Plant ash seedling-growing matrix and preparation method thereof

A technology for raising seedlings and plant ash, which is applied in the field of agricultural cultivation, can solve the problems of waste of resources, low density of plant ash, high packaging and transportation costs, and achieves the effect of solving garbage discharge, promoting popularization and application, and having significant environmental and social benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

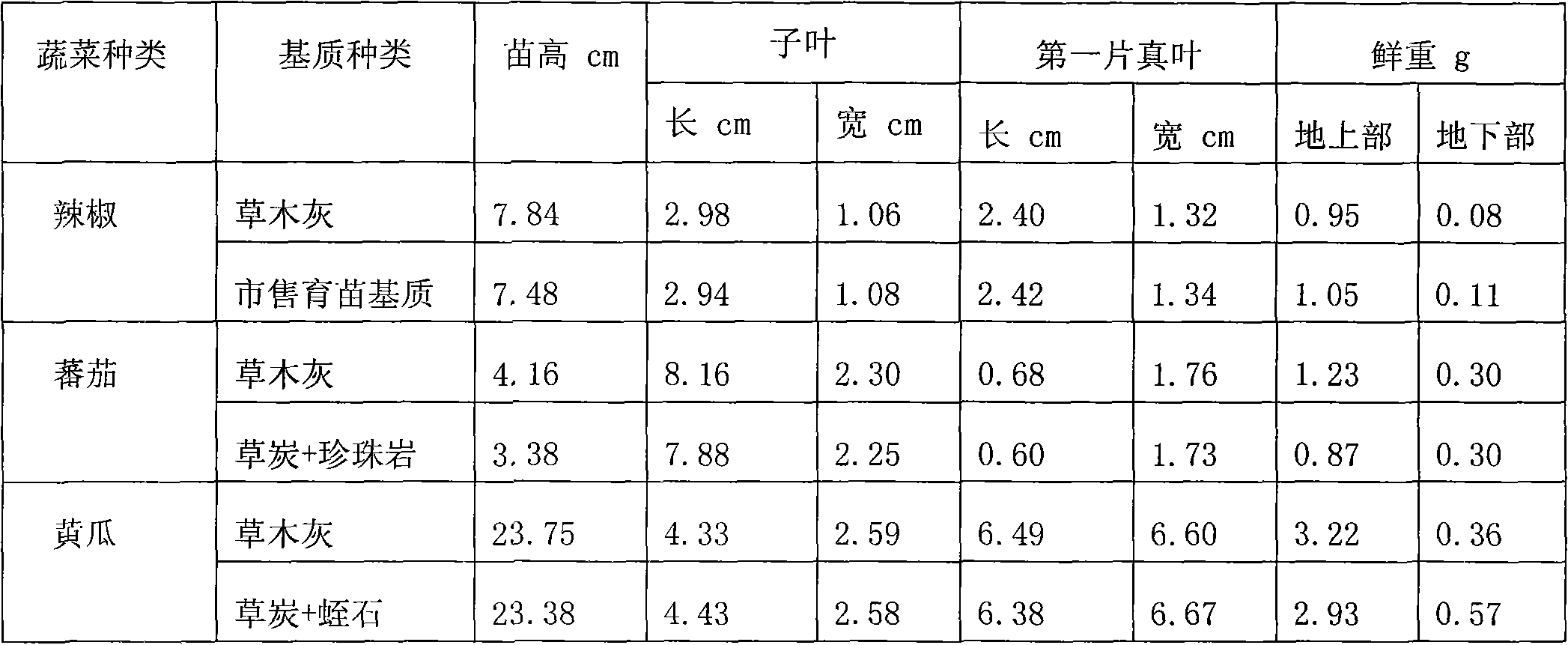

Image

Examples

Embodiment 1

[0022] Prepare the plant ash seedling substrate for seedling cultivation in the plug tray: the depth of the pool is more than 0.6m, and the volume is 3m 3 Add plant ash weighing about 1T in the washing filter tank, rinse with water until the conductivity of the water outlet is less than 2ms / cm, stop washing and filtering, discharge the ash, centrifugal dehydration, take the dehydrated ash 1000kg, the water content is about 40% (wet basis ), the conductivity of its salt content is 1.5ms / cm. Add 10% sulfuric acid (H 2 SO 4 ) and 10% ferrous sulfate (FeSO 4 .7H 2 (2) 150kg of mixed acid-adjusting solution, fully mix well, pile up and place for 4 hours; then add 3% nitric acid solution 100kg, cross 100 mesh sieve attapulgite 150kg, 1.5% polyacrylamide (PAM) solution 100Kg, add while adding Stir, mix well and serve. The formulated matrix has a bulk density of 0.3g / cm 3 About, the total porosity is about 90%, of which the ventilation pores account for about 20% of the total po...

Embodiment 2

[0024] Prepare plant ash seedling raising matrix nutrient block: get the ash residue 1000kg that washes salt and dehydration, add concentration to be 20% sulfuric acid (H 2 SO 4 ) and 20% ferrous sulfate (FeSO 4 .7H 2 80kg of mixed acid-adjusting liquid of (0), fully mix thoroughly, pile up and place 5 hours; Add 20kg of 10% ammonium nitrate solution, 150kg of attapulgite, 5% PVA solution 50Kg of 100 mesh sieves, stir while adding, fully mix well . Press the block with a mold, the finished product has a diameter of 3.5cm, a height of 4cm, and a semicircular seeding hole with a depth of 0.5cm in the center of the upper end. The bulk density of nutrition block is about 0.45g / cm 3 , The total porosity is about 80%. When water is supplied from the bottom of the nutrition block, the time for the whole block to absorb enough water is ≤30min. The nutrient block can be directly used for raising seedlings, and can also be used after being dried. The nutrient block is resistant to...

Embodiment 3

[0027] The making of the plant ash seedling-raising matrix that is used for rice machine-transplanted seedlings: get 1000kg of ash slag after washing salt and dehydration, add ferrous sulfate (FeSO 4 .7H 2 (2) 75kg, ammonium sulfate 4kg, ammonium dihydrogen phosphate 0.5kg, fully mix well, pile up and place more than 3 days (because what added is crystal ferrous sulfate (FeSO 4 .7H 2 (2), it needs to be piled up for a long time to allow it to fully react); add yellow clay 300kg, 0.2% PAM solution 300Kg of 40 mesh sieves, stir while adding, fully mix well, can be used for rice machine transplanting and seedling raising. The formulated matrix has a bulk density of 0.3g / cm 3 The total porosity is about 85%, of which the ventilation pores account for about 15% of the total pores, pH7.5, the available nitrogen content reaches 260mg / L, and the available phosphorus content reaches 70mg / L. 1.5kg of the finished product is installed in each standard tray as subsoil, and the upper pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com