Separation method for tennantite and galena

A technology for the separation of arsenite and tetrahedrite, which is applied in the field of copper-lead mixed concentrate separation and beneficiation, can solve problems such as unsatisfactory separation indicators, and achieve the effects of high efficiency and environmental protection of chemicals, good beneficiation effect, and reasonable process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

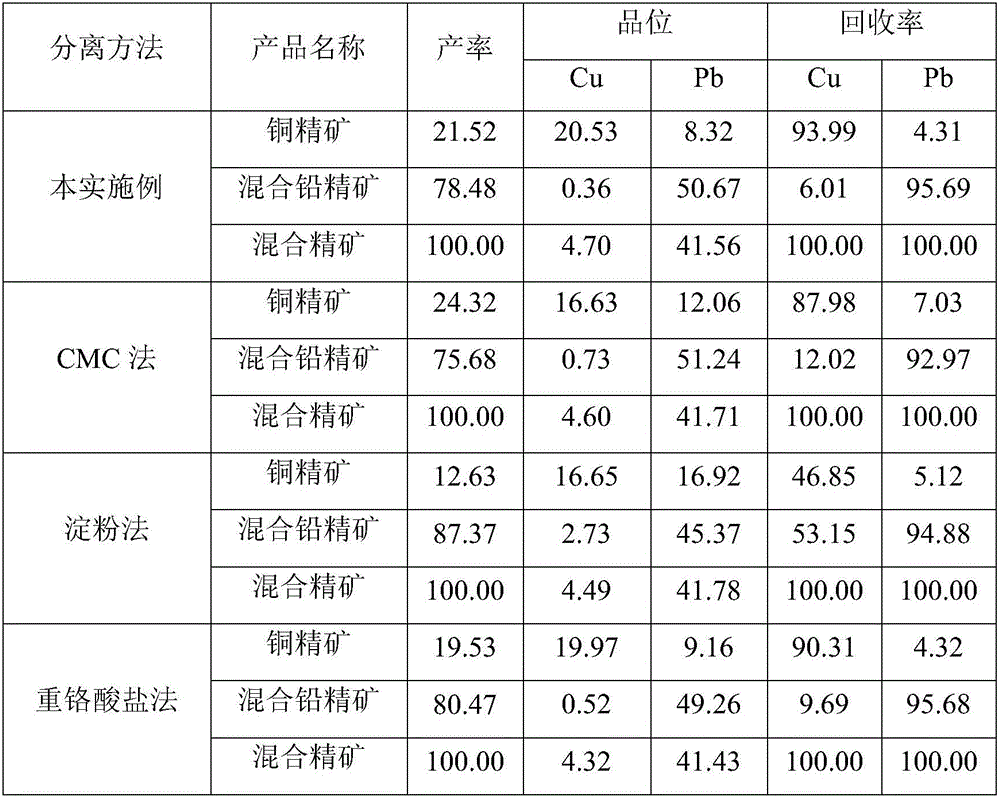

Examples

Embodiment Construction

[0015] The acidic LR inhibitor used in this embodiment is obtained by stirring and mixing sulfuric acid and LS at a mass ratio of 1: (3 to 5) at room temperature; LS is obtained by mixing sodium phosphate solution and carboxymethyl cellulose at a mass ratio of 1 : (1~6) obtained by stirring and mixing at 45~65°C; methyl cellulose is a light yellow fibrous powder prepared from reeds grown in the Dongting Lake area of Hunan Province through the water-enchanting process, and its molecular formula is: C 6 h 7 o 2 (OH) 2.5 (OCH 2 COONa) 1 / 2 ] 70.

[0016] This embodiment provides a method for separating arsenite concentrate and lead concentrate from copper-lead mixed concentrate (mixed ore sample of arsenite and galena), which specifically includes the following steps:

[0017] (1) Aeration and regrinding: import the copper-lead mixed concentrate (the mixed ore sample of arsenite and galena) into the ball mill, fill in the air with a pressure of 1-3MPa, and grind the ore to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com