Low-grade iron mineral flotation collecting agent

A technology of iron minerals and collectors, which is applied in flotation, solid separation, etc., and can solve the problems of complex preparation and various types of agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

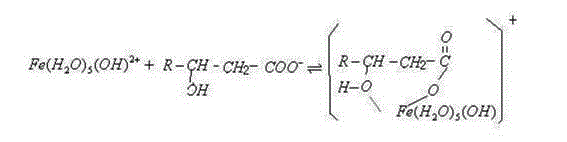

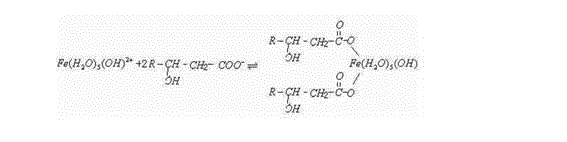

Method used

Image

Examples

Embodiment 1

[0047] α-hydroxyl-carbon chain less than twelve α-hydroxyl-fatty acid 2% Alpha hydroxy-dodecanoic acid 11% Alpha-Hydroxy-Tridec Fatty Acid 1% The sum of the weight percentages of the above three components 14%

[0048] Beta Hydroxyl-December Fatty Acids 1% beta hydroxy-dodecanoic acid 3% beta hydroxy-tridecanoic acid 1% The sum of the weight percentages of the above three components 5%

[0049] Alpha hydroxy-heptadecane fatty acid 3% Alpha hydroxy-octearic fatty acid 10% More than 18 carbon chain α-hydroxy-fatty acids 2% The sum of the weight percentages of the above three components 15%

[0050] beta hydroxy-heptadecane fatty acid 2% β-Hydroxy-octearic fatty acid 3% More than 18 carbon chains β carbon chain hydroxy-fatty acid 1% The sum of the weight percentages of the above three components 6%

[0051] Alpha hydroxy-myristate fatty...

Embodiment 2

[0055] α-hydroxyl-carbon chain less than twelve α-hydroxyl-fatty acid 0% Alpha hydroxy-dodecanoic acid 4% Alpha-Hydroxy-Tridec Fatty Acid 10% The sum of the weight percentages of the above three components 14%

[0056] Beta Hydroxyl-December Fatty Acids 0.3% beta hydroxy-dodecanoic acid 2.7% beta hydroxy-tridecanoic acid 3% The sum of the weight percentages of the above three components 6%

[0057] Alpha hydroxy-heptadecane fatty acid 5% Alpha hydroxy-octearic fatty acid 8% More than 18 carbon chain α-hydroxy-fatty acids 1% The sum of the weight percentages of the above three components 14%

[0058] beta hydroxy-heptadecane fatty acid 0% β-Hydroxy-octearic fatty acid 4% More than 18 carbon chains β carbon chain hydroxy-fatty acid 1% The sum of the weight percentages of the above three components 5%

[0059] Alpha hydroxy-myristate fatty...

Embodiment 3

[0063] α-hydroxyl-carbon chain less than twelve α-hydroxyl-fatty acid 0.5% Alpha hydroxy-dodecanoic acid 5.5% Alpha-Hydroxy-Tridec Fatty Acid 9% The sum of the weight percentages of the above three components 15%

[0064] Beta Hydroxyl-December Fatty Acids 0% beta hydroxy-dodecanoic acid 3% beta hydroxy-tridecanoic acid 2.5% The sum of the weight percentages of the above three components 5.5%

[0065] Alpha hydroxy-heptadecane fatty acid 7% Alpha hydroxy-octearic fatty acid 8% More than 18 carbon chain α-hydroxy-fatty acids 0% The sum of the weight percentages of the above three components 15%

[0066] beta hydroxy-heptadecane fatty acid 1% β-Hydroxy-octearic fatty acid 3% More than 18 carbon chains β carbon chain hydroxy-fatty acid 0.5% The sum of the weight percentages of the above three components 4.5%

[0067] Alpha hydroxy-myri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com