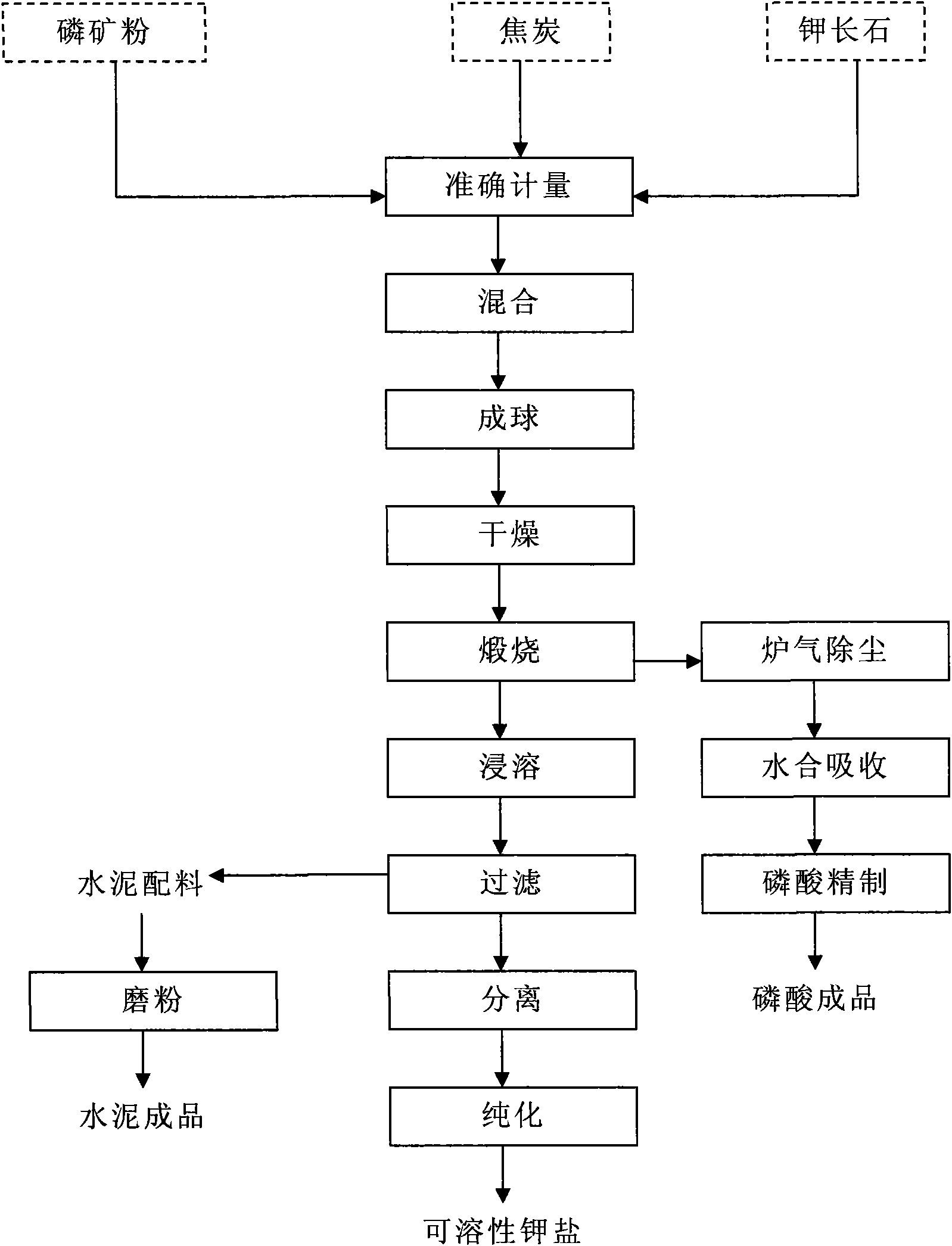

Method for producing phosphoric acid and soluble potassium salt by phosphorus ore and potash feldspar

A technology of potassium feldspar and phosphate rock, which is applied in the field of phosphoric acid and soluble potassium salt production, can solve the problems of complex process flow, high production cost, and high energy consumption, and reduce external heat supply, reduce heat energy consumption, and promote The effect of decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Phosphate rock (containing P 2 o 5 30%, CaO45%), potassium feldspar (containing K 2 O14%, SiO 2 60%) and coke are crushed respectively, the ratio of phosphate ore to coke is equal to 1:0.55 (by weight ratio on a dry basis), and the calcium-silicon ratio between phosphate ore and potassium feldspar is 2.3 (by a molar ratio on a dry basis). For the total amount, weigh 5.26kg, 2.90kg and 1.84kg of phosphate rock, coke and potassium feldspar respectively. Grind in a Ф500×600 ball mill for 1 hour to meet the requirement of 5% of the 180-mesh sieve. Add water to the powder to form a ball and dry it. Take 5kg of the dry sample and put it into a kiln with a diameter of Ф200×1000, and calcinate it for 20 minutes at a temperature of 1200°C. 2 o 5After the kiln gas is dedusted and purified by the dust removal and purification equipment, it enters the hydration tower for hydration and absorption to obtain phosphoric acid, and the conversion rate of phosphorus is 75%. 20:1 soa...

Embodiment 2

[0031] Phosphate rock (containing P 2 o 5 20%, CaO30%), potassium feldspar (containing K 2 O18%, SiO 2 62%) and coke are broken separately, the ratio of phosphate ore to coke is equal to 1:0.35 (by dry basis weight ratio), and the calcium-silicon ratio of phosphate ore and potassium feldspar is 1.8 (by dry basis molar ratio), with In total of 10kg, weigh 6.10kg, 2.14kg and 1.76kg of phosphate rock, coke and potassium feldspar respectively. Grind in a Ф500×600 ball mill for 1 hour to meet the requirement of 5% of the 180-mesh sieve. Add water to the powder to form a ball and dry it. Take 5kg of the dry sample and put it into a kiln with a diameter of Ф200×1000, and calcinate it for 30 minutes at a temperature of 1100°C. 2 o 5 After the kiln gas is dedusted and purified by the dust removal and purification equipment, it enters the hydration tower for hydration and absorption to obtain phosphoric acid, and the conversion rate of phosphorus is 74.52%. Soak in 15:1 for 12 hou...

Embodiment 3

[0033] Phosphate rock (containing P 2 o 5 15%, CaO22.5%), potassium feldspar (containing K 2 O10%, SiO 2 68%) and coke are respectively crushed, the ratio of phosphate rock to coke is equal to 1:0.45 (by weight ratio on a dry basis), and the calcium-silicon ratio of phosphate rock and potassium feldspar is 2.0 (by molar ratio on a dry basis). In the total amount of 10kg, 6.15kg, 2.76kg and 1.09kg of phosphate rock, coke and potassium feldspar were weighed respectively. Grind in a Ф500×600 ball mill for 1 hour to meet the requirement of 5% of the 180-mesh sieve. Add water to the powder to form a ball and dry it. Take 5kg of the dry sample and put it into a kiln with a diameter of Ф200×1000, and calcinate it for 10 minutes at a temperature of 1400°C. 2 o 5 After the kiln gas is dedusted and purified by the dust removal and purification equipment, it enters the hydration tower for hydration and absorption to obtain phosphoric acid, and the conversion rate of phosphorus is 87...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com