Mine Cooling System Using Ice Slurry Cold Storage Technology for Secondary Side Fluid

A process technology and secondary side technology, which is applied in mining equipment, household refrigeration equipment, ventilation of mines/tunnels, etc., can solve problems such as the impact of project progress, high energy consumption in operation, and long laying distance of cold water pipelines, etc., to achieve solid Durable downhole protection, high heat transfer and flow characteristics, good downhole protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with examples.

[0020] The invention is used for the secondary side fluid of the high temperature heat damage in the underground mining working face of coal mines and non-coal mines. The ice slurry cold storage mine cooling system is used. The detailed process of the invention is as follows:

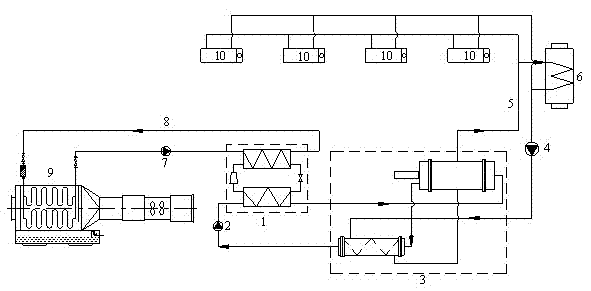

[0021] The low-temperature screw ethylene glycol unit 1 lowers the temperature of the primary refrigerant (35% ethylene glycol solution) to -10°C, and the primary refrigerant pump 2 sends 35% ethylene glycol into the ice slurry preparation device 3, through In the ice slurry production device 3, the primary refrigerant exchanges heat with the secondary refrigerant containing additives that hinder the growth of ice crystals and has antifreeze properties, and generates soft and fluffy ice crystal particles on the tube wall, and the ice crystal particles are removed by the polyurethane reciprocating scraping devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com