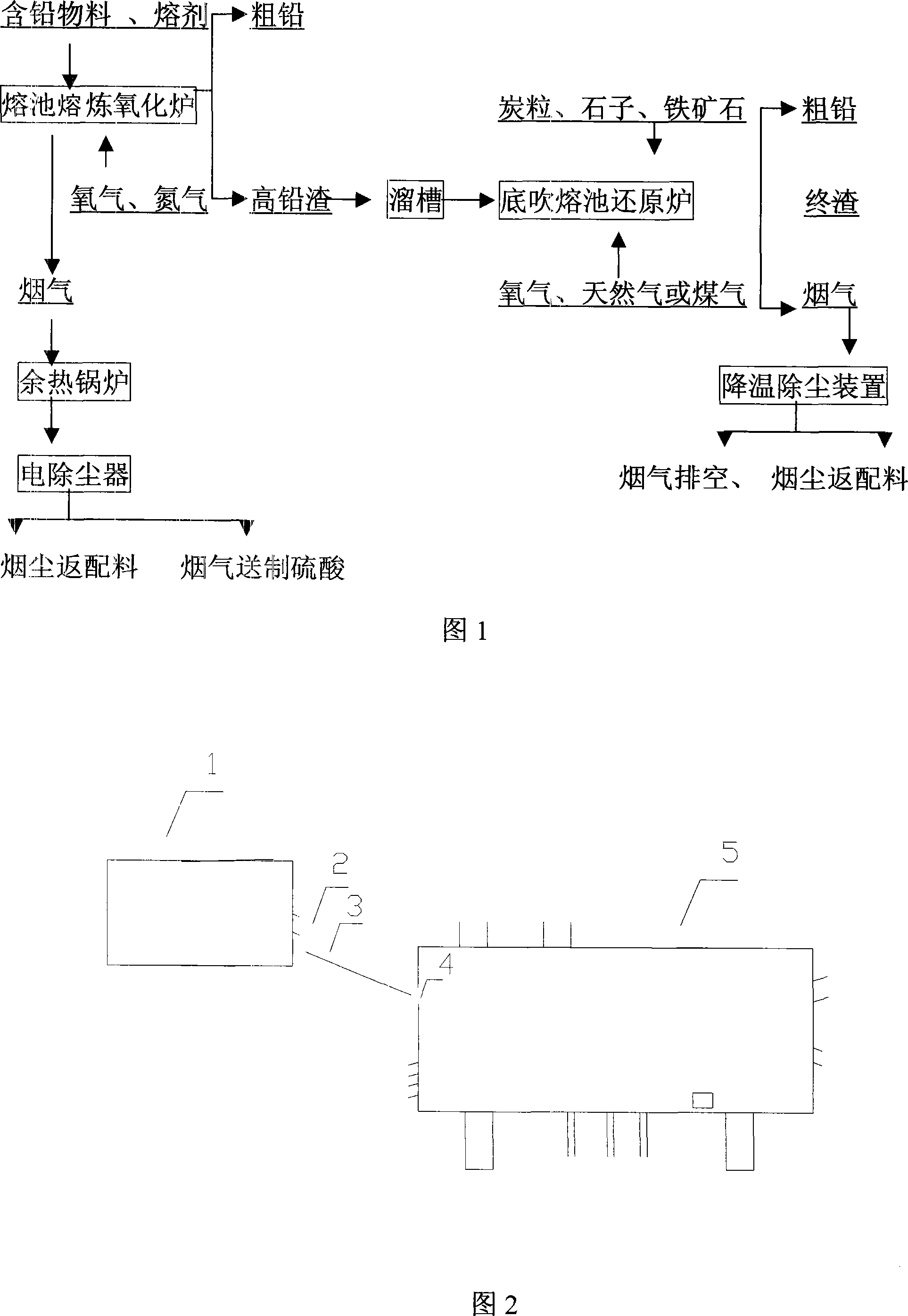

Direct lead smelting method in molten pool and its device

A technology for molten pool smelting and lead smelting, which is applied in the field of lead smelting, can solve the problems of poor environment, low heat utilization rate and high energy consumption, and achieves the effects of low smoke and dust rate, improved heat utilization rate, and improved reduction degree.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this embodiment, the composition of the high-lead slag entering the bottom-blown molten pool reduction furnace is as follows: PbO: 50%, FeO: 12% SiO 2 : 10%, CaO: 5%, ZnO: 7% Cu: 1%, S: 0.6%, As: 0.4%, Sb: 0.5%.

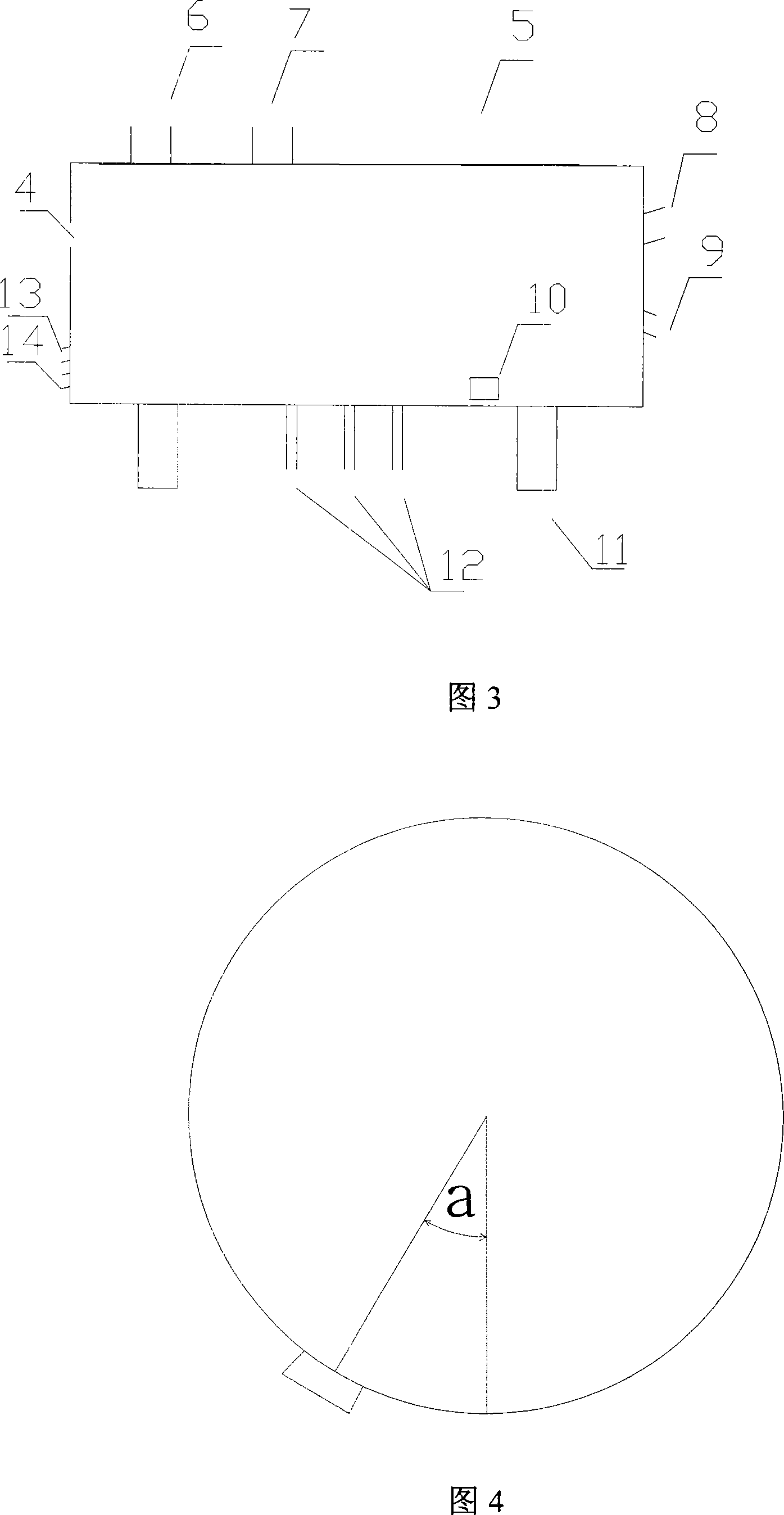

[0039] The high-lead slag melt produced by the molten pool smelting oxidation furnace flows into the bottom-blown molten pool reduction furnace through the chute, and carbon particles, stones and iron ore are added from the feeding port in the bottom-blown molten pool reduction furnace, and the particle size of the carbon particles is 10-70mm, the amount of carbon particles per ton of high-lead slag is 20-100Kg, the particle size range of stones and iron ore is required to be 2-5mm, and the amount meets Fe / SiO 2 =1~1.4 / 1, CaO / SiO 2 =0.4~0.7 / 1 range requirement. At the same time, oxygen and natural gas are supplied through the gas spray gun at the bottom or bottom side of the bottom-blown molten pool reduction furnace, and the oxygen consumption per ton of...

Embodiment 2

[0041] In the present embodiment, the composition of the high-lead slag entering the bottom-blown molten pool reduction furnace is as follows:

[0042] PbO: 50%, FeO: 12% SiO 2 : 10%, CaO: 5%, ZnO: 7% Cu: 1%, S: 0.6%, As: 0.4%, Sb: 0.5%.

[0043] The high-lead slag melt produced by the molten pool smelting furnace flows into the bottom-blown molten pool reduction furnace through the chute, and carbon particles, stones and iron ore are added from the feeding port in the bottom-blown molten pool reduction furnace, and the particle size of the carbon particles is 10 ~70mm, the amount of carbon particles per ton of high-lead slag is 0~100Kg, the particle size range of stones and iron ore is required to be 2~5mm, and the amount meets Fe / SiO 2 =1~1.4 / 1, CaO / SiO 2 =0.4~0.7 / 1 range requirement. At the same time, oxygen and gas are supplied through the gas spray gun at the bottom or bottom side of the bottom-blown molten pool reduction furnace, and the oxygen consumption per ton of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com