Multifunctional electromagnetic centrifugal continuous concentrating machine

A concentrator and centrifugal technology, applied in the field of multi-purpose electromagnetic centrifugal continuous concentrator, can solve the problems of high mineral impurity content, complex process, increased workload, etc., and achieve high beneficiation efficiency, good beneficiation effect, and large processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

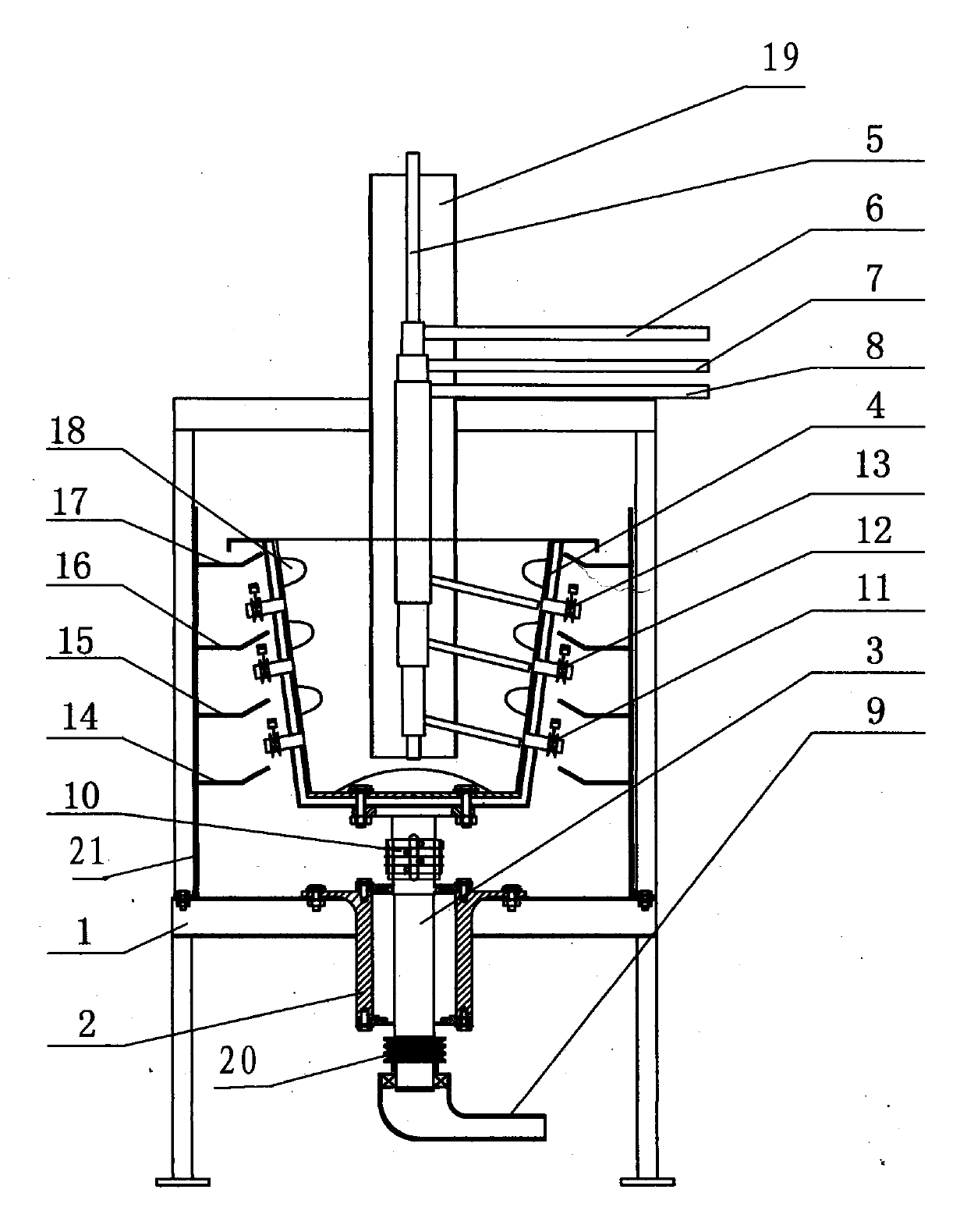

[0016] Referring to the accompanying drawings, the multi-purpose electromagnetic centrifugal continuous concentrator of the present invention includes a main frame 1, an ore collection tube 21 installed on the top of the main frame 1, a sorting cone tube 4 installed in the middle of the ore collection tube 21, and mounted on the main frame 1. Bearing housing 2 with bearing at the lower part, hollow main shaft 3 connected with bearing housing 2, transmission wheel 20 and recoil water pipe 9 installed at the lower part of hollow main shaft 3, ore feeding pipe 5, among which sorting cone 4 is double Layer cavity wall structure, the inner diameter of the upper end is 700mm, the inner diameter of the lower end is 650mm, and the height is 650mm. The lower end of the sorting cone 4 is connected with the upper end of the hollow main shaft 3; a collector ring is installed on the upper part of the hollow main shaft 3 10. The main frame 1 is also equipped with a high-density ore-absorbing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com