A comprehensive treatment method for laterite nickel ore hydrometallurgy wastewater

A laterite nickel ore and comprehensive treatment technology, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of high treatment costs, environmental pollution, and complex components of magnesium-containing aqueous solutions and other issues, to achieve the effect of low cost, avoiding environmental pollution, and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

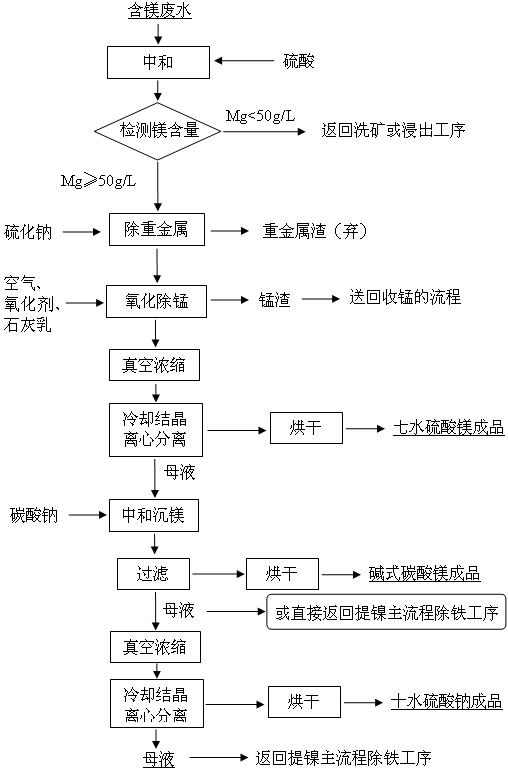

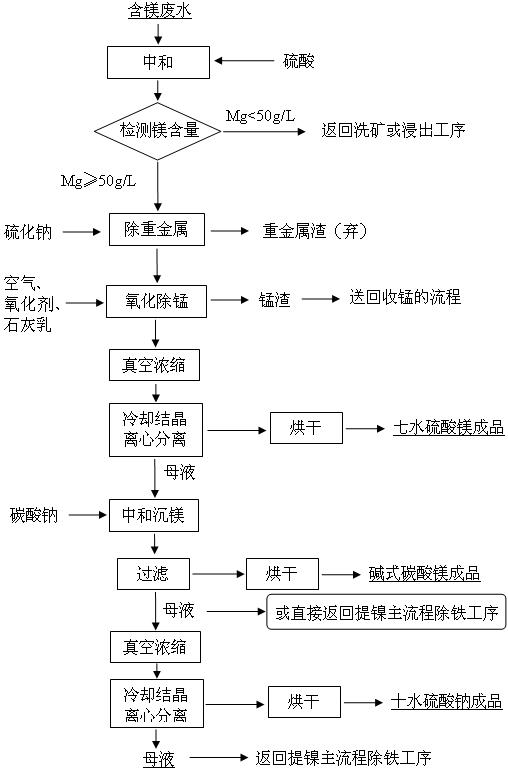

Image

Examples

Embodiment 1

[0028] A kind of magnesium-containing wastewater produced during the hydrometallurgical nickel precipitation and refining process of laterite nickel ore, the specific components are:

[0029] element Mg Ca Na mn heavy metal pH value Contentg / L 17.89 0.36 5.96 0.11 0.01 8.5

[0030] The content of Mg in the wastewater is low, so the wastewater is adjusted to pH = 7 with sulfuric acid, and then returned to the laterite nickel ore washing process as water for ore washing and pulping, and then the nickel and magnesium are leached out through the acid leaching process, and the precipitated nickel is separated to produce Magnesium-containing wastewater. After 2 cycles, the concentration of magnesium in magnesium-containing wastewater increased to 53g / L. Add the waste water to the stirring tank, raise the temperature to 60°C, analyze the heavy metal content in the waste water, add sodium sulfide according to 1.5 times the total molar mass of the ...

Embodiment 2

[0032] The composition of the magnesium-containing wastewater is the same as in Example 1. The wastewater is adjusted to pH = 7 with sulfuric acid, and then directly returned to the acid leaching process as process water to leach nickel and magnesium. The magnesium-containing wastewater produced after the nickel precipitation and separation is returned to the acid leaching process again. After 2 cycles, the concentration of magnesium in magnesium-containing wastewater increased to 50g / L. Add the waste water to the stirring tank, analyze the heavy metal content in the test waste water, add sodium sulfide according to 1.0 times the total molar mass of the heavy metal in the waste water, react at room temperature for 90 minutes, and filter to remove the heavy metal. Adjust the pH value of this aqueous solution to 8.0 with milk of lime, pass air into the aqueous solution to oxidize low-valent manganese, add a small amount of hydrogen peroxide during the process, react at room tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com