Process for preparing magnesium sulphate heptahydrate in treatment of industrial waste sulphuric acid liquid

A technology of magnesium sulfate heptahydrate and waste sulfuric acid, applied in magnesium sulfate and other directions, to achieve the effects of high recovery rate, significant social benefits and less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

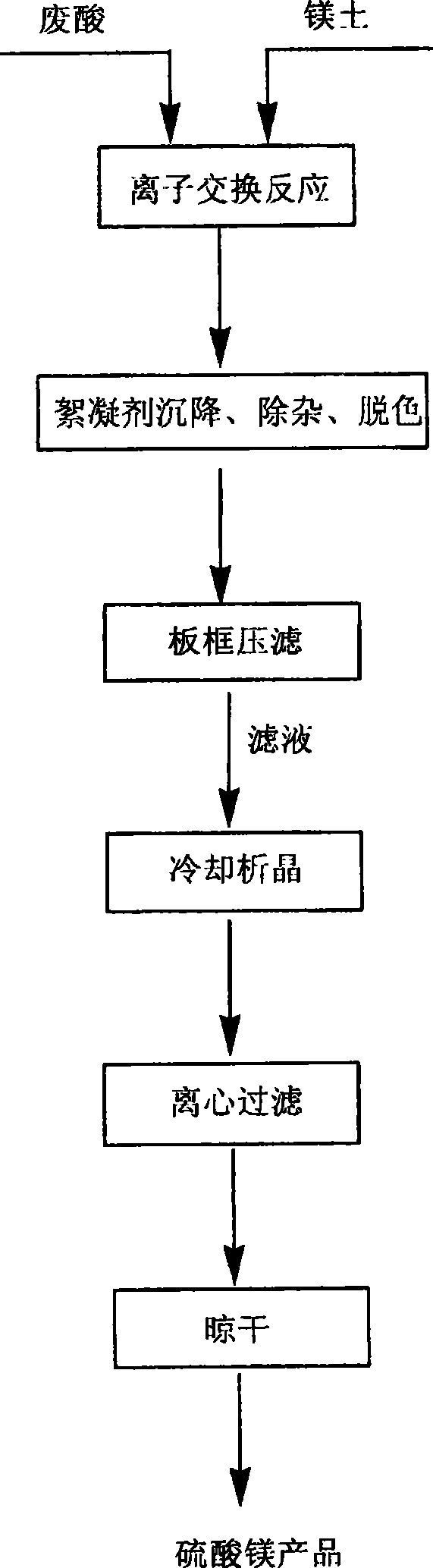

Image

Examples

Embodiment 1

[0016] The following examples describe the inventive content of the invention. This example utilizes the waste acid produced in the process of producing m-hydroxybenzoic acid and 4-hydroxybiphenyl sulfonated alkali fusion as a raw material to produce magnesium sulfate heptahydrate. 1388g was put into a 2000ml round bottom flask with stirring, slowly added 200g of magnesia containing 85% magnesia, stirred for 30min, adjusted the pH of the reaction solution to make it 7, and continued to stir to make it fully react. After the reaction is completed, add 0.1 g of polysilicon aluminum ferric chloride to the reactor for sedimentation, impurity removal and decolorization, stir for 15 minutes, and filter to obtain the filter residue cationic polyacrylamide, and the mud and mechanical impurities removed by sedimentation. The obtained mother liquor was cooled naturally, crystals were precipitated, and 1045.5 g of white crystals of magnesium sulfate heptahydrate were obtained by filtrati...

Embodiment 2

[0018] Add 120L of sulfonated alkali-melted waste sulfuric acid with a concentration of 30% and 59.8kg of magnesia containing 85% magnesia in a 200L reactor, start stirring, let it react for 1 hour, adjust the pH of the reaction solution to make it 7, continue Stir to fully react. After fully functioning, add 12g of cationic polyacrylamide to the reaction solution for sedimentation, impurity removal and decolorization. After stirring for 30 minutes, put the solution mixed with cationic polyacrylamide into the plate and frame filter press with a high-pressure pump to remove the cationic polyacrylamide. Acrylamide and mud and mechanical impurities removed by sedimentation. 10.47 kg of filter residue and 312.6 kg of magnesium sulfate filtrate were separated by plate and frame pressure filtration, and the obtained filtrate was naturally cooled to precipitate crystals. The above mixed solution is placed in a centrifuge and filtered to obtain wet magnesium sulfate heptahydrate crys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com