Device and process for continuous separation of coal tar components

A separation device and coal tar technology, applied in the field of coal chemical industry, can solve the problems of difficult investment cost, separation of product components and low utilization efficiency, and complexity, and achieve the effects of small footprint, easy expansion of production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

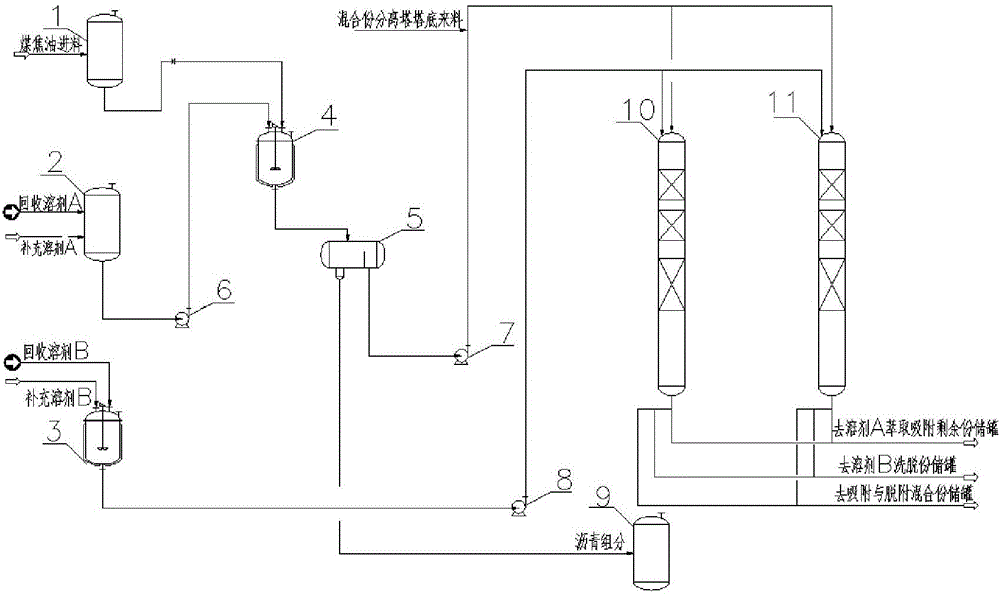

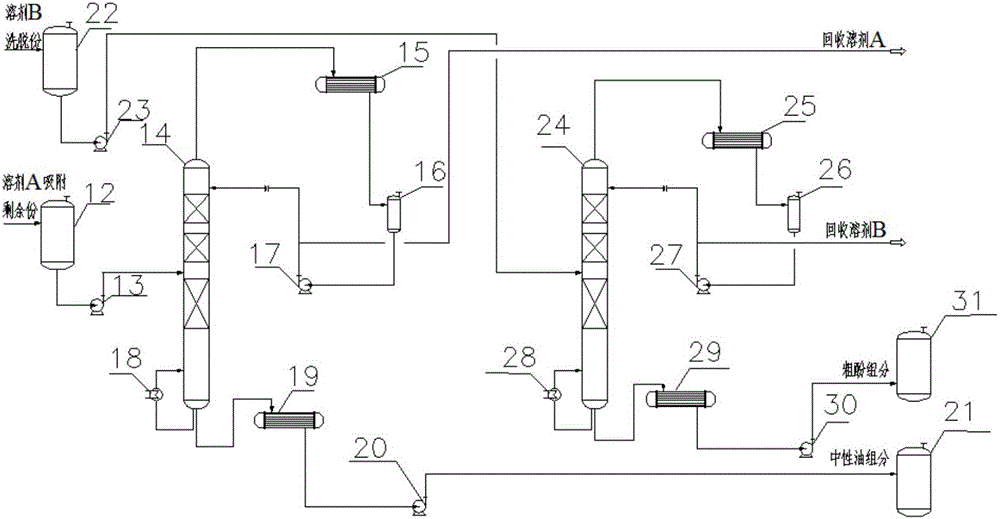

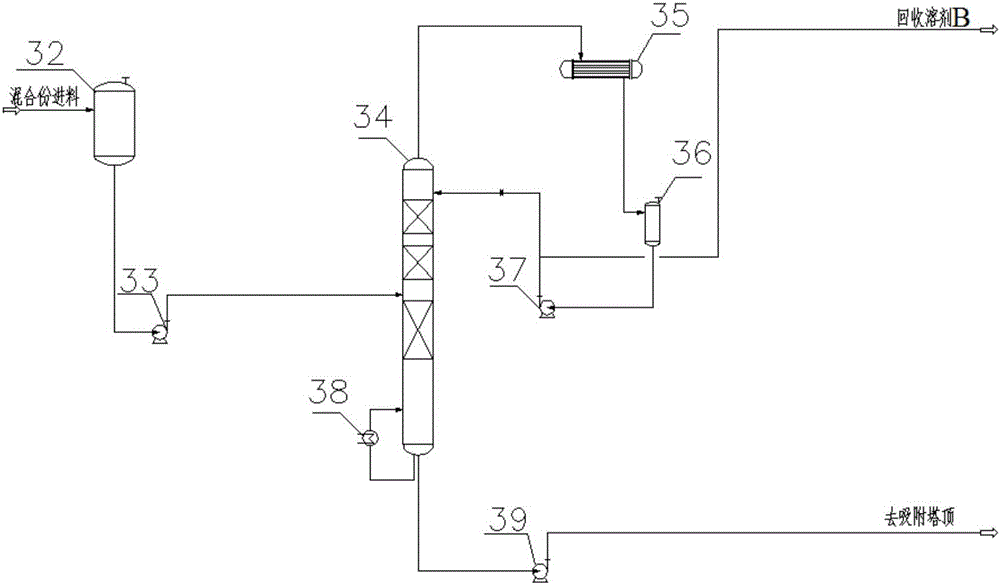

[0059] The present invention will be described in further detail below through embodiments in conjunction with the accompanying drawings.

[0060] All raw materials, intermediate products and storage tanks described in the present invention are equipped with liquid level control; the coal tar extraction reactor is equipped with a heating jacket and stirring device; the solvent A feeding tank is equipped with a heating jacket; The bottom of the above-mentioned adsorption tower is connected with three pipelines respectively.

[0061] see figure 1 , figure 2 and image 3 A coal tar component continuous separation device comprising: coal tar feed storage tank 1, solvent A storage tank 2, solvent B preheating storage tank 3, coal tar extraction reaction kettle 4, asphalt component separation storage tank 5, solvent A feed pump 6, solvent A extract feed pump 7, solvent B feed pump 8, asphalt component storage tank 9, first adsorption tower 10, second adsorption tower 11, solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com