Sucking circulating belt type filtering device

A technology of filter device and circulating belt, applied in the direction of filtration and separation, moving filter element filter, separation method, etc., can solve the problems of inconvenient maintenance, difficult disassembly, and inability to continuously circulate and filter, and achieve convenient maintenance, reduce losses, Simple to use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

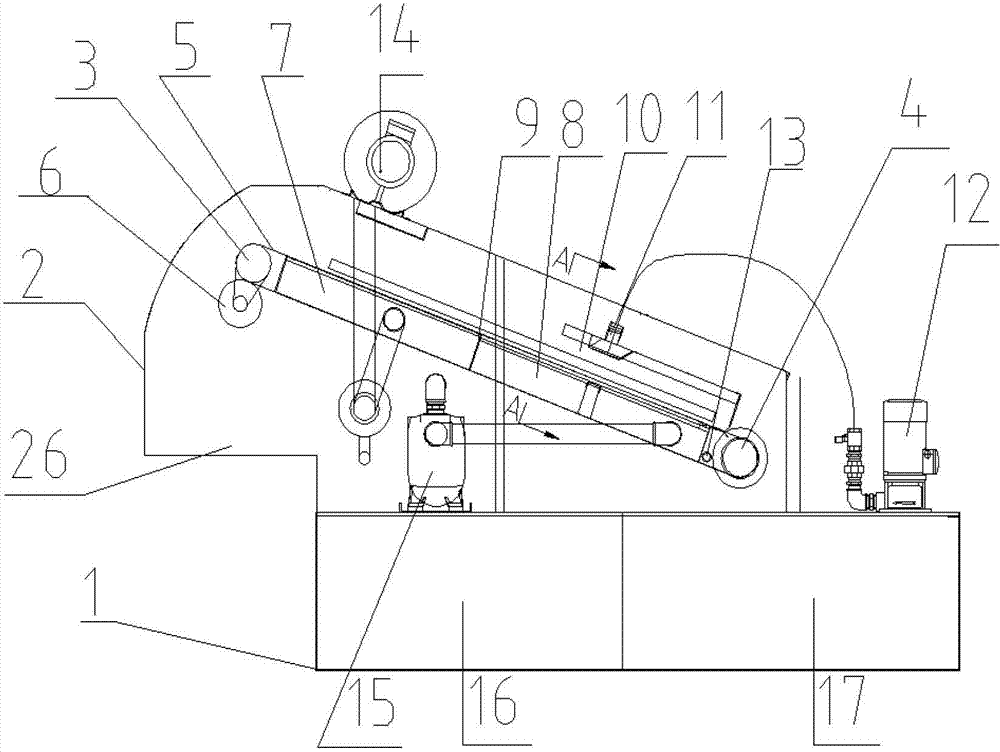

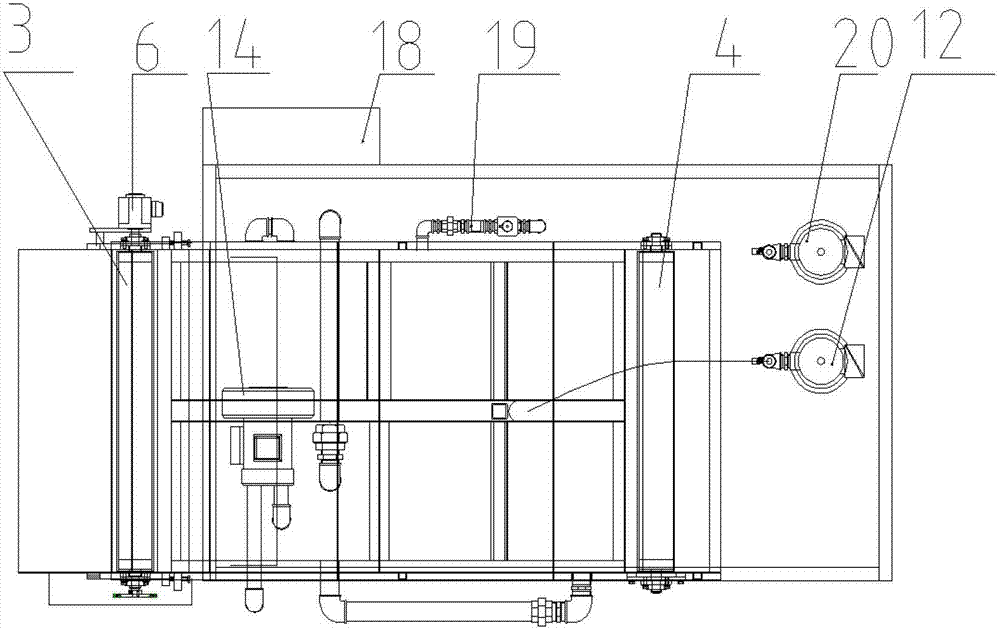

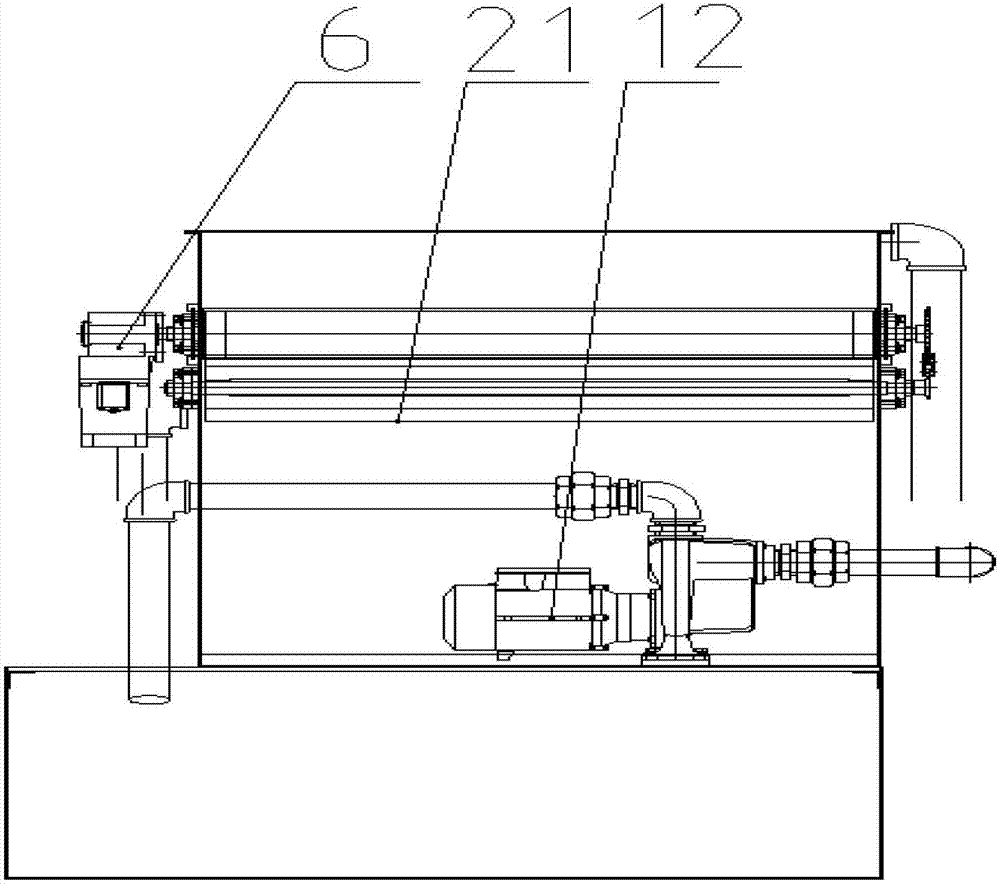

[0029] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

[0030] Such as Figure 1-Figure 3 As shown, the suction circulation belt filter device provided by the invention includes a liquid tank 1 and a housing 2, the housing 2 is fixed on the liquid tank 1, and a power roller 3 is fixed at one end in the housing 2, and the other One end is fixed with a driven roller 4, and the position of the power roller 3 in the housing 2 is higher than that of the driven roller 4, and the housing 2 under the power roller 3 is provided with a slag outlet 26. A cleaning brush 21 is installed under the power roller 3, and the cleaning brush 21 is in contact with the surface of the filter belt 5. The filter belt 5 is wound on the power roller 3 and the driven roller 4, and a control device...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com