Production method of dihydrolaurenol by adopting mechanical steam re-compression

A technology of dihydromyrcenol and dihydromyrcene, which is applied in the production field of dihydromyrcenol, and can solve the problems of large consumption of refrigerant and heat medium in the condenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

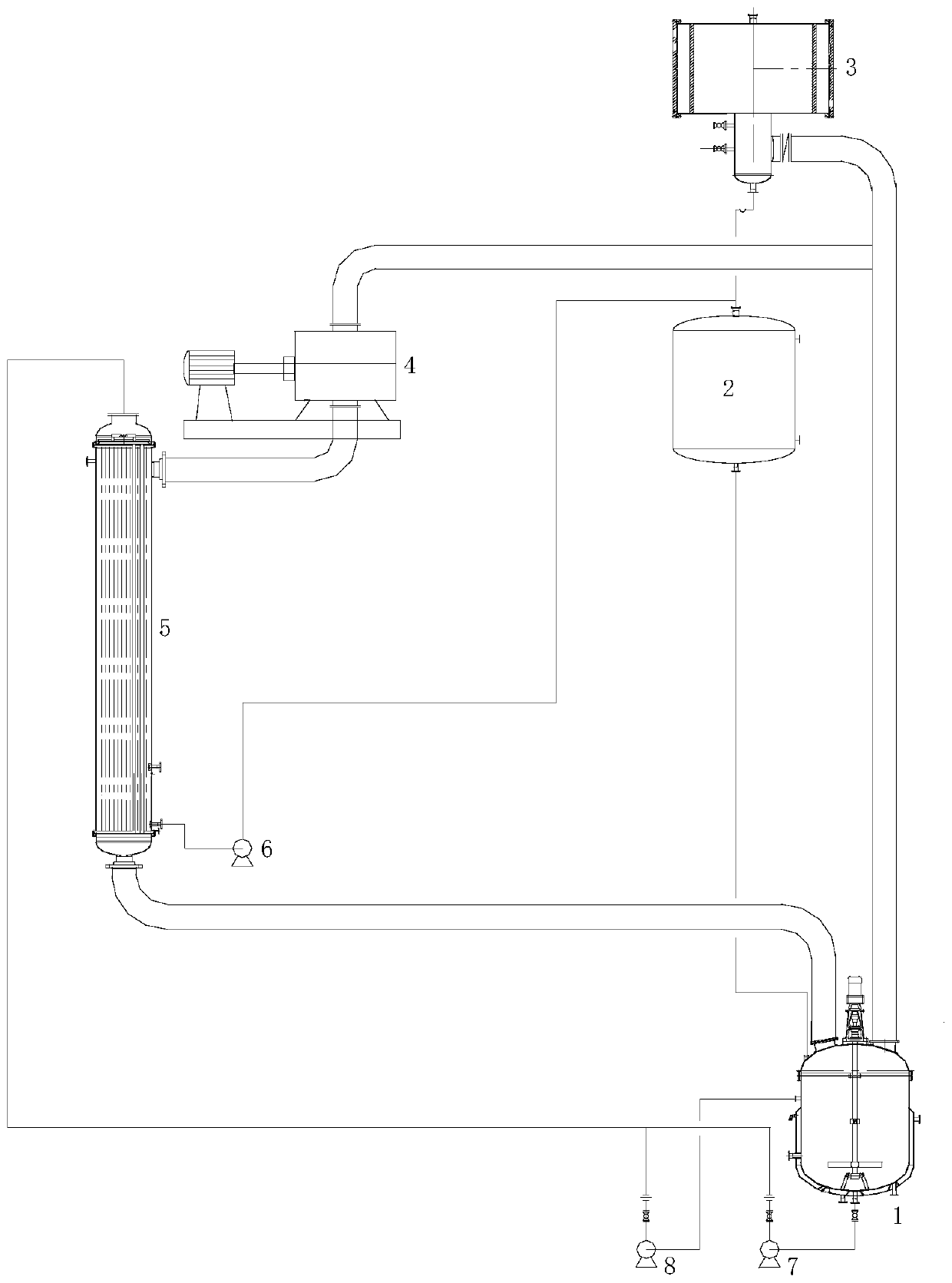

Embodiment 1

[0033] Dihydromyrcene, water and acetone are poured into the reaction kettle 1 at a ratio of 1:1:2. After starting the stirring, turn on the steam to heat. When the temperature reaches 80°C, the azeotrope is vaporized, and enters the compressor 4 through the conduit, and the compressor 4 The inlet pressure is 101kPa, start the compressor 4, adjust the frequency of the compressor 4 to 33, so that the outlet pressure is stable at 170kPa, after pressurization, the gas enters the falling film evaporator from the air duct 5, the inlet of the shell side, and the materials in the reactor 1 start the first The material circulation pump 6 and the second material circulation pump 7 circulate, the circulation volume is controlled at 1:1.5, and the temperature difference of the falling film heat exchanger 5 is 5°C. After the vapor-liquid two-phase is heat-exchanged by the condenser 3, the gas phase is condensed and then the third material is used The circulating pump 8 is driven into the c...

Embodiment 2

[0035] Dihydromyrcene, water, and methanol are poured into the reaction kettle 1 in a ratio of 1:1:2. After starting the stirring, turn on the steam to heat. When the temperature reaches 80°C, the azeotrope is vaporized, and enters the compressor 4 through the conduit, and the compressor The inlet pressure is 101kPa, start the compressor 4, adjust the frequency of the compressor 45, so that the outlet pressure is stable at 200kPa, after pressurization, the gas enters the inlet of the shell side of the falling film heat exchanger 5 from the gas guide pipe, and the first material of the reactor is started The circulation pump 6 and the second material circulation pump 7 circulate, the circulation volume is controlled at 1:1.5, and the temperature difference of the falling film heat exchanger 5 is 6.1°C. After the gas-liquid two-phase heat exchange through the condenser 3, the gas phase is condensed and then the third material is used The circulating pump 8 is driven into the cataly...

Embodiment 3

[0037] Dihydromyrcene, water, and tetrahydrofuran are poured into the reaction kettle 1 at a ratio of 1:1:2. After starting the stirring, turn on the steam to heat. When the temperature reaches 80°C, the azeotrope is vaporized and enters the compressor 4 through the conduit. The compressor The inlet pressure of 4 is 101kPa, start compressor 4, adjust the frequency of compressor 4 to 35, so that the outlet pressure is stable at 170kPa, after pressurization, the gas enters the shell side inlet of falling film heat exchanger 5 from the air guide pipe, and the material of reactor 1 starts The first material circulation pump 6 and the second material circulation pump 7 circulate, the circulation volume is controlled at 1:2, and the temperature difference of the falling film heat exchanger 5 is 4.7°C. After the vapor-liquid two-phase is heat-exchanged by the condenser 3, the gas phase is condensed and used The 3rd material circulation pump 8 is driven into catalytic bed 2, and the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com