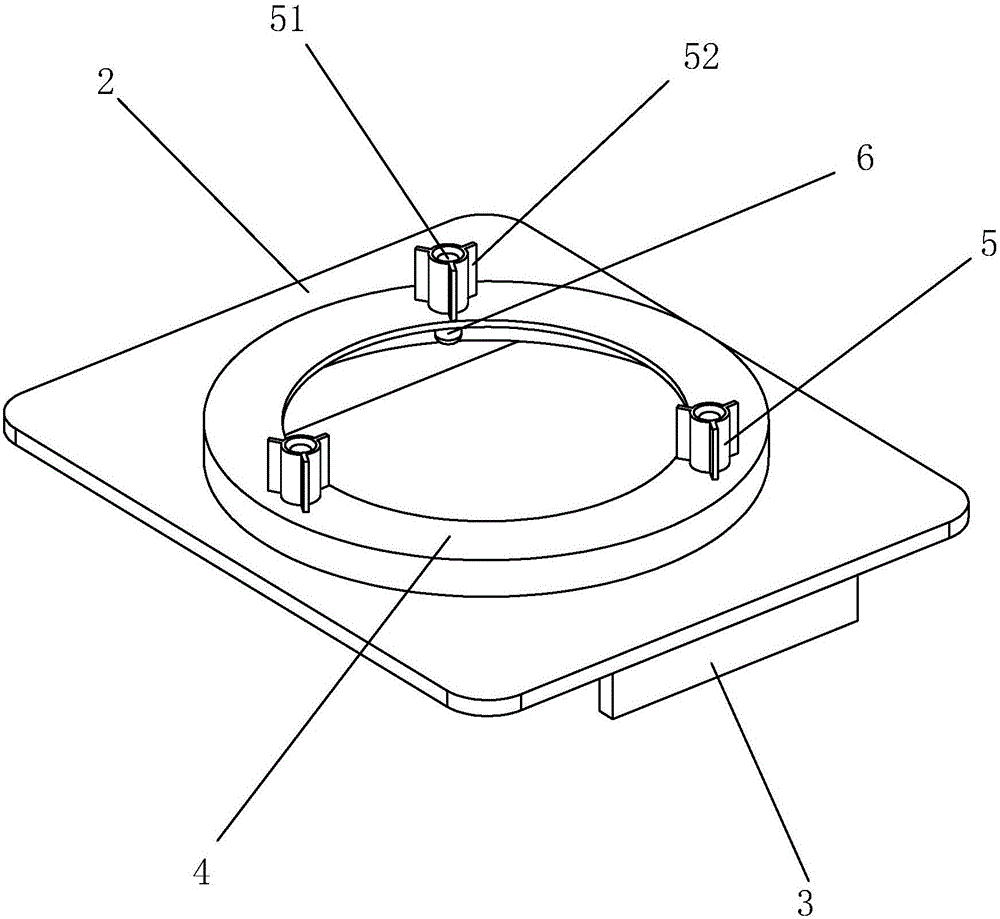

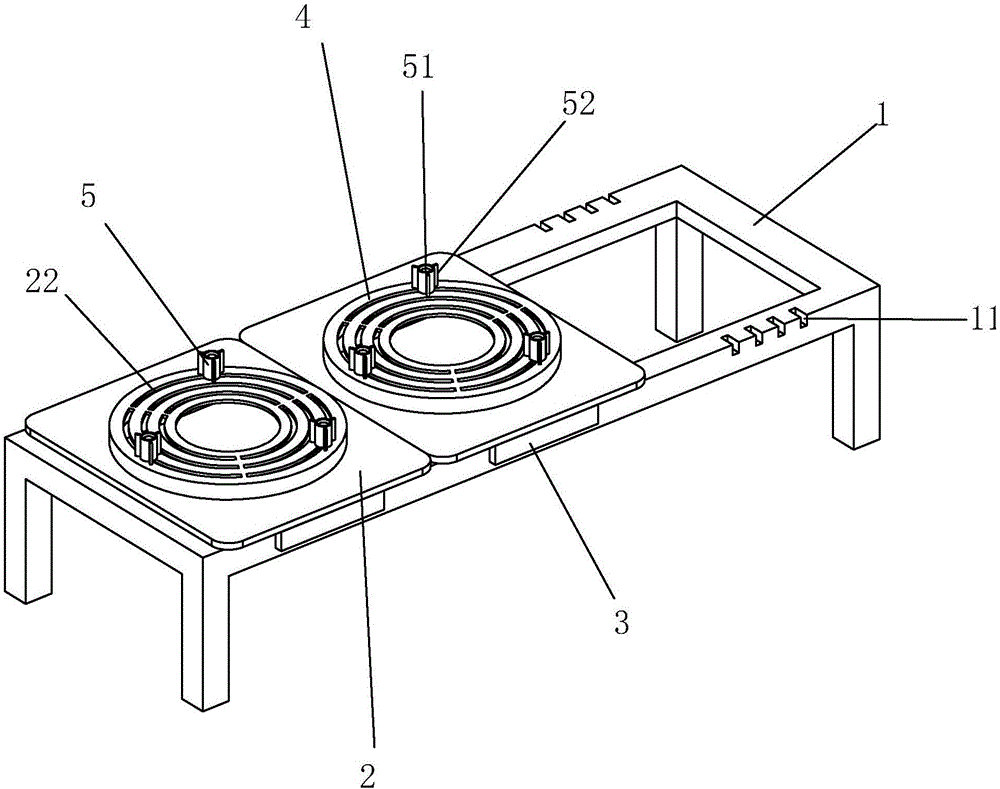

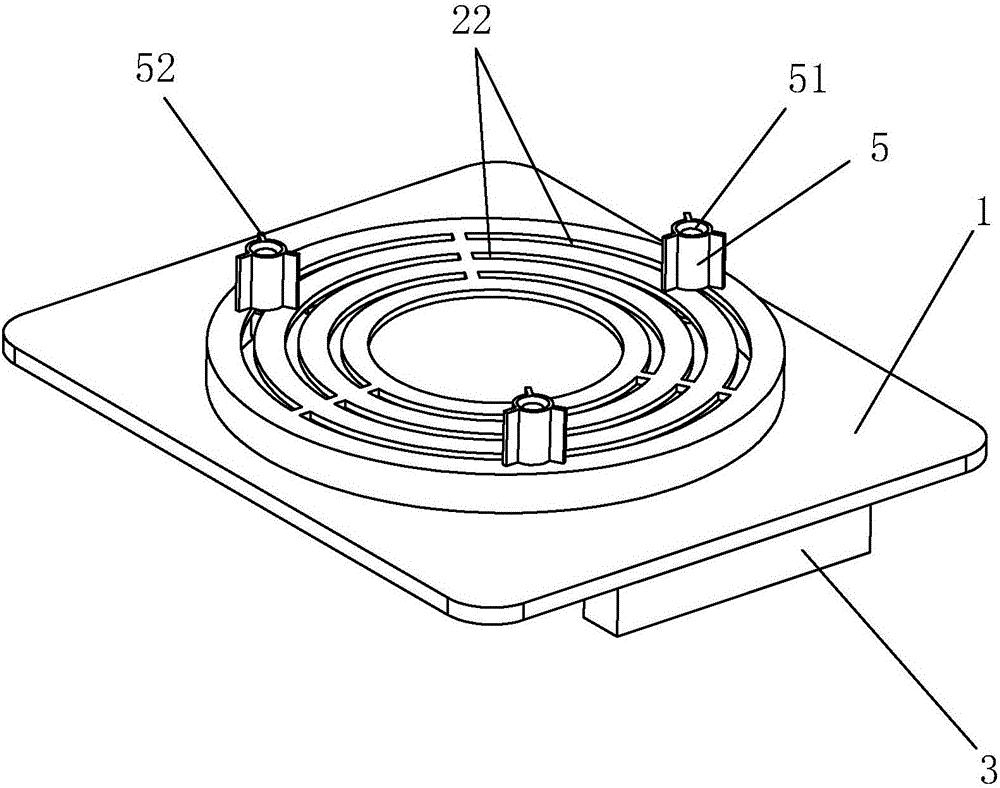

Paint spraying jig

A technology of fixtures and paint spraying racks, applied in the direction of spraying devices, etc., can solve the problems of inconvenient replacement, and achieve the effects of simple structure, avoiding damage, easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0044] The difference from Embodiment 1 is that in this embodiment, the protection layer 8 is a stain-resistant and light-emitting flexible composite material layer. The pollution-resistant and luminescent flexible composite material layer is uniformly coated with the pollution-resistant and luminescent flexible composite material. The pollution-resistant and luminous flexible composite material has very good pollution resistance, and therefore can play a very good protective effect on paint. For the preparation and specific properties of the pollution-resistant luminescent flexible composite material, please refer to the article "Preparation and Performance Research of the Pollution-Resistant Luminescent Flexible Composite Material" by Master Zhou Xiaorong of Xi'an Polytechnic University, which belongs to the prior art and will not be described here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com