Belt conveyor type magnetic concentrator

The technology of belt conveyor and mineral processing machine is applied in the field of mineral processing machinery, which can solve the problems of increased production cost, poor mineral processing effect, high manufacturing cost, etc., and achieves the effects of low manufacturing cost and use cost, simple structure and good mineral processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

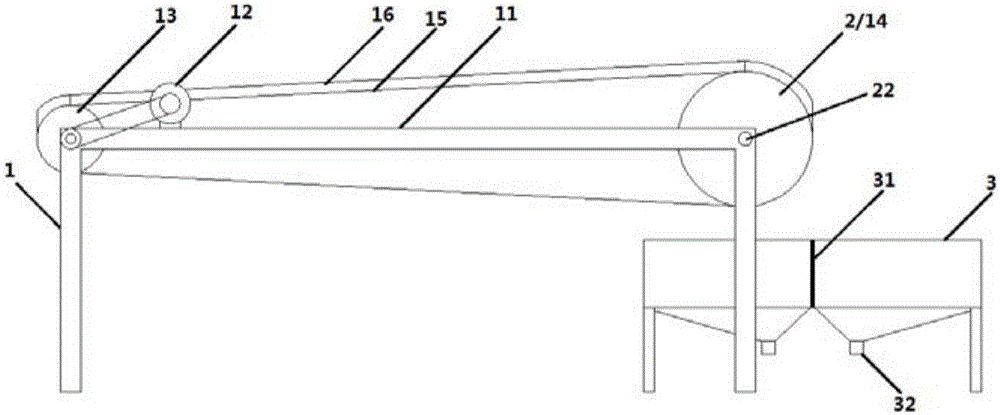

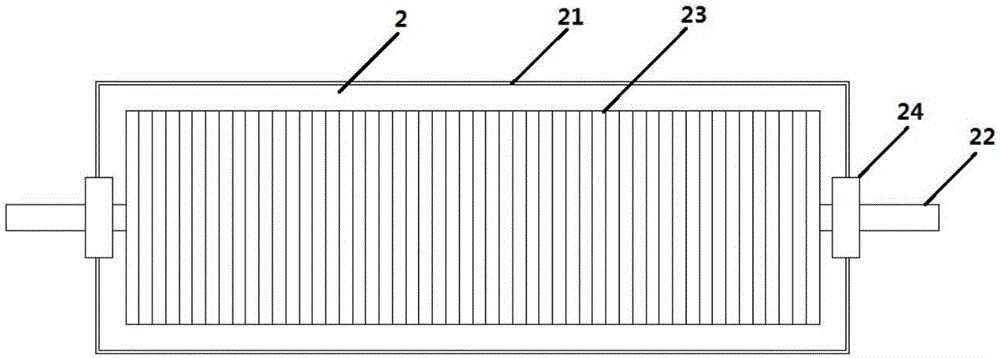

[0017] A belt conveyor type magnetic concentrator, such as figure 1 , 2 Shown, comprise belt conveyor 1, magnetic separation cylinder 2, hopper 3, described belt conveyor 1 comprises frame 11, motor 12, driving drum 13, driven drum 14, conveying belt 15, described magnetic separation cylinder 2 The driven roller 14 of the belt conveyor 1 is fixed on one end of the frame 11 through a bearing, the driving roller 13 is fixed on the other end of the frame 11 through a bearing, the conveyor belt 15 is wrapped on the two rollers, and the motor 12 is installed On the frame 11, the output shaft of the motor 12 is connected with the driving drum 13 and drives the driving drum 13 to rotate. The driving roller 13 drives the magnetic separation cylinder 2 to rotate through the conveyor belt 15. The hopper is arranged under the magnetic separation cylinder 2. The hopper 3 A partition 31 is arranged inside, and the partition 31 is in the same direction as the axis of the magnetic separatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com