Preparation of 2,2-disulfo-dibenzopyrene by oxygen process based on 2-mercaptan benzothiazole ammonia salt

A technology of dithiodibenzothiazole and dithiodibenzothiazole, which is applied in the field of preparation 2, can solve problems such as high risk, high toxicity, and difficult control of the process, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

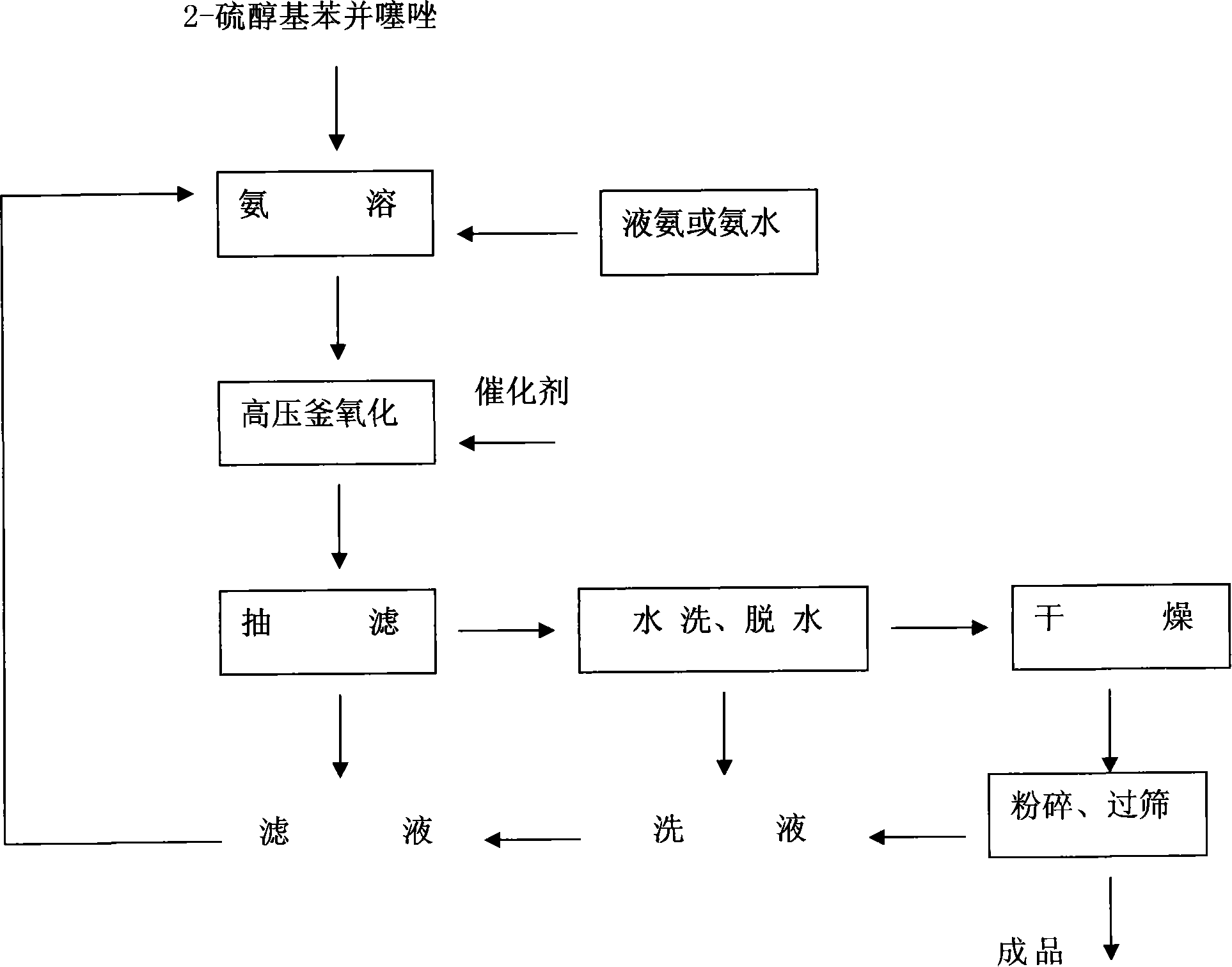

Method used

Image

Examples

Embodiment 1

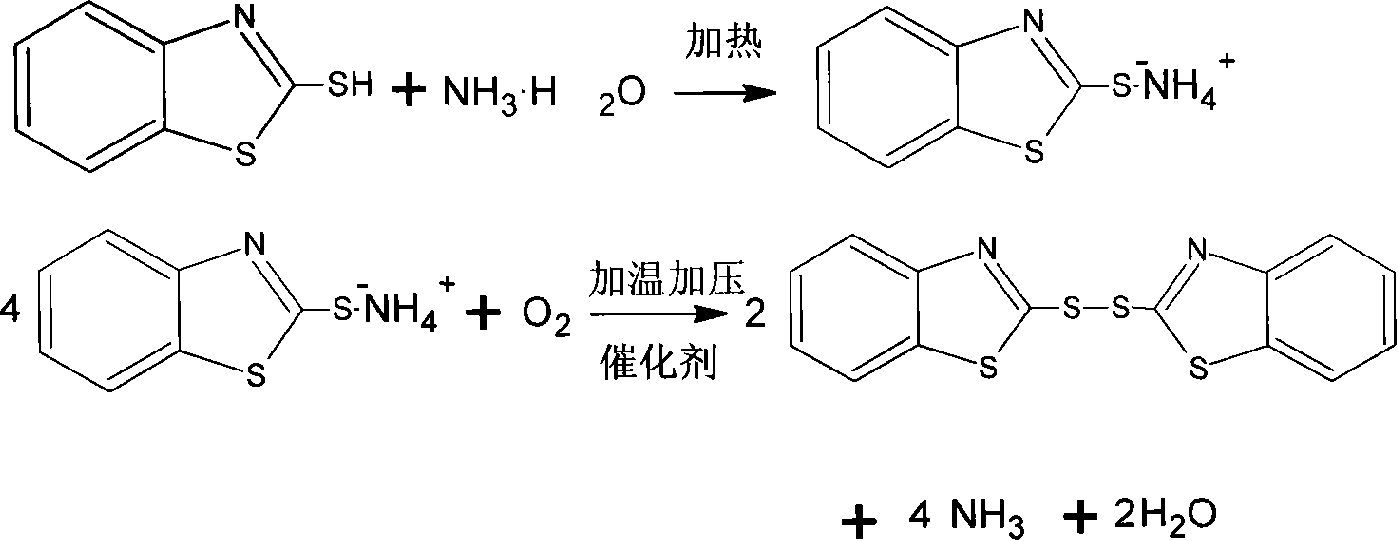

[0013] 1. Weigh 50 grams of refined 2-mercaptobenzothiazole and add it to the container, then add 200 grams of 25% ammonia water and 720 grams of water, heat the container to 70 ° C, and stir during the heating process to make 2- Mercaptobenzothiazole is fully dissolved in the solution;

[0014] 2. Put the obtained ammonium salt solution of 2-mercaptobenzothiazole at room temperature, filter it and add it to the reactor, add 0.45 g of copper sulfate catalyst, and feed oxygen to make the raw material undergo oxidation-reduction reaction, and keep the temperature of the reactor at 50°C ; Pressure 1.0mMPa, reaction time 120min;

[0015] 3. After the reaction time is over, open the reaction kettle, and suction filter the solution; obtain a filter cake; wash the filter cake with water, dry, and pulverize to obtain 43.45 grams of the target product 2,2'-dithiodibenzothiazole.

[0016] 5. Tested by the GB11408-89 method, the purity is >90%, and the yield is 86.9%.

Embodiment 2

[0018] 1. Weigh 50 grams of crude 2-mercaptobenzothiazole and add it to a four-necked flask, add 45 grams of liquid ammonia and 470 grams of water, heat the container to 40°C, and stir during the heating process to make the 2-mercaptan The base benzothiazole is fully dissolved in the solution;

[0019] 2. Put the ammonium salt solution of 2-mercaptobenzothiazole at room temperature, filter it and add it to the reaction kettle, add 0.45 g of catalyst copper acetate catalyst; when the ammonium salt solution is 70-75°C, air is introduced to oxidize the raw material For reaction, keep the container pressure at 0.6MPa, and the reaction time is 100min;

[0020] 3. After the reaction is over, open the reaction kettle and filter the solution with suction; obtain a filter cake;

[0021] 4. The filter cake was washed with water, dried and pulverized to obtain 35.75 g of 2,2'-dithiodibenzothiazole.

[0022] 5. Tested by GB11408-89 method, the purity is >90%, and the yield is 71.5.5%. ...

Embodiment 3

[0024] 1. Weigh 50 grams of crude 2-mercaptobenzothiazole and add it to the container, add 450 grams of 40% ammonia and 500 grams of water, heat the container to 55 ° C, and stir during the heating process to make the 2-thiol The base benzothiazole is fully dissolved in the solution;

[0025] 2. After the ammonium salt solution of 2-mercaptobenzothiazole is left to stand at room temperature, it is filtered and added to the reactor, and 1.95 grams of catalyst manganese acetate is added in a ratio of 0.15% by weight, and air is introduced to make the raw material undergo redox reaction. Keep the container pressure at 0.8MPa, the reaction temperature of the reactor is 80°C; the reaction time is 60min,

[0026] 3. After the reaction, the reaction kettle was opened, and the solution was suction-filtered; the filter cake was obtained, which was washed, dried, and pulverized to obtain 29.85 grams of the target product 2,2'-dithiodibenzothiazole.

[0027] 4. Tested by the GB11408-89 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com