Horizontal novel centrifugal concentrator

A centrifugal concentrator, a new type of technology, applied in centrifuges, solid separation, wet separation, etc., can solve the problems of single suitable ore separation, unstable operation, high failure rate, etc., achieve low equipment failure rate and improve separation efficiency , adjustable flow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

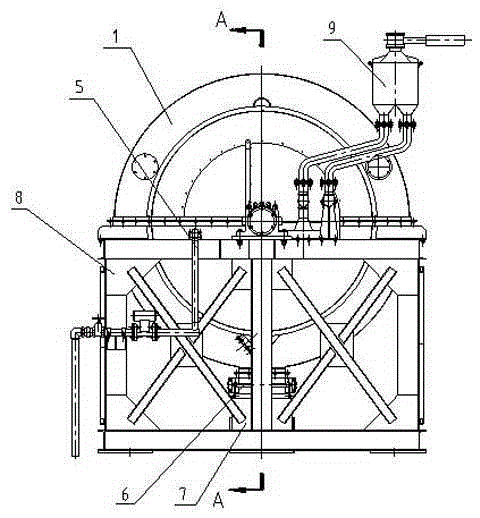

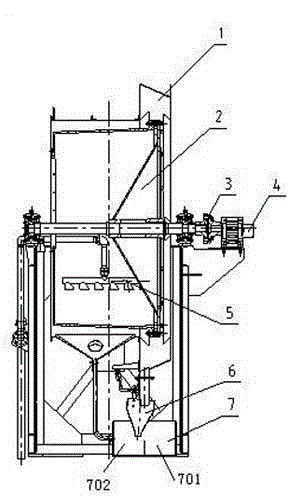

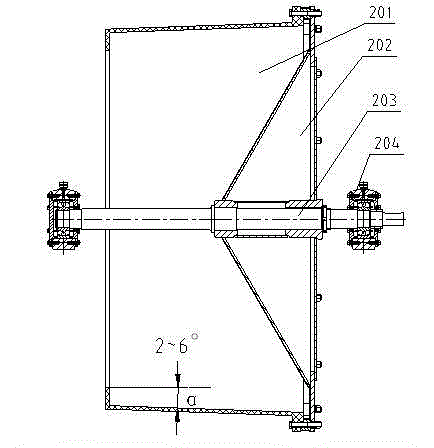

[0023] Such as figure 1 , figure 2 As shown, the present invention includes an outer cover 1, a rotating drum 2, a shaft coupling 3, a frequency conversion deceleration motor 4, a flushing system 5, an ore separator system 6, an ore bucket 7, a frame 8, an ore feeding system 9, and the like. The rotating drum 2 is arranged in the outer cover 1 , and the variable frequency reduction motor 4 is connected with the rotating shaft of the rotating drum through a shaft coupling 3 . Drum 2 as image 3 Shown includes a rotating shaft 203 with both ends mounted on bearing housings 204, a trumpet-shaped turntable 202 set on the rotating shaft with an outward opening, and a frustum-shaped rotating cylinder 201 set outside the turntable. The large end surface of the rotating cylinder and the outer edge of the turntable The rotating drum is fixed on the rotating shaft 203 through the rotating disk 201 through bolt connection, and the opening inclination angle α of the inner wall surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com