Cleaning method and equipment of spinneret plate for polyacrylonitrile fiber

A technology of polyacrylonitrile and spinneret, applied in the direction of spinneret assemblies, chemical instruments and methods, detergent compositions, etc., can solve the problems of restricting fiber quality, long cleaning time, increasing the amount of raw silk, etc. To achieve the effect of increasing the probability of collision, reducing cleaning time and facilitating operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

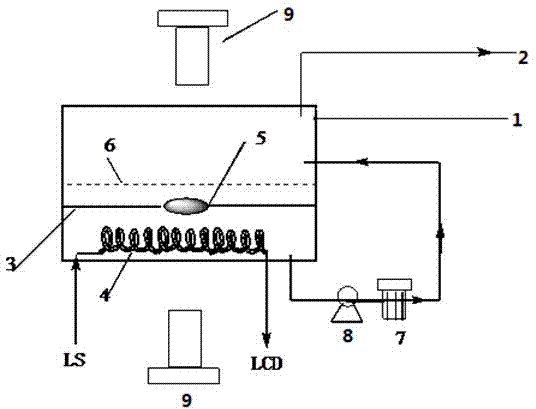

Method used

Image

Examples

Embodiment 1

[0028] Fix the spinneret on the spinneret holder, add 10% NaOH aqueous solution to pure dimethyl sulfoxide, control the pH value of the cleaning solution to 12, heat the cleaning solution to 50°C, turn on the circulation pump, and circulate and filter The system uses a 3um metal filter rod to filter, the vacuum degree is controlled at -100KPa, the ultrasonic device is turned on and the frequency is controlled at 25KHz, and the cleaning time is 2h.

[0029] After cleaning, the surface of the spinneret was smooth without corrosion, and the plugging rate of each spinneret hole was 0%.

Embodiment 2

[0031] Fix the spinneret on the spinneret holder, add KOH solution with a mass concentration of 1,5% to pure dimethyl sulfoxide, control the pH value of the cleaning solution to 14, heat the cleaning solution to 40°C, and turn on the circulation pump , The circulating filtration system uses a 5um metal filter rod for filtration, the vacuum degree is controlled at -90KPa, the ultrasonic device is turned on and the frequency is controlled at 25KHz, and the cleaning time is 2.5h.

[0032] After cleaning, the surface of the spinneret was smooth without corrosion, and the plugging rate of each spinneret hole was 0%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com