Injectable bioactive bone cement as well as preparation method and application thereof

A bioactive, bone cement technology, applied in medical science, prostheses, etc., can solve the problems that limit the wide application of PMMA bone cement, do not have bioactivity and degradation performance, burn surrounding tissues, etc., to improve biocompatibility, Promoting mineralization, good compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

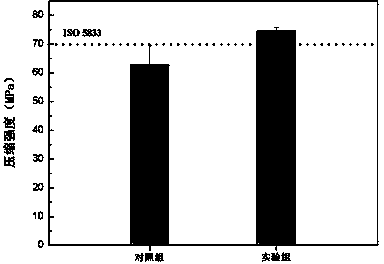

[0041] In the first step, 5 g of P(MMA- co -MPS) powder, add a mixed solution of 90% ethanol / water and adjust the pH value of the solution to 3.5-4.0, after one hour of reaction, add 200ml of 8g hydroxyapatite suspension that has been dispersed by ultrasonic in advance and adjust the pH of the whole system pH value to 10.0, reacted overnight, the product was filtered, ultrasonically cleaned three times with tetrahydrofuran, and vacuum-dried to obtain P(MMA- co -MPS)-HA powder.

[0042] In the second step, 0.4 g of the surface-modified hydroxyapatite powder obtained in the first step is mixed with 0.6 g of PMMA powder with a molecular weight of 700,000 and sterilized to obtain the powder part of the bone cement. The liquid part of the bone cement consisted of 2ml of MMA solution dissolved with 0.03g of BPO and 14ul of DMT. The bone cement powder component and the liquid component are mixed, stirred and evenly mixed, and injected into a mold through a syringe. The hyd...

Embodiment example 3

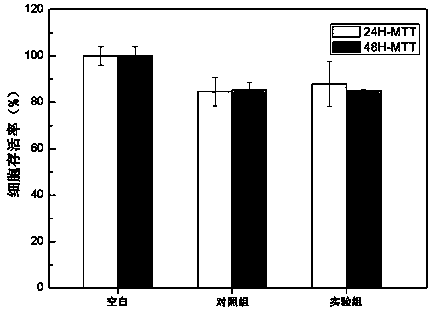

[0048]Hemolysis rate test sample size: a cylinder with a height of 10 mm and a width of 10 mm, and the bone cement sample used is the bone cement described in Example 1.

[0049] The first step, preparation of extraction solution: After each bone cement sample was soaked in alcohol for 24 hours and sterilized, it was soaked in phosphate buffer solution (PBS) at a ratio of 0.5ml / g at 37°C for 48 hours to obtain an extraction solution.

[0050] In the second step, the HA / PMMA bone cement material PBS extraction solution, PBS (negative control) and double distilled water (positive control) were mixed with 5 parts for each group, 2ml for each tube.

[0051] In the third step, add 2mL of 2% fresh healthy human blood suspension to each tube, incubate at 37°C for 4 hours, centrifuge at 1000r / min for 5min, take 1mL of supernatant, and measure the absorbance of each sample at 540nm under a microplate reader.

[0052] The fourth step, calculation of hemolysis rate: hemol...

Embodiment example 4

[0054] Mineralization test sample size: a cylinder with a height of 5 mm and a width of 6 mm, and the bone cement sample used is the bone cement described in Example 1.

[0055] After two groups of samples were soaked in human simulated body fluid (SBF) for 3 days, the surface of the bone cement samples was washed with PBS, and after drying, the mineralization of the bone cement surface was photographed with a scanning electron microscope (SEM). Experimental results such as Figure 4 Compared with before soaking, hydroxyapatite was newly formed on the surface of the bone cement in the two groups, indicating that this bone cement is conducive to mineralization; moreover, the hydroxyapatite formed in the experimental group on the third day was significantly more than that in the control group, It shows that the mineralization performance of the experimental group is better than that of the control group.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com