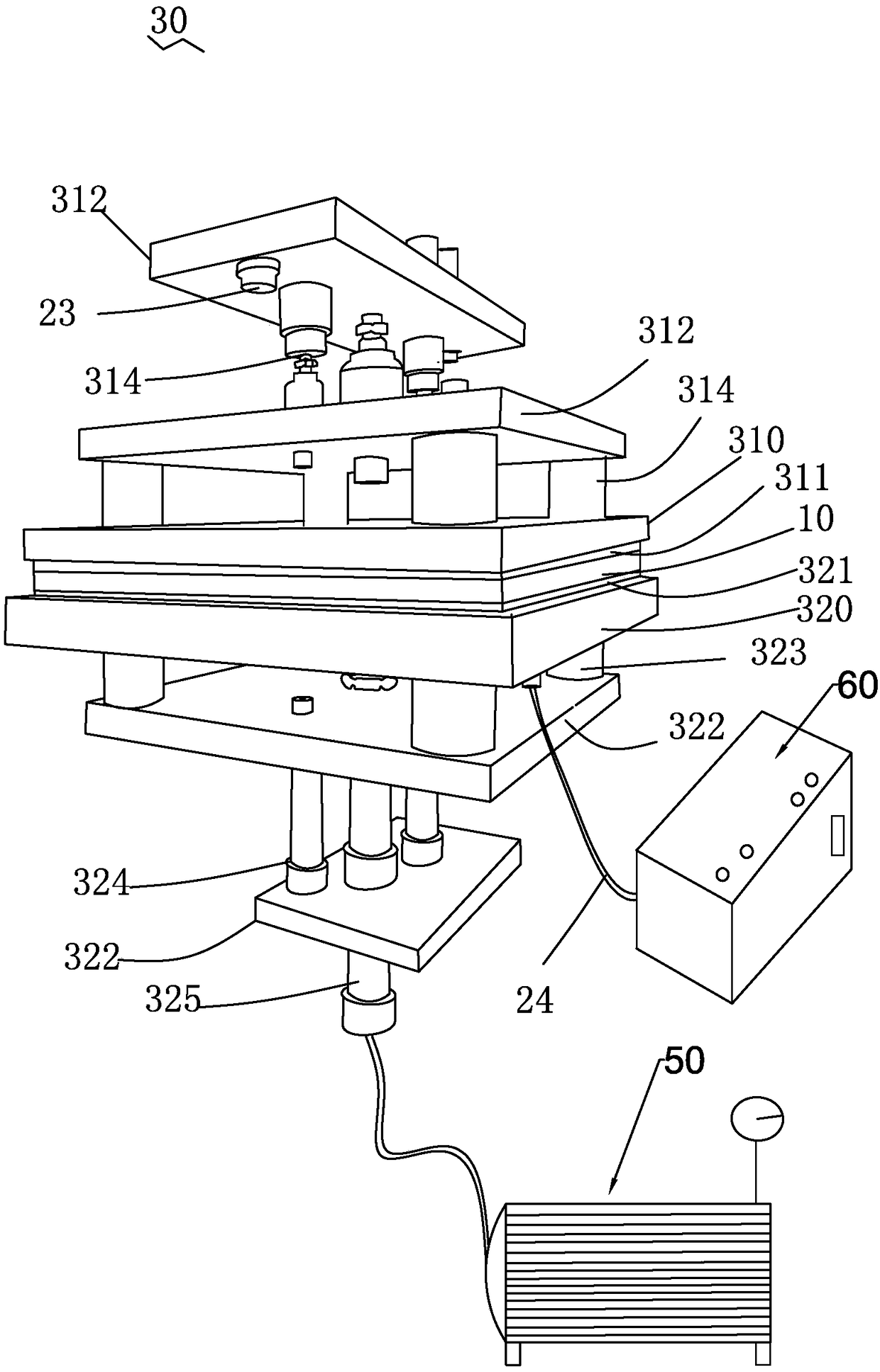

Screen pressing machine and screen pressing molding method

PendingCN108819447AReduce manual operationsIncrease productivityForme preparationHeat conductingEngineering

The invention relates to a screen pressing machine and a screen pressing molding method. The pressing machine comprises a frame and a pressing mechanism, the pressing mechanism comprises an upper heatconducting plate and a lower heat conducting plate, and the upper heat conducting plate and the lower heat conducting plate are oppositely arranged in a separation and reunion manner in order to press a screen. The screen is delivered to a position between the upper heat conducting plate and the lower heat conducting plate and undergoes hot pressing. The pressing machine and the pressing method can effectively reduce manual operation, improve the production efficiency, ensure the product quality, reduce wastes and reduce the material cost.

Owner:深圳市鑫联发丝印器材有限公司

Extraction method of tobacco cellulose based on ferric chloride pretreatment

InactiveCN102268827ALow dissolution rateReduce the impactPretreatment with acid reacting compoundsPulping with organic solventsDissolution reactionAqueous medium

The invention relates to a process for extracting cellulose from tobacco, specifically: a tobacco pretreatment method, which involves reacting the tobacco material with a ferric chloride solution with a concentration of 0.2-0.6 mol / L at a temperature of 120-140°C. In 20 minutes, the tobacco pretreatment liquid was obtained, washed to neutrality, filtered, and dried to obtain a neutral tobacco pretreatment material, adding 1-butyl-3-methylimidazolium chloride salt equivalent to 10-15 times the quality of tobacco, Carry out sufficient dissolution reaction at 80-100°C to obtain a reaction solution, conduct solid-liquid separation, take the liquid, the liquid is a cellulose solution, add an aqueous medium, stir for not less than 30 minutes, and then filter, and the obtained filter residue is Cellulose; or filter the tobacco pretreatment liquid to obtain a filtrate, adjust the pH value of the filtrate to 3.0-5.0, generate solid precipitation, and carry out liquid-solid separation, and the solid precipitation is hemicellulose; the present invention has low cost, High yield, green and environmental protection.

Owner:CHONGQING HENGYUAN JINTONG TECH

CO low temperature oxidation catalyst and its preparation process

InactiveCN1762587AHave substantive characteristicsHigh catalytic activityDispersed particle separationCatalyst activation/preparationInorganic saltsReaction temperature

The low-temperature oxidation catalyst with Co3O4 as constituent for carbon monoxide is prepared by: by cobalt inorganic salt as predecessor and weak base as precipitant and liquid-phase deposition or homogeneous precipitation method, controlling pH value as 6-10, reacting for 1-5h at 25-80Deg; filtering, cleaning, drying, and calcining. The product has high catalytic activity and stability, and fit to wide applying range as -78-100Deg, air speed 2500-20000h-1, and CO content 0.25-2.0%. This method is simple and low cost.

Owner:SHANXI UNIV

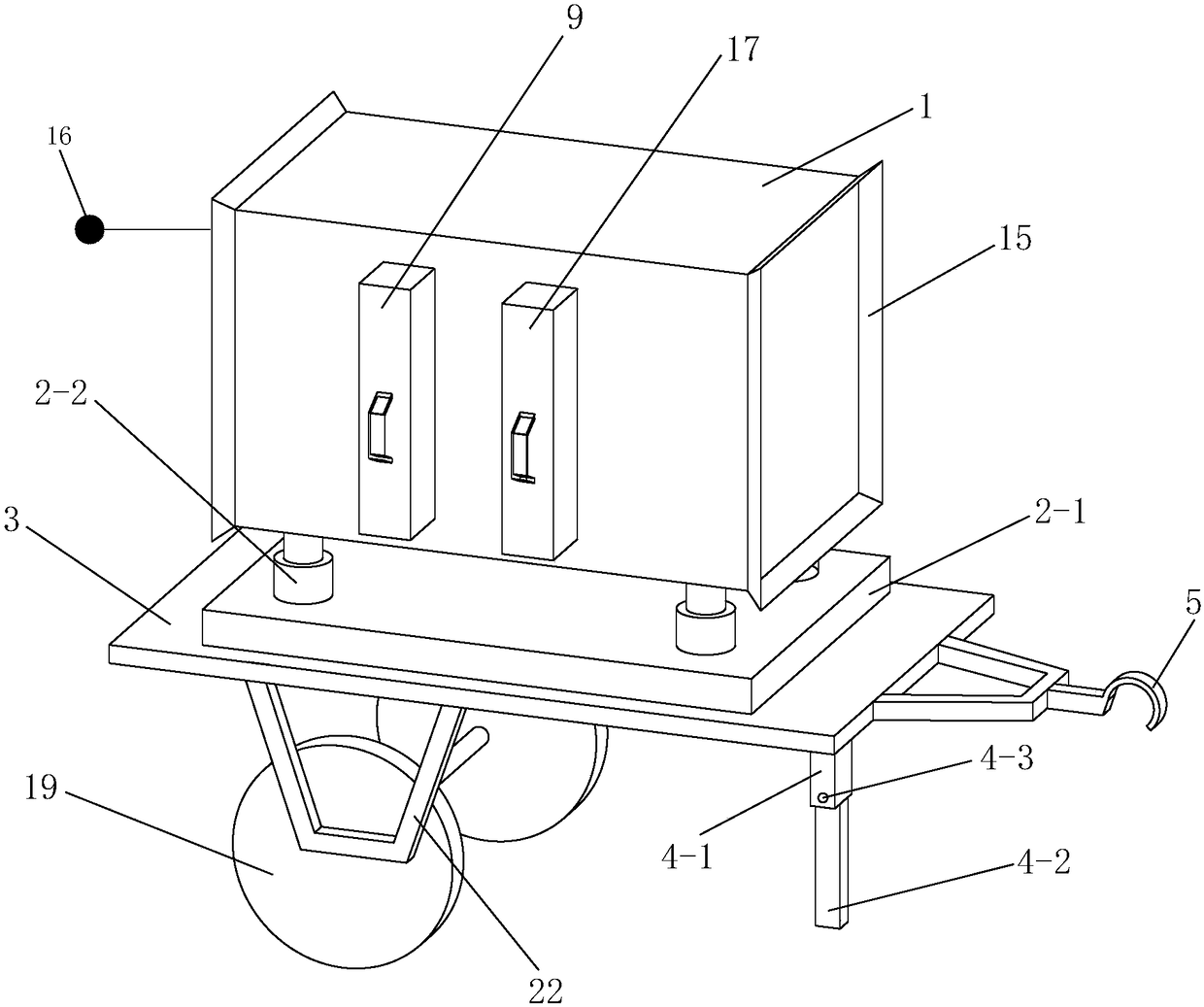

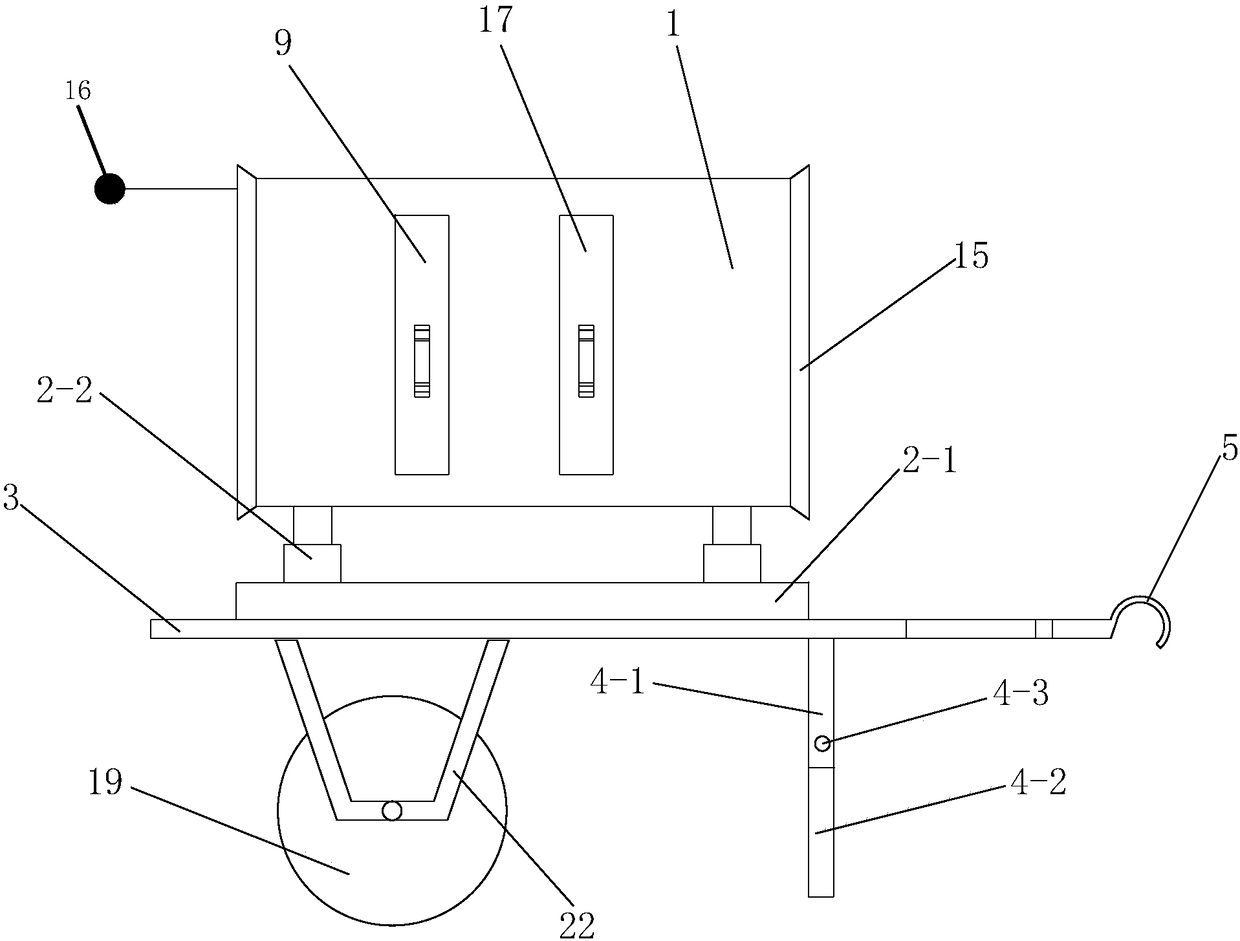

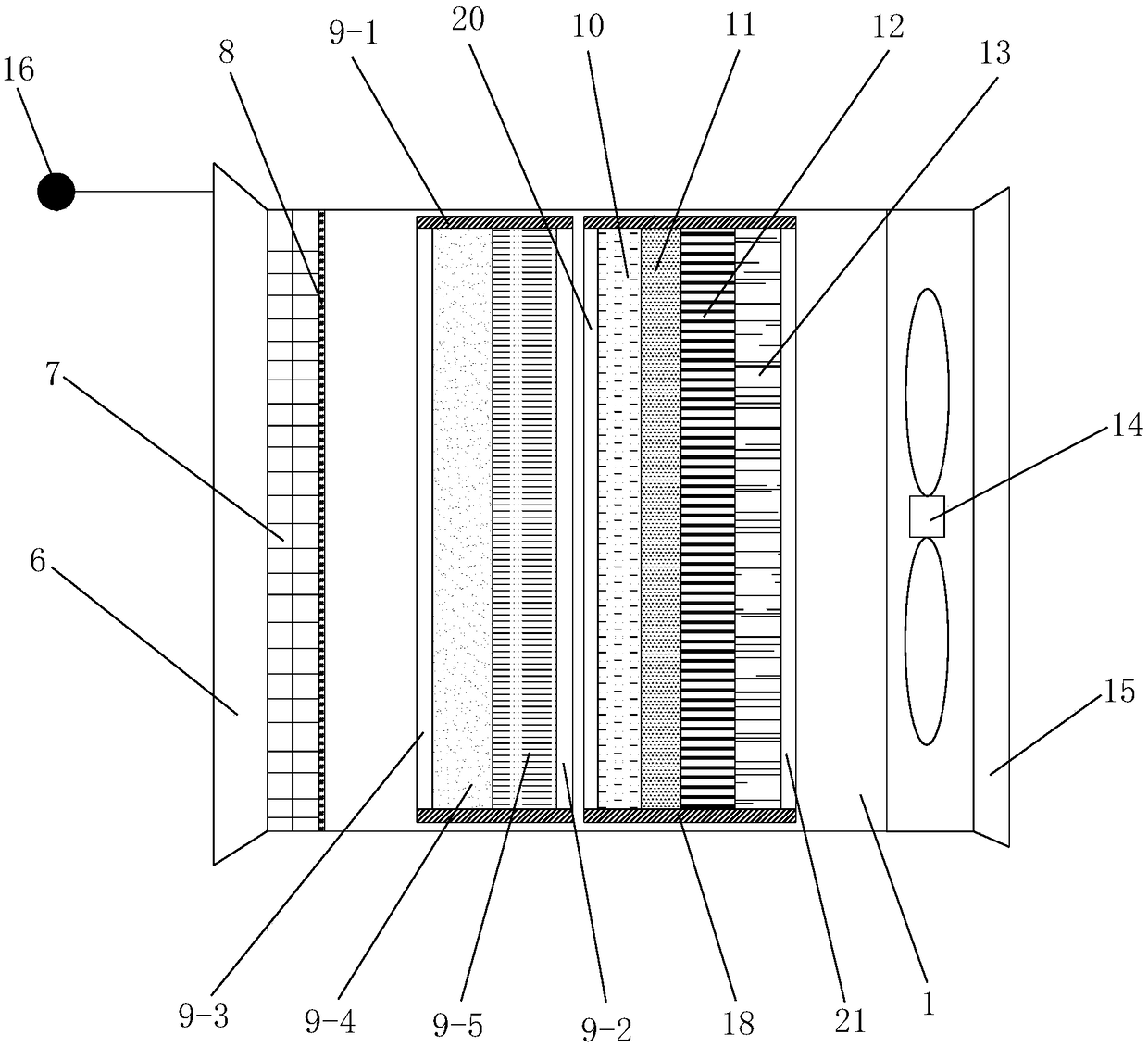

Movable mineral porous medium stage purification dust removing device and dust removing method

The invention discloses a movable mineral porous medium stage purification dust removing device. The movable mineral porous medium stage purification dust removing device comprises a movable mechanism, a lifting mechanism and a changeable porous medium stage purification main body; the lifting mechanism is arranged on the movable mechanism; the changeable porous medium stage purification main bodyis arranged on the lifting mechanism; the movable mechanism comprises a vehicle body; rubber wheels are arranged on the rear side of the bottom of the vehicle body; a telescopic support rod is arranged on the front side of the bottom of the vehicle body; the changeable porous medium stage purification main body comprises a casing; an air inlet is formed in the rear end of the casing; an air outlet is formed in the front end of the casing; a gas sensor is arranged at the air inlet; an air deflector, a dust retaining net, a replaceable prefiltering layer, a replaceable stage filtering layer anda fan are arranged in the casing from rear to front. The invention also provides a movable mineral porous medium stage purification dust removing method using the device. According to the movable mineral porous medium stage purification dust removing device and the movable mineral porous medium stage purification dust removing method disclosed by the invention, by adopting a dry type dust removing mode, the problem of forming a mud blockage filtering layer by wet dust removal is solved, and the demands of purification and dust removal of local air in an underground coal mine can be met.

Owner:XIAN UNIV OF SCI & TECH

Process for producing silicon rubber by using waste silicon rubber materials

The invention relates to a process for producing silicon rubber by using waste silicon rubber materials, which comprises the following steps: preparing dimethylsilane by using the waste silicon rubbermaterials through splitting, base-catalysed rearrangement, and discoloration and filtration of active carbon; and then placing the dimethylsilane, end-capping agent and tetramethylammonium hydroxideinto a kettle to prepare the silicon rubber. The process for producing silicon rubber by using waste silicon rubber materials comprises two additional process flows: 1) refining silicon dioxide from chemical waste residues generated in the process of preparing the silicon dioxide; and 2) finely preparing baking-free bricks by further utilizing the waste residues generated in the process of preparing the silicon dioxide, and adding coal ash, quartz sands, cement and rock sands into the waste residues. The process for producing silicon rubber by using waste silicon rubber materials prepares thesilicon dioxide and the baking-free bricks by using the waste silicon rubber materials, thereby having environmental protection value.

Owner:扬州宏远新材料股份有限公司

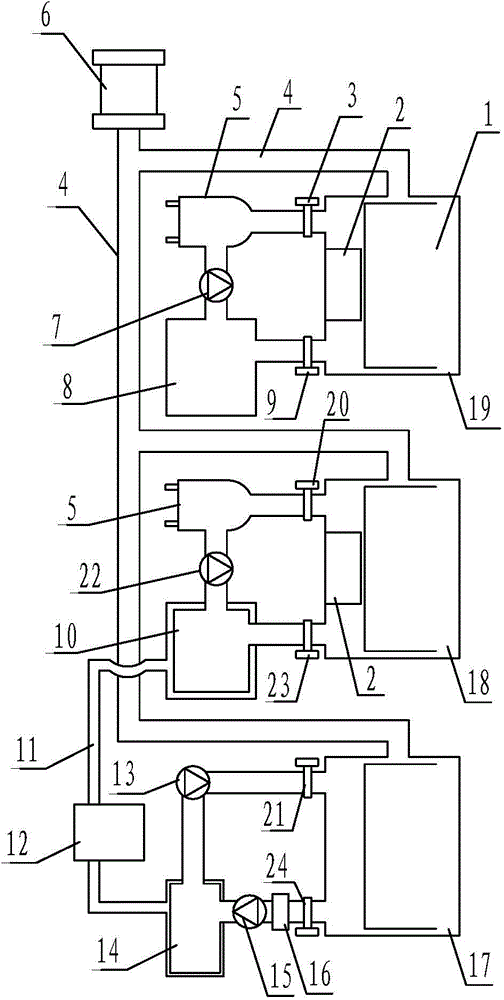

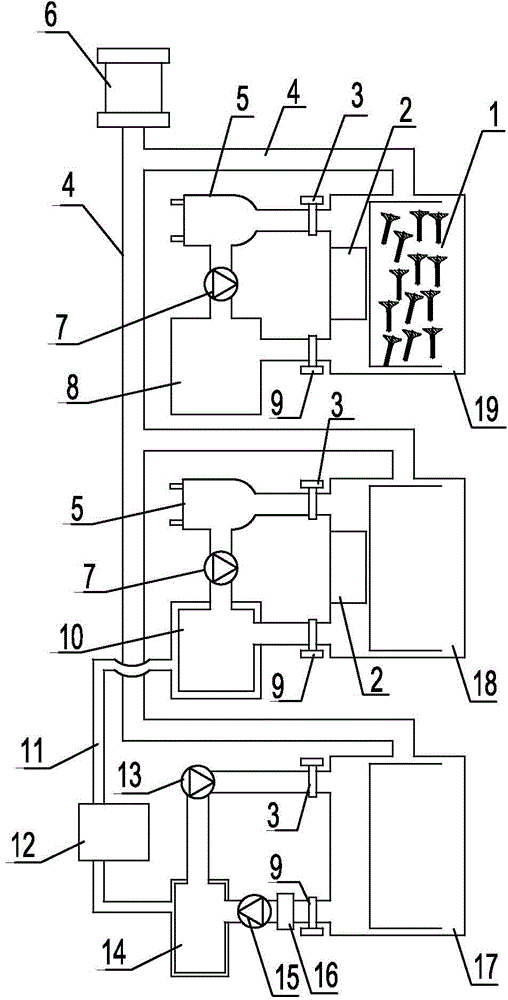

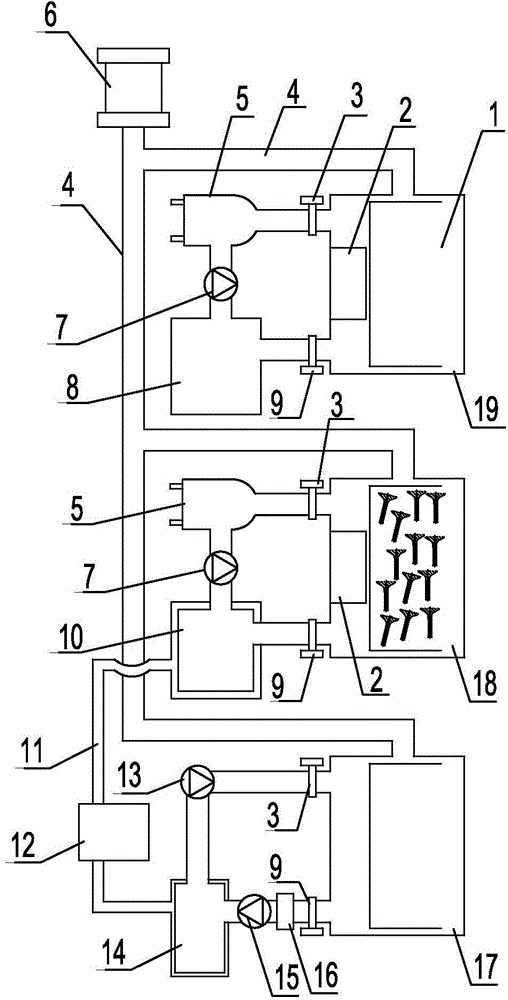

Surface and inner hole cleaning and drying equipment for hollow valves and using method thereof

ActiveCN104801512AEnable recyclingEasy to cleanDrying machines with local agitationDrying machines with materials at restHydrocarbon solventsMegasonic cleaning

The invention discloses surface and inner hole cleaning and drying equipment for hollow valves and a using method of the equipment. The equipment structurally comprises a coarse cleaning device, a fine cleaning device, a drying device, a vacuum pipeline, a vacuum pump, a steam pipeline and a steam generator, wherein the coarse cleaning device, the fine cleaning device and the drying device are connected through the vacuum pipeline, and the vacuum pump is arranged at one end of the vacuum pipeline. The cleaning and drying equipment can clean 1000 valves every time, a cleaning basket is put in a cleaning box to be automatically cleaned and dried, the cleaning and drying processes are carried out in a vacuum state, and ultrasonic cleaning is adopted in the cleaning process with a good cleaning effect. A cleaning solvent is a hydrocarbon solvent which can be recycled, so that the equipment is low in labor intensity.

Owner:济南沃德汽车零部件有限公司

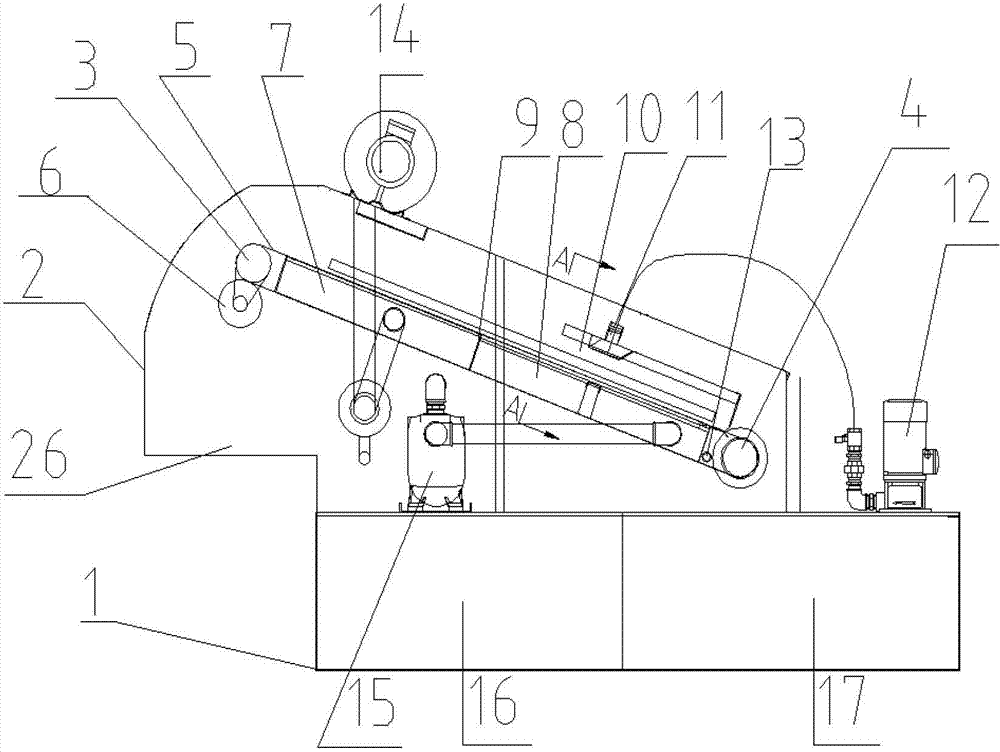

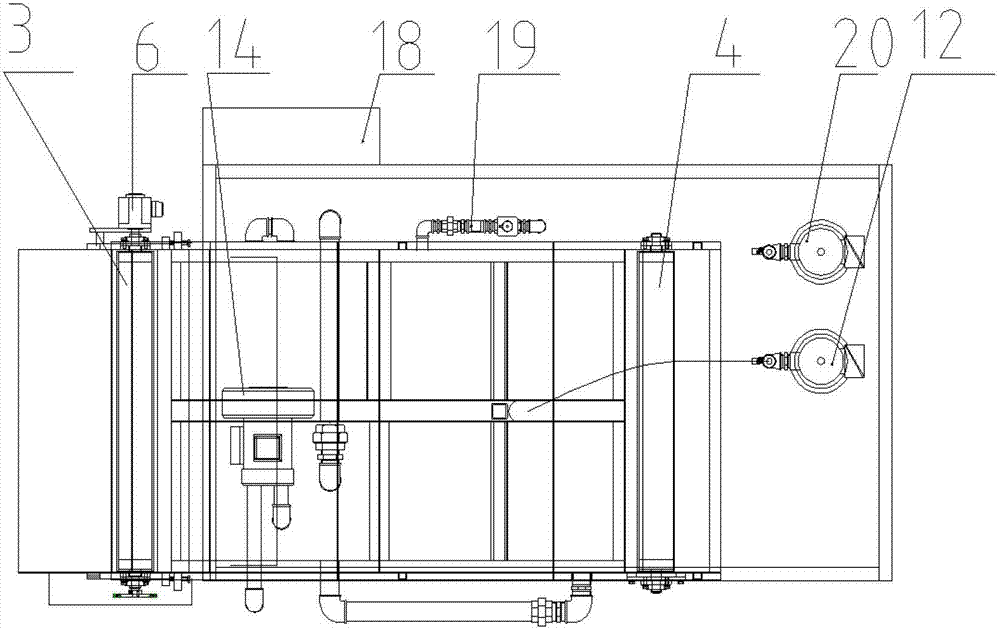

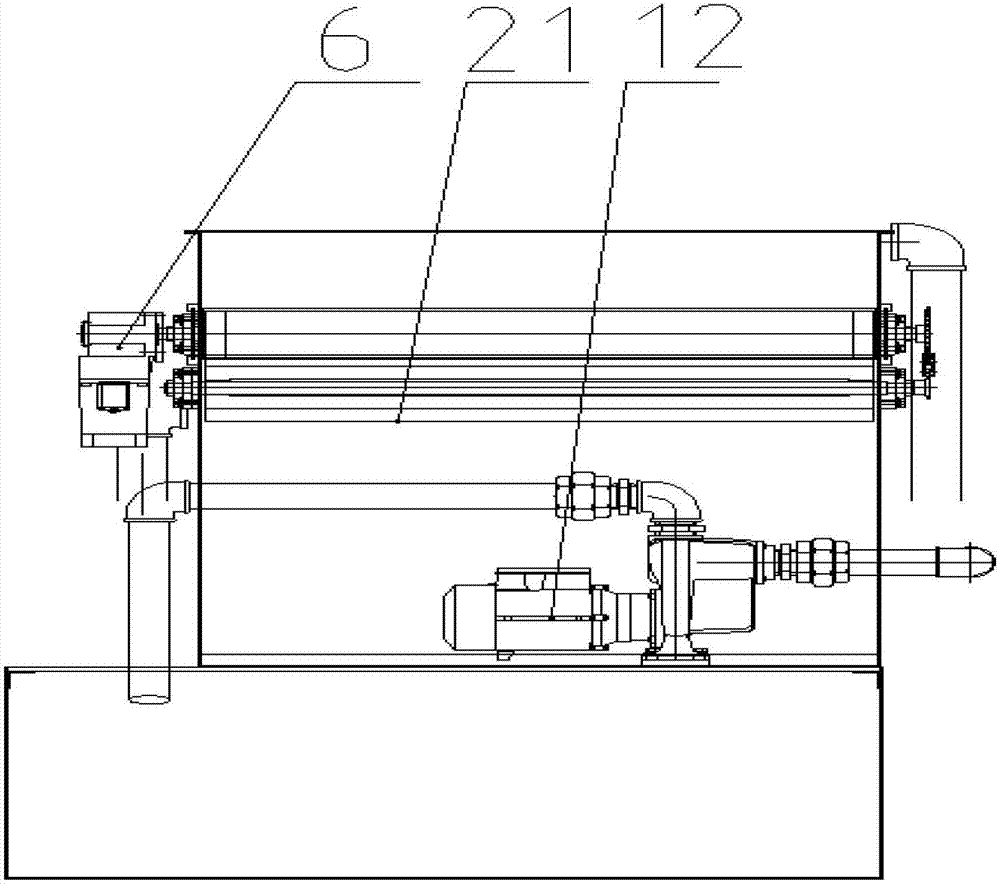

Sucking circulating belt type filtering device

The invention relates to the technical field of cutting liquid filtering equipment, in particular to a sucking circulating belt type filtering device. The device comprises a liquid box and a shell, wherein the shell is fixed on the liquid box; a driving roller is fixed at one end in the shell, and a driven roller is fixed at the other end in the shell; a filtering belt winds the driving roller and the driven roller; a control device and a drive motor are arranged on the side of the shell; the control device is connected with the drive motor, and the drive motor is connected with the driving roller; the upper layer of the filtering belt, the lower layer of the filtering belt and two sides of the shell define a cavity; the cavity is divided into a drying cavity and a sucking cavity by a partition plate; a gap plate is arranged on the lower part of the upper layer of the filtering belt; a filtering cavity is formed on the lower half part of the upper layer of the filtering belt, and a waste liquid inlet is formed in the filtering cavity; and a sucking pump is fixed on the liquid box and connected to a sucking cavity through a pipeline, and a negative pressure message-sending device which is arranged on the side of the shell is connected to the sucking cavity. By the device, the cutting liquid can be effectively filtered, the using cost of a machine tool is reduced, and automatic filtering is realized; and the device is easy to operate and convenient to maintain.

Owner:烟台开发区博森科技发展有限公司

Method for preparing magnetic nano-solid acid catalyst from biomass hydrolysis and liquefaction residues

ActiveCN103977820ALow priceSimple preparation processPhysical/chemical process catalystsHydration reactionCarbonization

The invention discloses a method for preparing a magnetic nano-solid acid catalyst from biomass hydrolysis and liquefaction residues. The method is characterized by comprising the following steps: preparation of a carbon-based material, preparation of a magnetic nano-carbon-based precursor, oxidation of the magnetic nano-precursor, carbonization reaction and sulfonation reaction. The catalyst can be used in hydrolysis reaction, esterification reaction, olefin hydration reaction, alkylation reaction, acetalization and ketalization reaction and the like. Compared with a conventional magnetic catalyst which is prepared by taking magnetic Fe3O4 particles as cores, the catalyst has the higher stability. Compared with a conventional carbon-based catalyst, magnetic particles contained in the catalyst are distributed in internal pores, so that the catalyst has the larger surface area for loading functionalized functional groups. The catalyst has the advantages that the preparation method is simple, the catalytic efficiency is high, the magnetic nano-particles are distributed uniformly, the specific surface area is large, the catalyst is easily separated from products, and the waste of resources is reduced; the method is one of methods for recycling the biomass hydrolysis and liquefaction residues.

Owner:吉林栩融科技有限公司

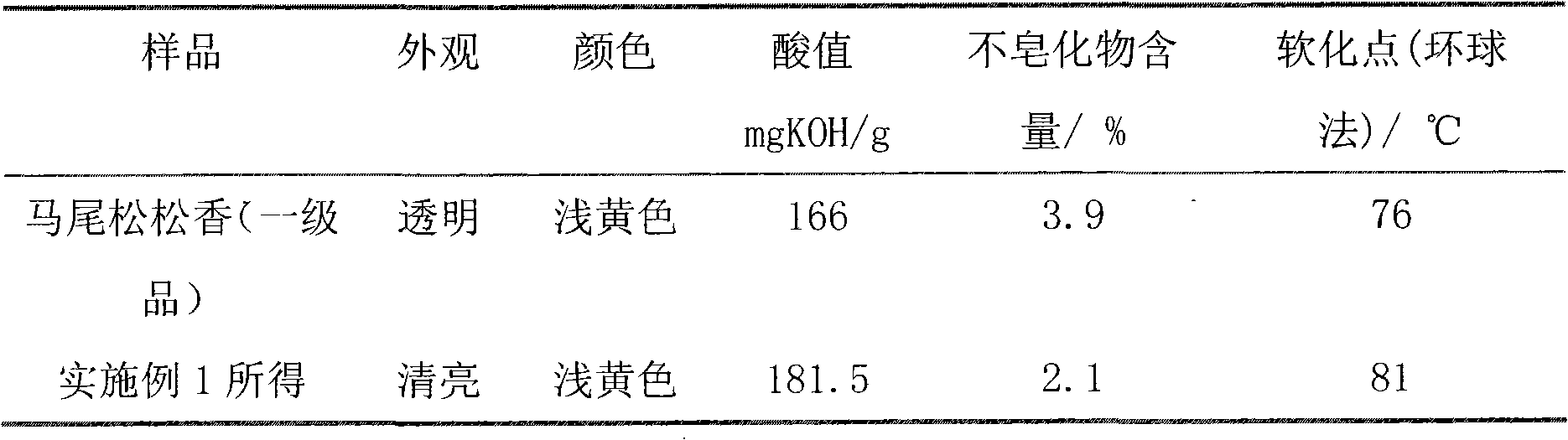

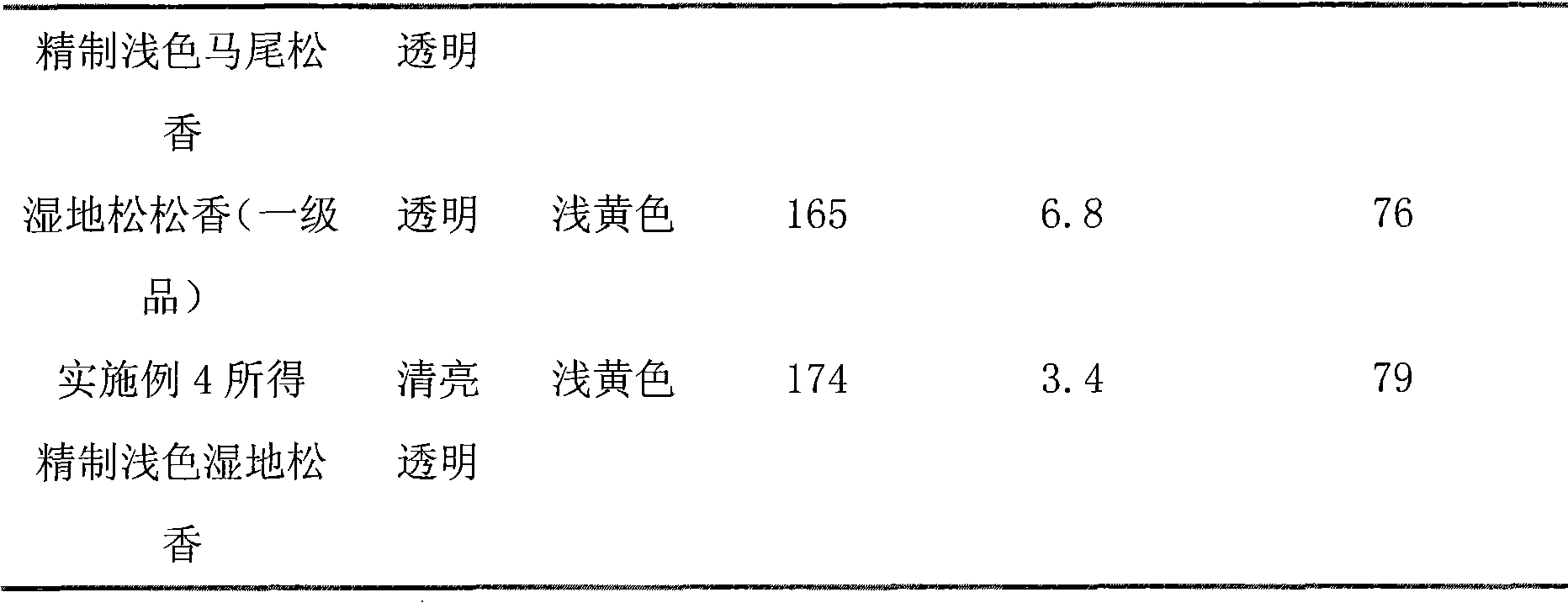

Method of refining and processing rosin

InactiveCN101665660AReduce consumptionThe method steps are simpleNatural resin purificationResin acidRoom temperature

The invention provides a method of refining and processing rosin, comprising the following steps: (1) dissolving rosin in dichloromethane, and filtering the solution of the rosin and the dichloromethane to remove the insoluble impurities; (2) adding acetonitrile to the solution of the rosin and the dichloromethane to precipitate resin acid, filtering the solution of the rosin and the dichloromethane, and collecting the precipitated resin acid; heating to distill filtrate, collecting the distillate formed blow 70 DEG C, recycling the dichloromethane, filtering and collecting part of resin acidwhich is precipitated after the residual filtrate is cooled to the room temperature; combining the filtrate, and then heating to distill the filtrate and recycle the dichloromethane; and (3) heating to melt the precipitated resin acid at normal pressure under the protection of N2 or CO2, and cooling the melted precipitated resin acid to obtain the refined rosin of light color, high acid value andlow unsaponifiable matter. The method of refining and processing rosin uses no special pressure resisting equipment, is easy to operate, has low production cost and is particularly suitable for industrial production.

Owner:GUANGXI UNIV FOR NATITIES

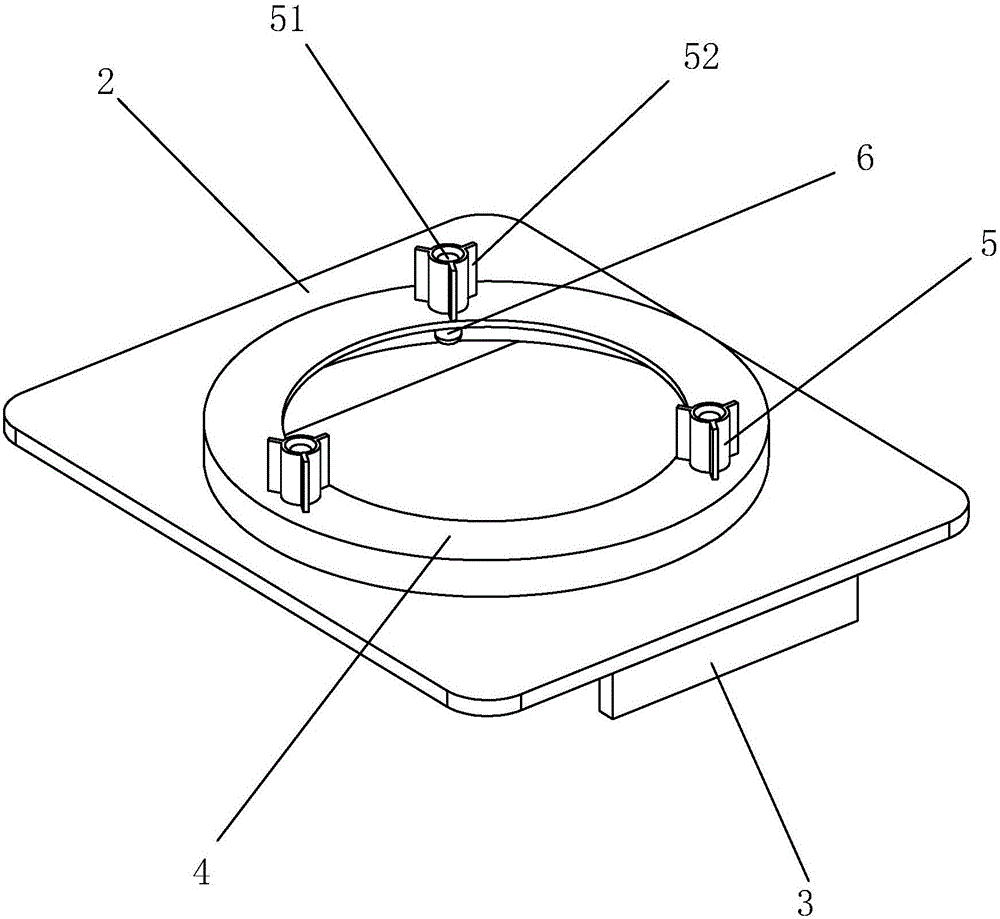

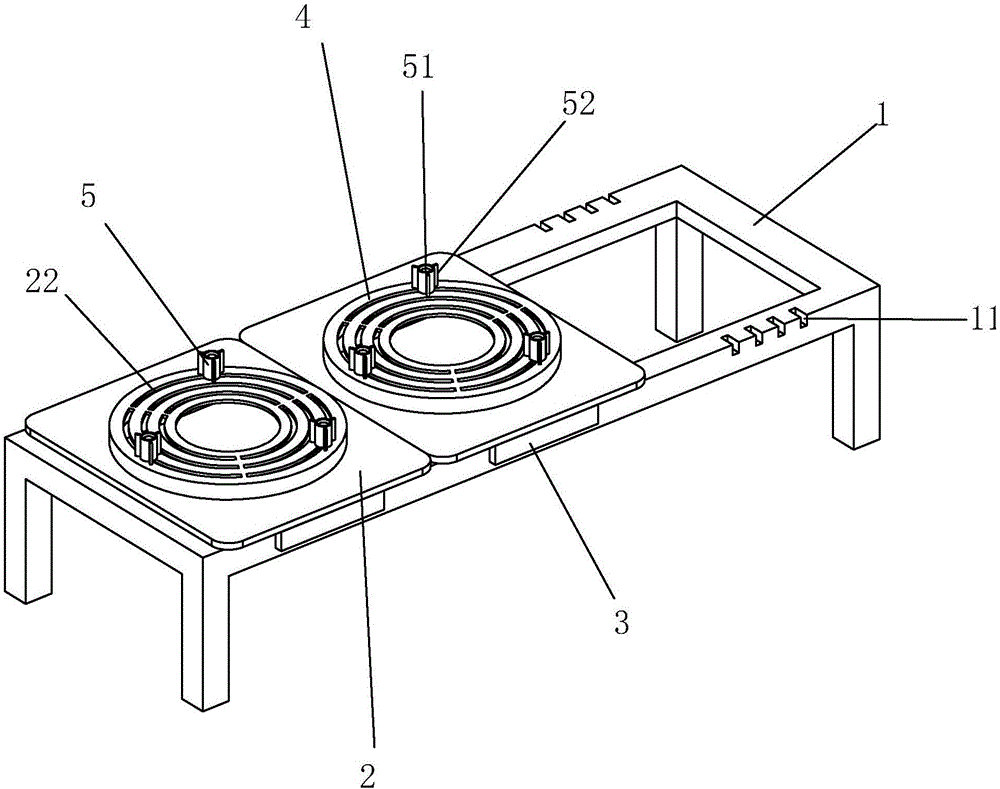

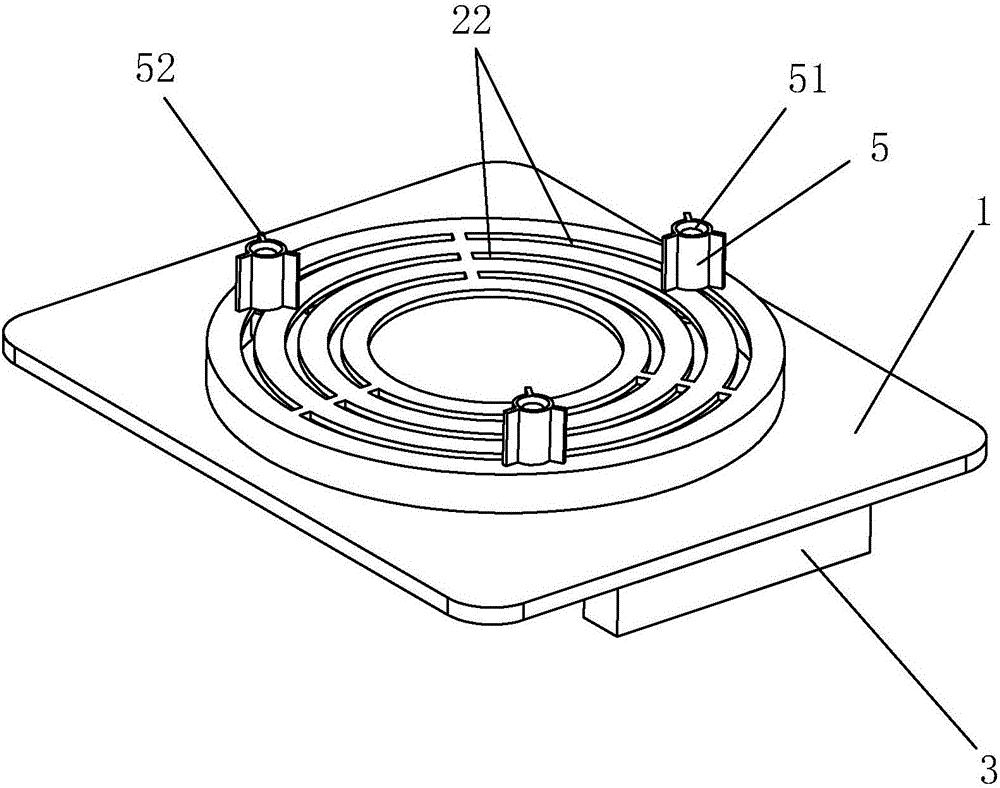

Paint spraying jig

ActiveCN106166524ARestricted degrees of freedomAchieve fixationSpraying apparatusDegrees of freedomEngineering

Owner:苏州瑞荣精密机械厂

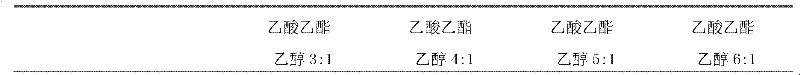

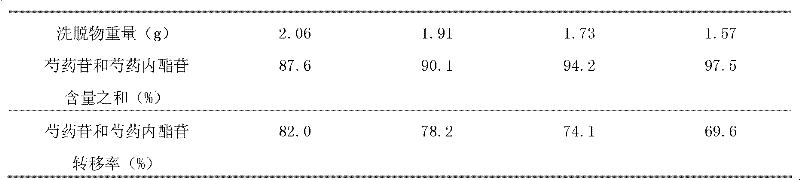

Method for preparing albiflorin and paeoniflorin

ActiveCN102304159ASimple and efficient operationContinuous productionSugar derivativesSugar derivatives preparationDrugSolvent

The invention relates to a method for preparing albiflorin and / or paeoniflorin. The method is characterized by comprising the following steps of: refining alumina with white peony total glucoside extract, wherein the white peony total glucoside extract is dissolved with water, and alumina is refined; refining the alumina refined solution with activated carbon; and refining the activated carbon refined substance with silica gel, wherein eluent which is 8 to 20 times that of activated carbon refined substance is added into the activated carbon refined substance for dissolving, passes through a silica gel column, and is eluted with eluent; fractions are collected and inspected by thin layers to collect fraction containing paeoniflorin, fraction containing paeoniflorin and albiflorin and fraction containing albiflorin respectively; all solvents are reclaimed; the extract is dissolved with appropriate water and filtered; and the filtrates are dried to respectively obtain the paeoniflorin, mixture of paeoniflorin and albiflorin, as well as the albiflorin. The mixture of paeoniflorin and albiflorin is refined repeatedly according to the performed method to obtain the paeoniflorin and the albiflorin. According to the product prepared by the method, the content of paeoniflorin is more than or equal to 95 percent, and the content of the paeoniflorin is more than or equal to 92 percent, which are in accordance with the standard of raw material drugs of the first type of new drug.

Owner:北京采瑞医药科技研究院有限公司

Preparation method of low-viscosity 107 silicone rubber

The invention belongs to the field of polysiloxane synthesis technologies, and particularly relates to a preparation method of low-viscosity 107 silicone rubber. According to the method, dimethyl dichlorosilane is hydrolyzed, an annulus body and a linear body are separated, carbonate is added into the separated-out linear body, temperature is raised to conduct reaction under negative pressure, the negative pressure is restored to normal pressure after viscosity reaches 300-1500 Pa.s, and low-molecular substances are drawn out through filtration to obtain the product. The viscosity of the prepared low-viscosity 107 silicone rubber is 300-1500 Pa.s and can be easily and accurately controlled, and reaction is mild. No low-molecular cyclosiloxane is generated in reaction, and the yield is greatly increased and reaches above 96%. A catalyst can be removed just through filtration and can also be recycled.

Owner:SHANDONG DONGYUE ORGANIC SILICON MATERIAL

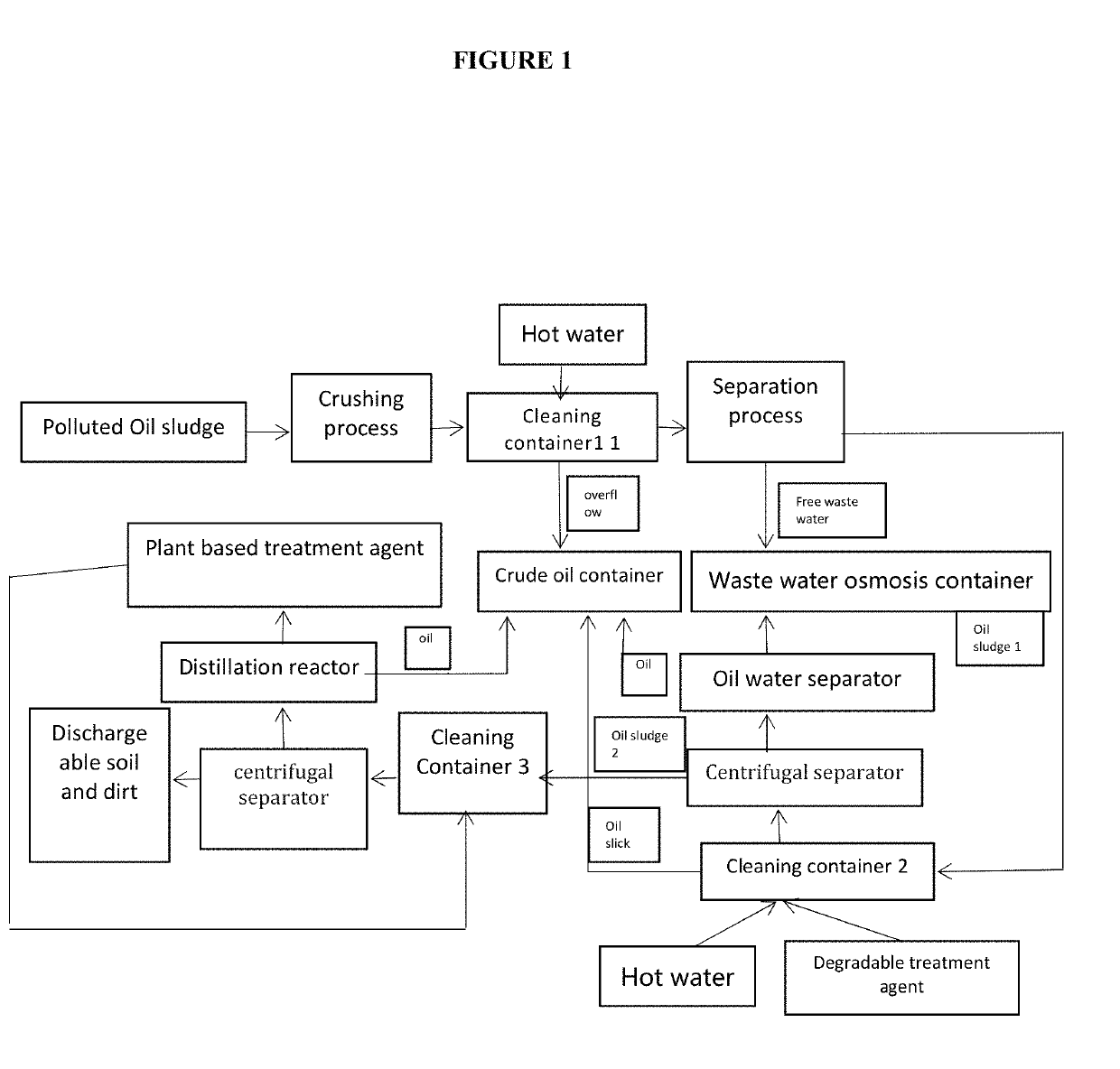

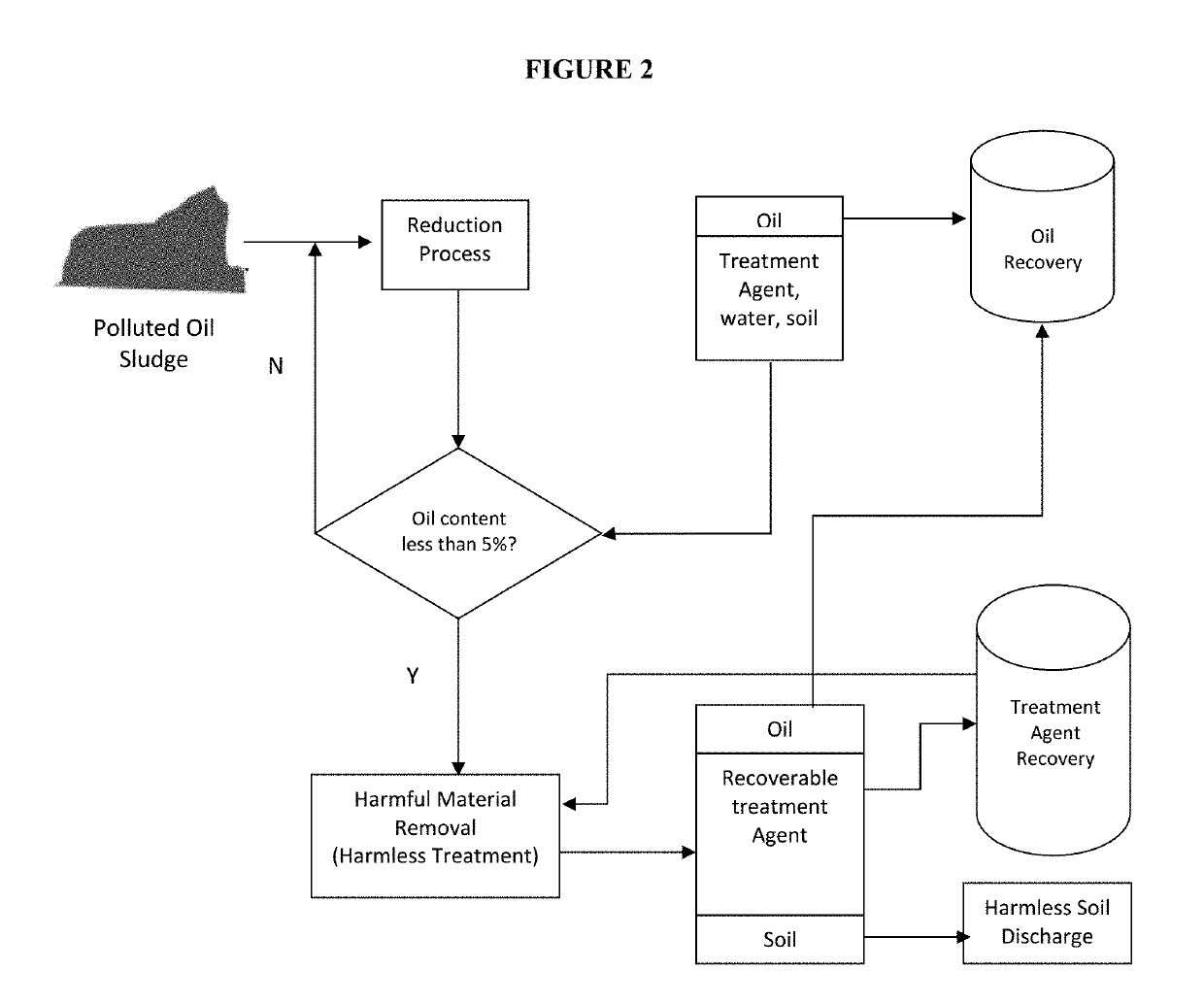

Treatment Process for Polluted Oil Sludge

InactiveUS20190300795A1Simple operationWide application rangeSludge treatment by de-watering/drying/thickeningWater treatment compoundsSolid phasesOil water

Treatment systems, agents and processes are described for processing polluted oil sludge into environmentally harmless and reusable resources. The oil sludge is first crushed, mixed with water, stirred, and stratified, then the overflow layer with the oil slick is transferred into oil recovery tank; the remaining mixture of solid and liquid is then subjected to centrifugal solid-liquid separation, the resulting free water is collected for reuse through osmosis, and the remaining solid phase material goes through a secondary oil content reduction treatment, adding water, degradable treatment agent, stirring, and after the system was standing stratified, the upper layer with the oil slick is overflowed and transferred to oil recovery tank; for the mixture from the centrifugation separation and reduction treatment processes, the resulting liquid phase is subjected to oil water separation, the oil phase is transferred into the oil recovery tank, the water phase enters into the wastewater recycling tank for recycle and reuse, the remaining solid phase is treated to become environmentally harmless materials; undergo centrifugal separation again, and the liquid phase is distilled to recover the plant based treatment agent, the remaining oil is transferred to the oil recovery tank, and the excess sludge is dried.

Owner:REN HANG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com