Method for extracting iron-copper alloy from high-temperature molten copper slag

A high-temperature melting, iron-copper alloy technology, applied in the field of resources and the environment, can solve the problems of high energy consumption, increased energy consumption, and increased costs, and achieve the effects of high economic value, simple process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

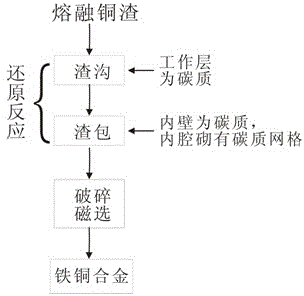

[0029] Example 1 A method for extracting iron-copper alloys from high-temperature molten copper slag, the process flow can refer to the attached figure 1 , the high-temperature molten copper slag from the copper smelting furnace flows through the copper slag tank with reducing function, and then directly flows into the copper slag bag with reducing function to carry out the reduction reaction. After the slag bag is cooled, it is crushed and magnetically separated to obtain Iron copper alloy.

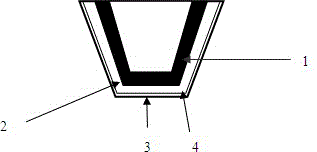

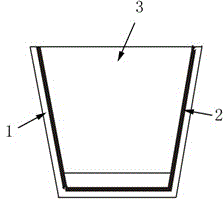

[0030] The structure of the copper slag tank with reducing function can refer to the attached figure 2 , A layer of coke bricks with a thickness of 200 mm is built on the working layer of the copper slag tank, a layer of magnesia-chrome castable with a thickness of 200 mm is cast on the permanent layer, and a 10 mm-thick nano-insulation board is used for the heat insulation layer. In this way, the temperature of the steel shell is 45°C. Subsequent magnetic separation of metal iron i...

Embodiment 2

[0033] Example 2 A method for extracting iron-copper alloys from high-temperature molten copper slag. The high-temperature molten copper slag coming out of a copper smelting furnace flows through a copper slag tank with a reduction function, and then directly flows into a copper slag bag with a reduction function for a reduction reaction. When the slag After the bag is cooled, it is crushed and magnetically separated to obtain the iron-copper alloy.

[0034] The structure of the copper slag tank with reducing function can refer to the attached figure 2 , A layer of coke bricks with a thickness of 200 mm is built on the working layer of the copper slag tank, a layer of magnesia-chrome castable with a thickness of 200 mm is cast on the permanent layer, and a 10 mm-thick nano-insulation board is used for the heat insulation layer. In this way, the temperature of the steel shell is 45°C. Subsequent magnetic separation of metal iron increased by 10%.

[0035] The copper slag p...

Embodiment 3

[0037] Example 3 A method for extracting iron-copper alloys from high-temperature molten copper slag. The high-temperature molten copper slag coming out of a copper smelting furnace flows through a copper slag tank with a reduction function, and then directly flows into a copper slag bag with a reduction function for a reduction reaction. When the slag After the bag is cooled, it is crushed and magnetically separated to obtain the iron-copper alloy.

[0038] The structure of the copper slag tank with reducing function can still refer to the attached figure 2 , but different from Example 1, a layer of carbonaceous ramming material with a thickness of 250 mm is built on the working layer of the copper slag tank, a layer of aluminum-silicon castable with a thickness of 200 mm is cast on the permanent layer, and the heat insulation layer Using 20 mm thick silicon calcium insulation board. In this way, the temperature of the steel shell is 40°C. Subsequent magnetic separation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com