Novel high-efficiency haze filtration silver nanowire net and MOFs composite porous fiber film material and preparation method thereof

A high-efficiency filtration and porous fiber technology, applied in separation methods, chemical instruments and methods, membrane technology, etc., can solve the problems of non-compliance with hygiene requirements, poor filtration effect, difficult to remove, etc., to achieve good tensile resistance, avoid falling off, The effect of preventing the growth of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

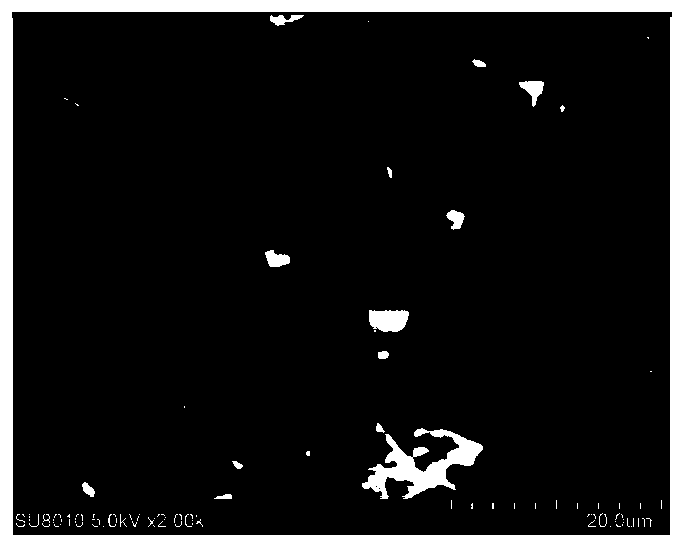

Image

Examples

Embodiment 1

[0041] A method for preparing a novel smog efficient filter silver nanowire network and MOFs composite porous fiber film material, comprising the following steps:

[0042] (1) Preparation of spinning precursor solution: Weigh 1g of PVP powder and add it to 9g of ethanol, stir magnetically for 12h, and let stand for 2h to obtain spinning precursor solution;

[0043] (2) Preparation of spinning solution: Mix 0.05g of silver nanowires with the spinning precursor solution and stir magnetically for 2h to obtain a PVP-ethanol-silver nanowire dispersion; then weigh 0.05g of MOF-5 powder and add 5g In the PVP-ethanol-silver nanowire dispersion, magnetically stirred for 3 hours to prepare a spinning solution, the composition of the spinning solution is PVP-ethanol-MOF-5-silver nanowire dispersion;

[0044] (3) Electrospinning: Add the spinning solution (PVP-ethanol-MOF-5-silver nanowire dispersion) into the spinning equipment, and perform electrospinning to prepare a mixed fiber film; ...

Embodiment 2

[0046] A method for preparing a novel smog efficient filter silver nanowire network and MOFs composite porous fiber film material, comprising the following steps:

[0047] (1) Preparation of spinning precursor solution: Weigh 1g of PVP powder and add it to 9g of ethanol, stir magnetically for 12h, and let stand for 2-5h to obtain spinning precursor solution;

[0048] (2) Preparation of spinning solution: Mix 0.05g silver nanowire with spinning precursor solution, stir magnetically for 2h to obtain PVP-ethanol-silver nanowire dispersion; weigh 0.05g of MOF-5 powder and add 5g of During the mixing of the spinning precursor solution, magnetically stir for 3 hours to prepare a PVP-ethanol-MOF-5 dispersion;

[0049] (3) Electrospinning: adding the spinning solution (PVP-ethanol-silver nanowire dispersion and PVP-ethanol-MOF-5 dispersion) into the spinning equipment, and performing electrospinning to prepare a mixed fiber film; Electrospinning process control conditions: the voltag...

Embodiment 3

[0053] A method for preparing a novel smog efficient filter silver nanowire network and MOFs composite porous fiber film material, comprising the following steps:

[0054] (1) Preparation of spinning precursor solution: Weigh 1g of PVP powder and add it to 9g of ethanol, stir magnetically for 12h, and let stand for 2-5h to obtain spinning precursor solution;

[0055] (2) Preparation of spinning solution: Mix 0.05g of silver nanowire with spinning precursor solution, and magnetically stir for 2h to obtain spinning solution, which is composed of PVP-ethanol-silver nanowire dispersion;

[0056] (3) Electrospinning: the spinning solution (PVP-ethanol-silver nanowire dispersion) is added to the spinning equipment for electrospinning to prepare a mixed fiber film; the control conditions of the electrospinning process: the voltage is set to 15kv, the distance between the injector and the collector is 15cm, the flow rate is set to 1mL / h, the left and right swing distance is 10cm, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com