Large-particle vertical ring pulsation high-gradient magnetic separator

A high-gradient magnetic separator and large particle technology, applied in the direction of high-gradient magnetic separator, etc., can solve the problems of magnetic medium blockage of magnetic separator, poor material flow, and failure to use normally, and achieve high enrichment ratio and production Low cost, overcoming serious erosion and wear effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

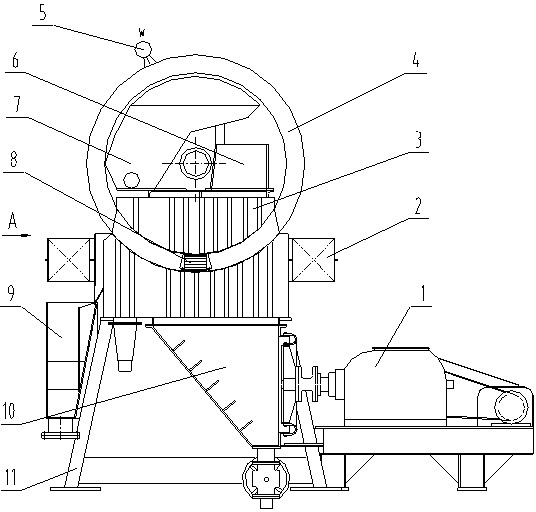

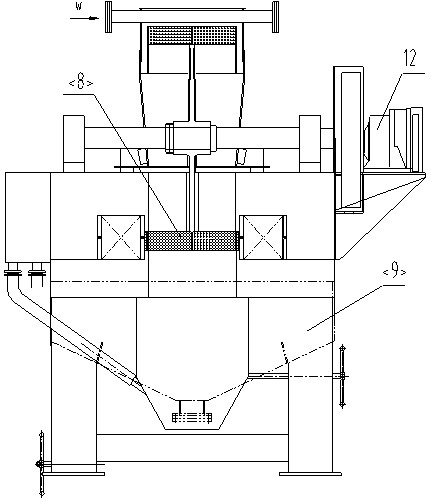

[0024] The large particle vertical ring pulsating high gradient magnetic separator of the present invention is improved on the basis of the existing vertical ring pulsating high gradient magnetic separator, such as Figure 1a , 1b As shown, its composition mainly includes a pulsation mechanism 1, an excitation coil 2, a yoke 3, a swivel 4, a concentrate washing device 5, a feeding hopper 6, a concentrate hopper 7, a magnetic medium pile 8, a concentrate collection tank 9, a tailing Mine bucket 10, frame 11, driving mechanism 12.

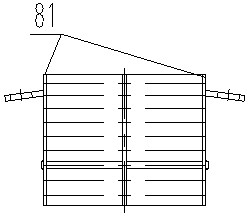

[0025] Such as Figure 2a , 2b As shown, the magnetic medium stack 8 is composed of two thin stainless steel plates 81 arranged at intervals and several dielectric rods 82 spaced therein. In order to meet the requirements of the sorting channel for large particle materials, it not only ensures the high gradient of the magnetic field of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com